Blast vibration safety judgment method considering crustal stress transient unloading

A transient unloading and blasting vibration technology, applied in special data processing applications, measuring devices, instruments, etc., can solve the problems of inaccurate safety assessment, can not well reflect the broadband characteristics of seismic waves, and achieve a wide range of frequency distribution. , the evaluation results are accurate and reliable, accurate and reliable vibration safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

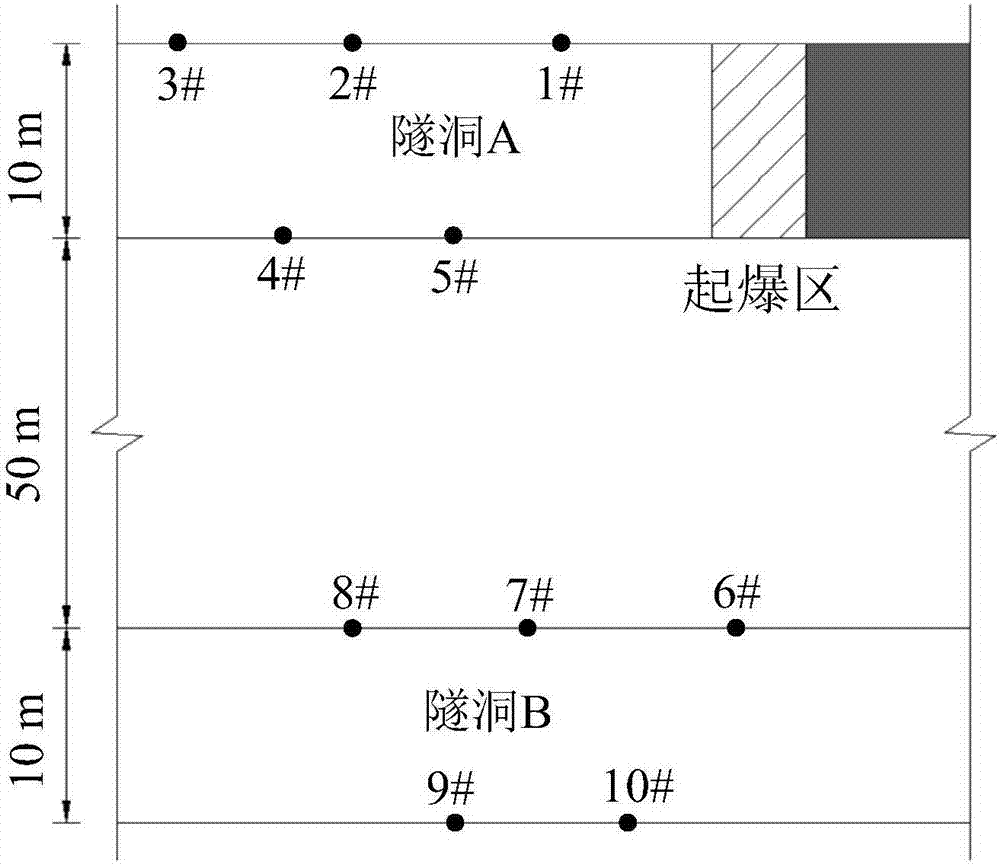

[0054] Engineering background: In a certain area, with the characteristics of large buried depth and high ground stress, a circular hydraulic tunnel A is excavated, and there is a completed hydraulic tunnel B near the excavated tunnel. A and B tunnels are in the At the same elevation, the parallel spacing is 50m, the tunnel radius is R=10m, and the initial ground stress around the tunnel is P 0 = 30MPa.

[0055] A method for judging the safety of blasting vibration considering the transient unloading of ground stress, comprising the following steps:

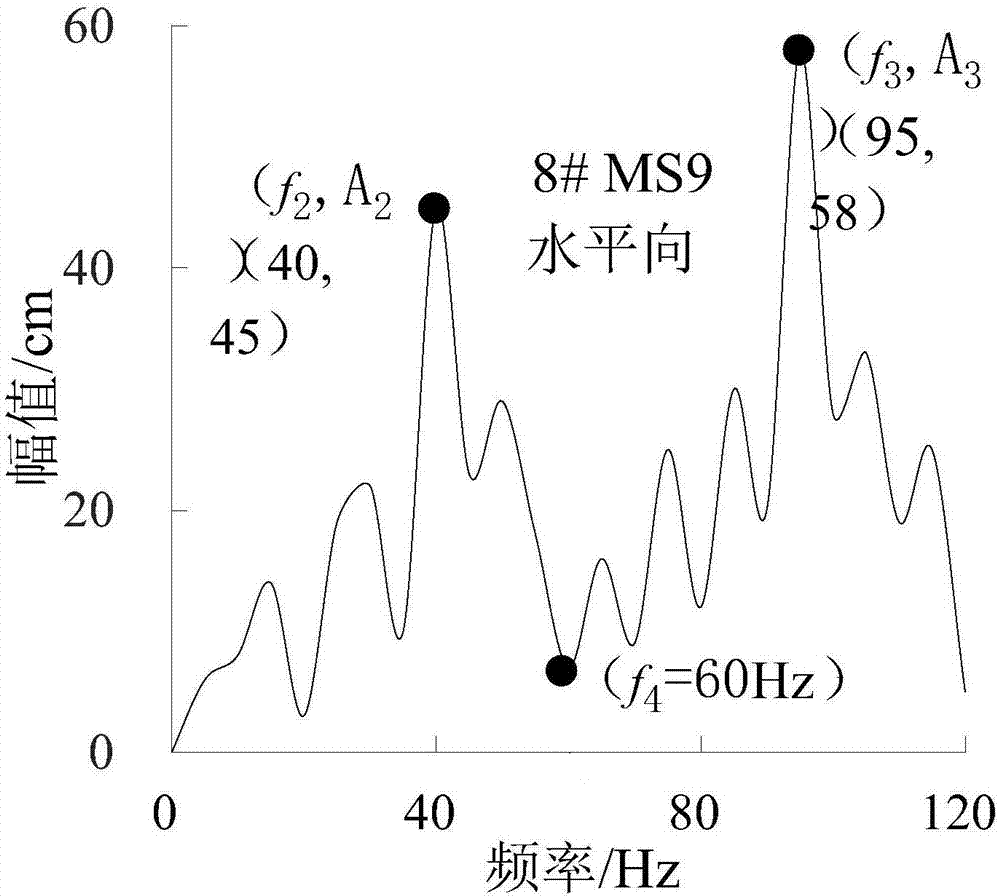

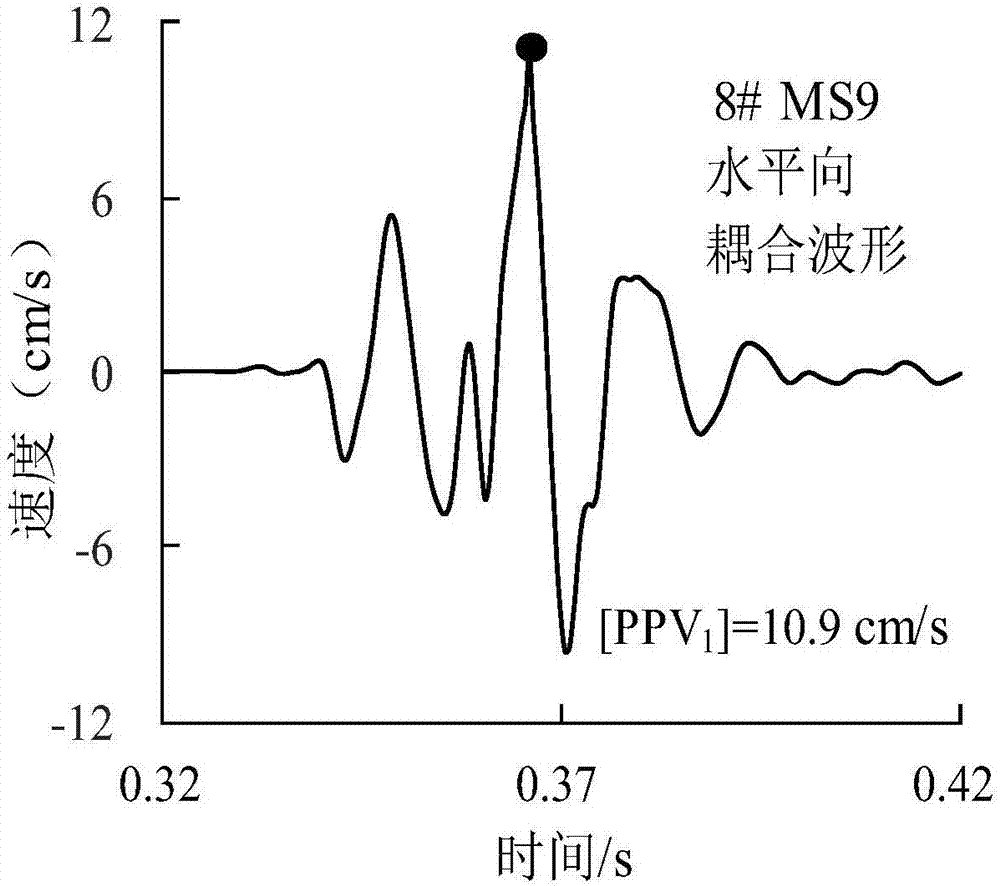

[0056] Step 1: Drill and charge at the face of tunnel A, using 8-stage delay detonators (MS1(0ms), MS3(50ms), MS5(110ms), MS7(200ms), MS9(310ms), MS11(460ms), MS13 (650ms) and MS15 (880ms)) are used as the detonation source, the aperture of the main blast hole is 90mm, the hole depth is 900cm, the hole distance is 240cm, the row distance is 200cm, and the length of the plugging section is 250cm. The φ60 or φ70mm charge rolls ar...

Embodiment 2

[0090] Figure 7 In the drilling and blasting excavation process of tunnel A, the number of surrounding rock vibration damage parts obtained by actual observation and the results of the surrounding rock safety evaluation using the existing evaluation means and the method of the present invention are respectively obtained, from Figure 7 It can be seen from the figure that compared with the existing blasting vibration safety criterion, the evaluation result is closer to the measured data and the evaluation accuracy is higher by adopting the blasting vibration safety criterion considering the transient unloading of ground stress provided by the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com