A vibration and noise test bench for wind turbine yaw braking system

A wind turbine, yaw braking technology, applied in the testing of mechanical components, the testing of machine/structural components, instruments, etc., can solve the problems of life and reliability of mechanical systems, unable to perform effective performance testing, unable to yaw Brake system unstable vibration and other problems, to achieve the effect of stable and accurate output, easy disassembly and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

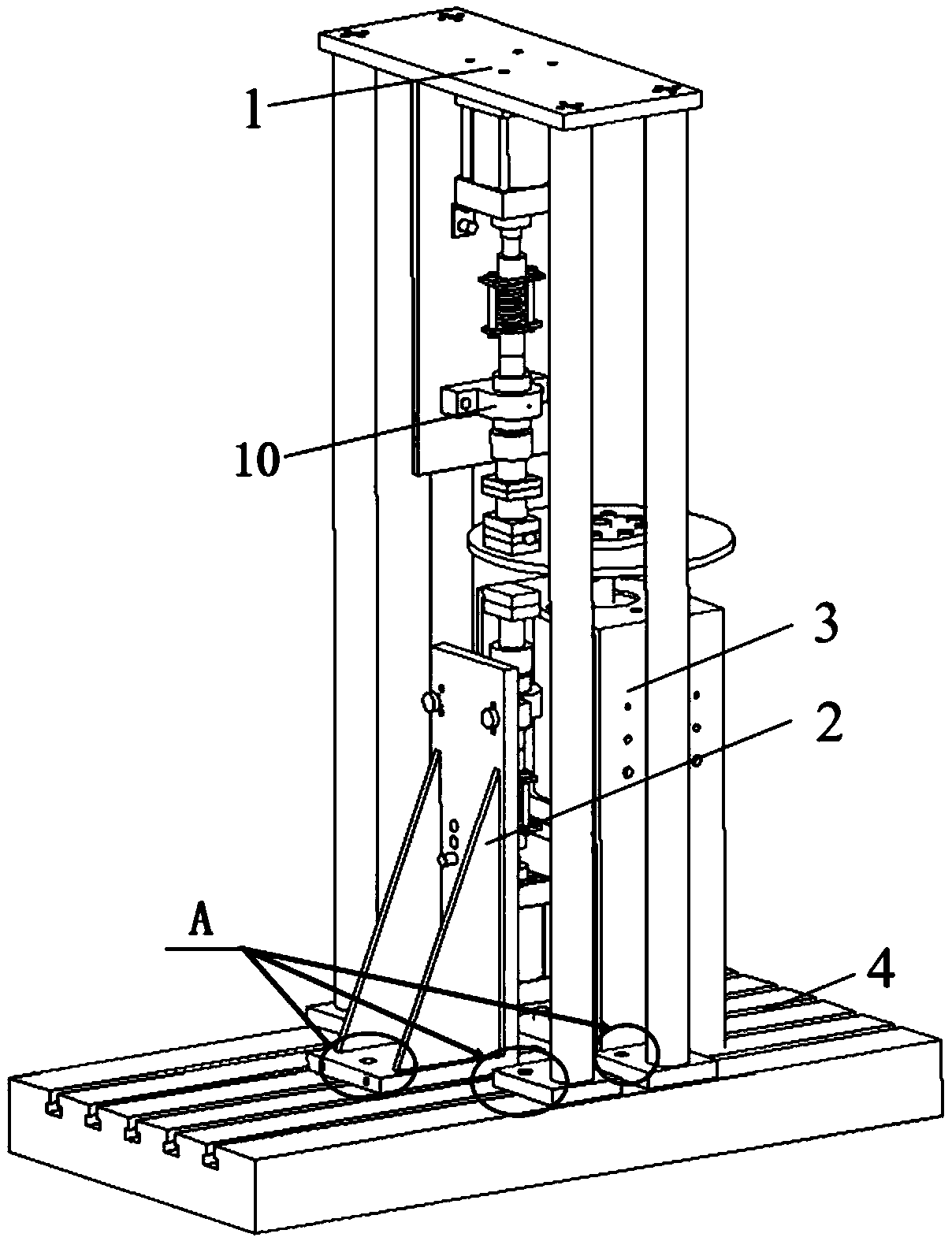

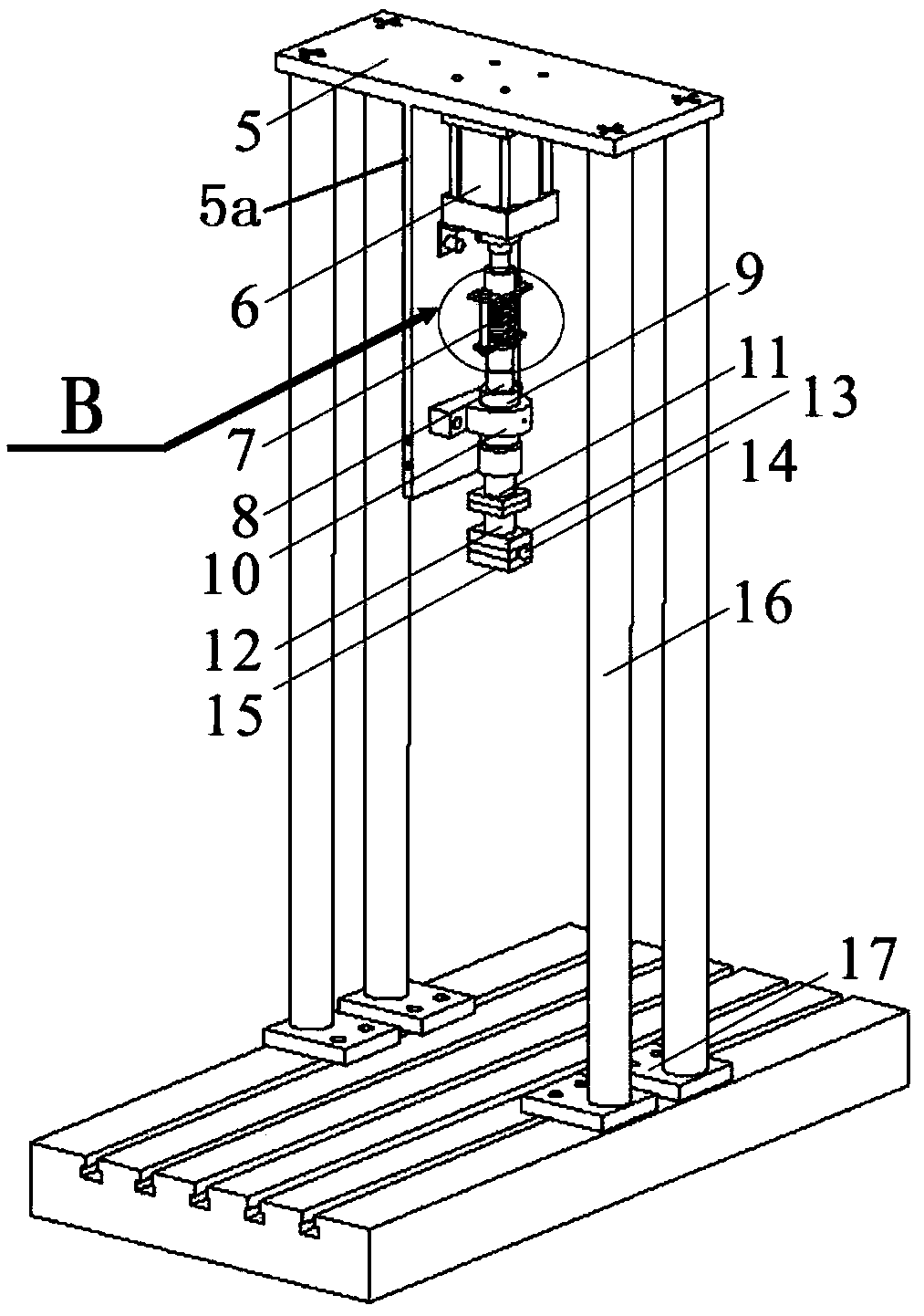

[0028] A vibration and noise test bench for a yaw brake system of a wind power generator, which is composed of an upper loading module 1, a lower loading module 2, a motor module 3 and a base 4; the base 4 is provided with a plurality of inverted T-shaped notches;

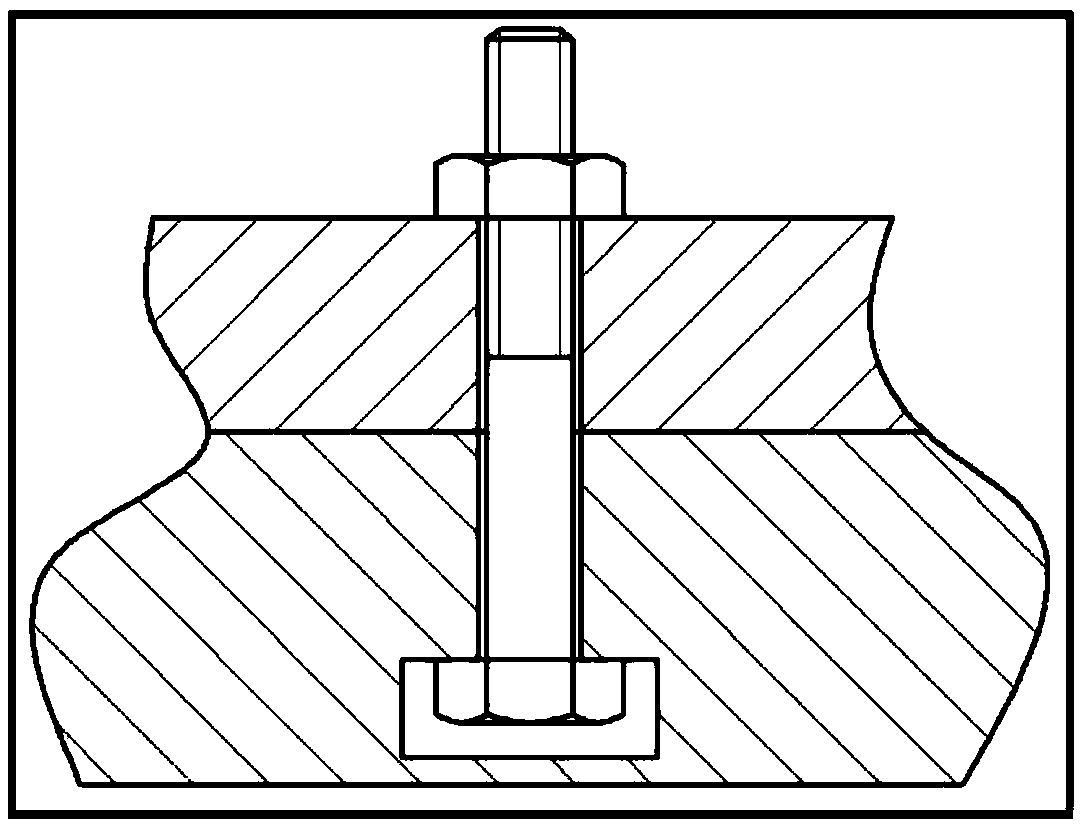

[0029] The structure of the upper loading module 1 is as follows: (the upper base plate, the four support columns and the installation plate 17 form the installation member) the upper base plate 5 is fixed on the top of the four support columns 16, and the bottom of the four support columns is fixed with a (rectangular) installation plate 17, And the mounting plate is fixed on the inverted T-shaped notch on the machine base 4 via bolts (it can be moved and fixed along the notch, see Figure 1a1 ), the upper cylinder 6 is fixed on the bottom surface of the upper bottom plate 5, the vertical plate 5a is fixed on the bottom surface of the upper bottom plate in a horizontal position, the upper bearing seat 10 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com