Method for forming quality online virtual detection and evaluation of ultra-thin-wall easily-deformed cylindrical element

A molding quality and quality evaluation technology, applied in the field of making it elastic, can solve the problems that the quality state after processing cannot be accurately obtained, and has not yet entered engineering applications, so as to achieve the effects of saving production costs, improving efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

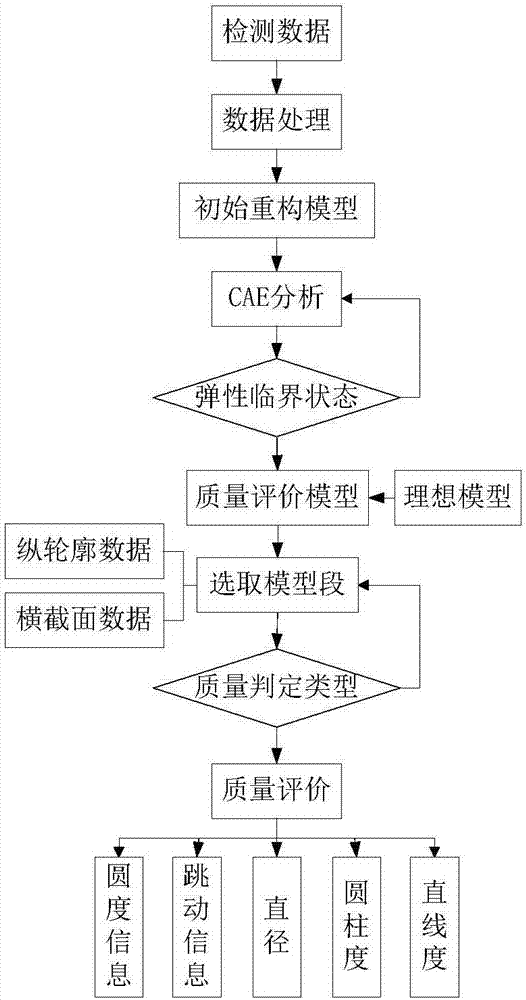

[0029] like figure 1 As shown, according to the surface model of the easily deformable cylindrical part reconstructed according to the online detection data, combined with the relationship between the material, the cylindrical part and the elastic deformation, the virtual uniform pressure is applied inside the cylindrical part to make it overcome its own gravity and other elasticity Deformation, to achieve the real state in actual use, obtain the quality evaluation model of the test piece, and compare it with the ideal processing state model to complete the quality evaluation. The main steps of a typical quality evaluation method are as follows:

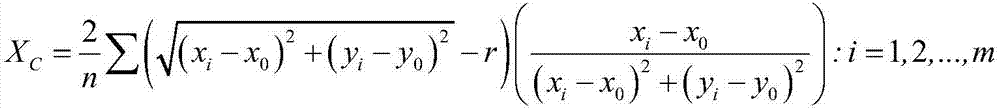

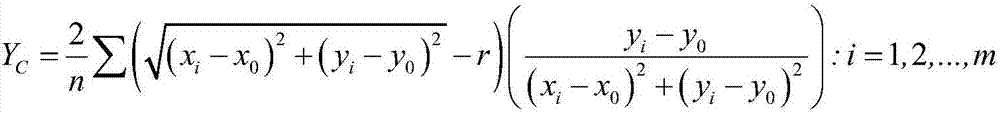

[0030]Step 1: Reconstruction model based on online detection data. Using non-contact measuring devices, adopt step-by-step or spiral data measurement methods to obtain the contour information of the workpiece processing status; through data analysis, elimination and processing, obtain the real displacement data of the cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com