Four-quadrant-detector-based linear optical current sensor and detection method thereof

A four-quadrant detector and current sensor technology, applied in the direction of only measuring current, measuring current/voltage, measuring electrical variables, etc., can solve problems such as difficulty in meeting S-level requirements, large measurement errors, and large algorithm errors, and achieve real-time The effect of measurement, measurement resolution improvement, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

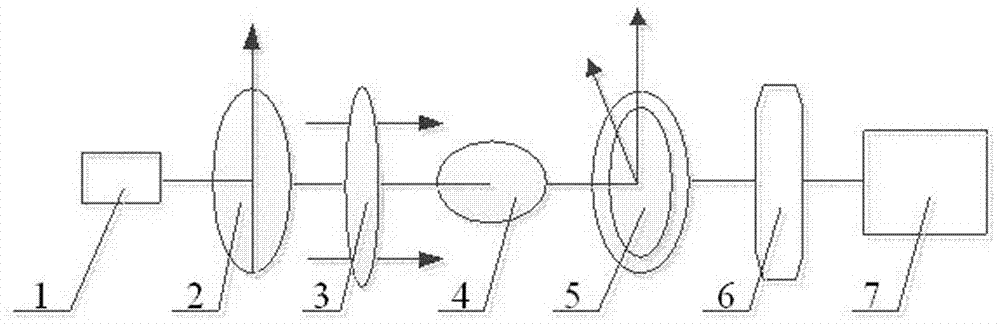

[0028] The present invention provides a linear optical current sensor based on a four-quadrant detector, such as figure 1 As shown, it includes a laser source 1, a polarizer 2, a magneto-optical film 3, a beam expander 4, a radial analyzer grating 5, a four-quadrant detector 6, and a signal processing system 7 that are sequentially arranged on the same optical path; A magnetic collecting ring with an air gap, the current-carrying wire to be detected passes through the magnetic collecting ring, and the magneto-optical film is arranged between the air gaps of the magnetic collecting ring.

[0029] Further, in this embodiment, the air gap of the magnetic collecting ring is less than 15mm, and the magnetic field is evenly distributed.

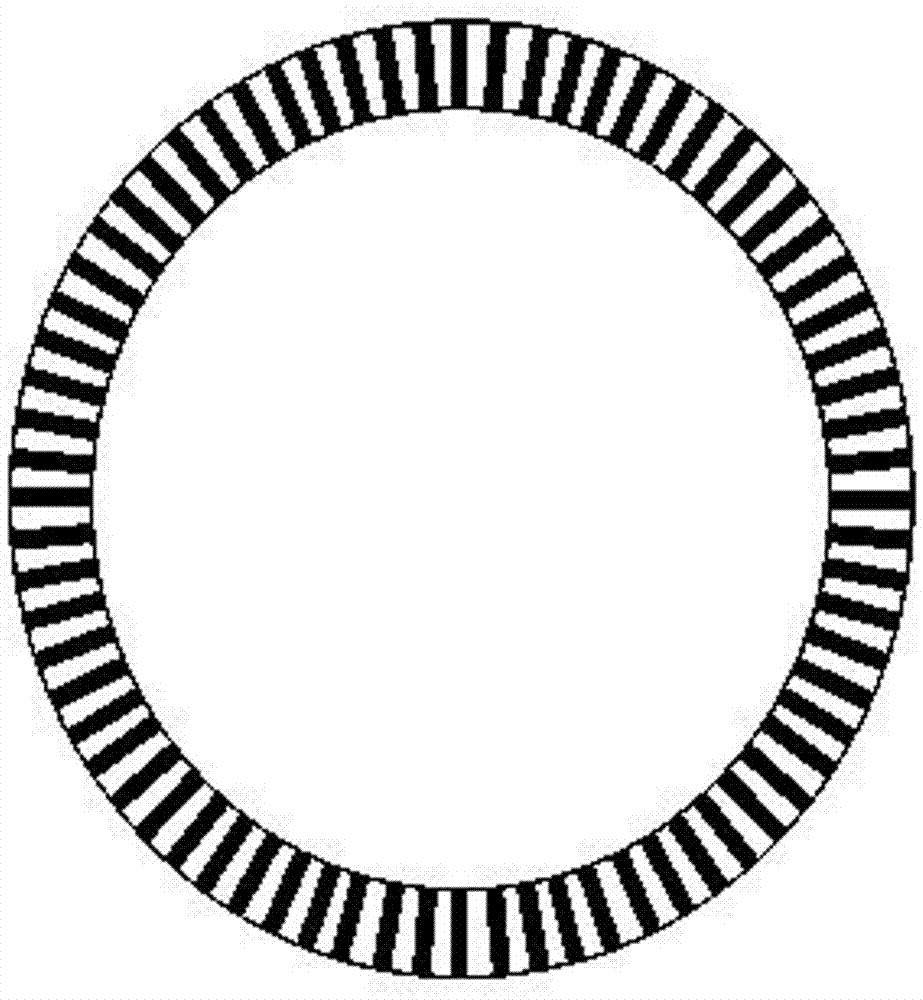

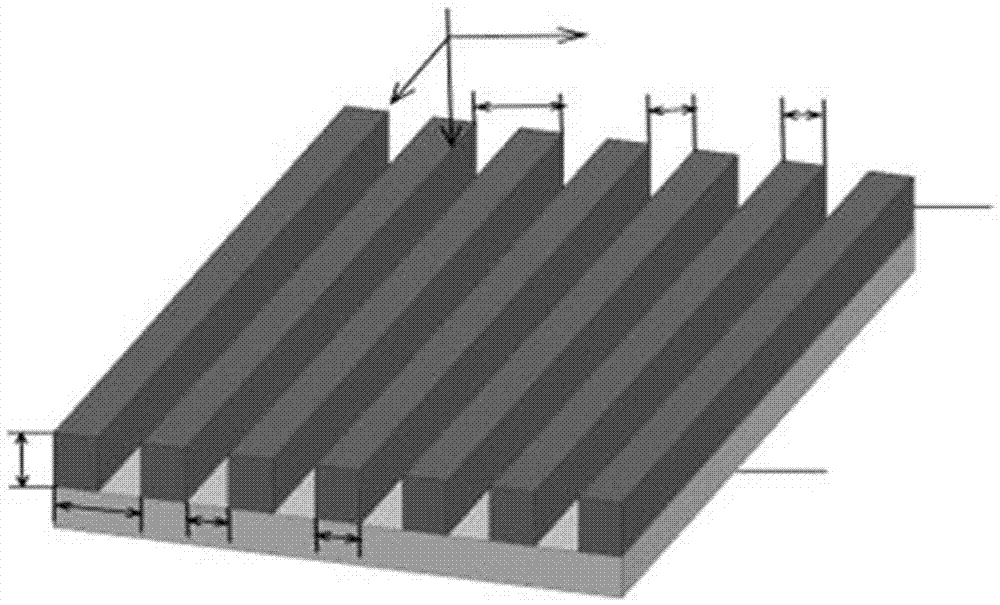

[0030] Further, in this embodiment, as figure 2 as well as image 3 As shown, the radial analyzer grati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com