Steel enterprise energy flow analysis method based on energy multi-stage transmission model

A transfer model and flow analysis technology, applied in resources, data processing applications, instruments, etc., can solve problems such as undiscovered patent documents, achieve good theoretical value and application value, improve the level of energy optimization, promote energy conservation, emission reduction and sustainability. The effect of continuous development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0055] A method for analyzing energy flow in iron and steel enterprises based on a multi-stage energy transfer model, comprising the following steps:

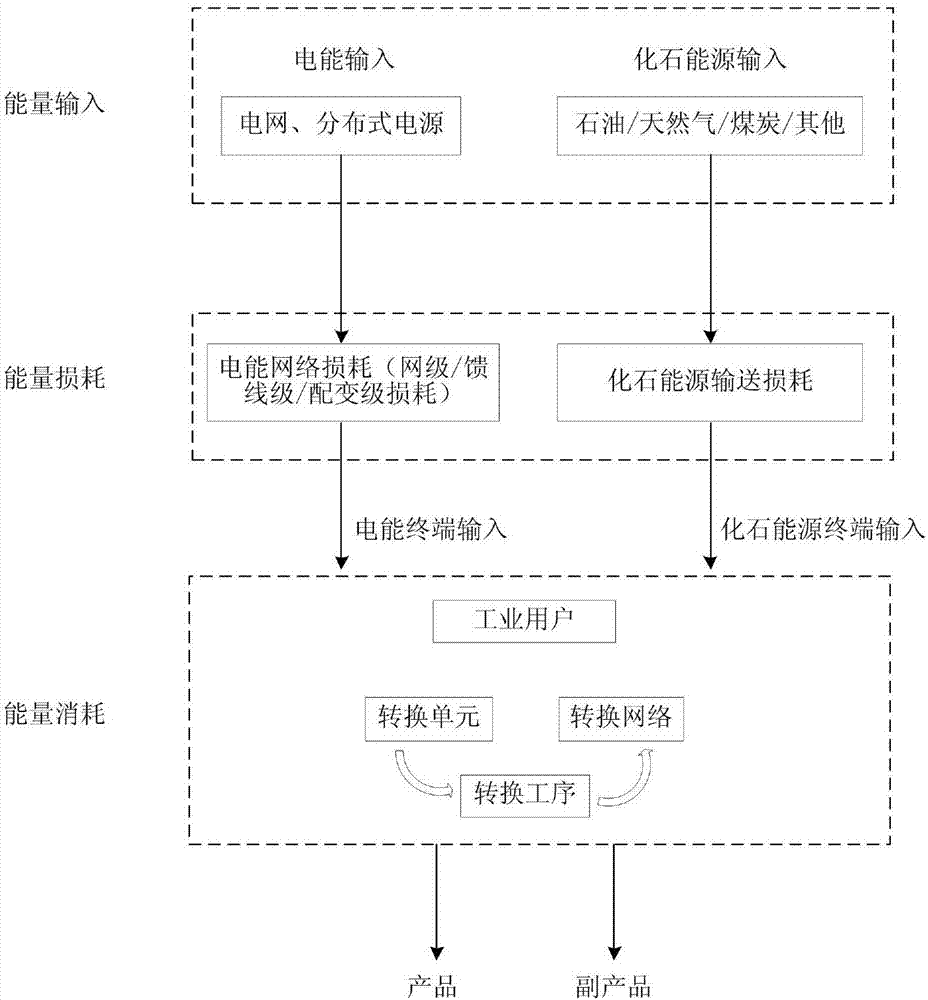

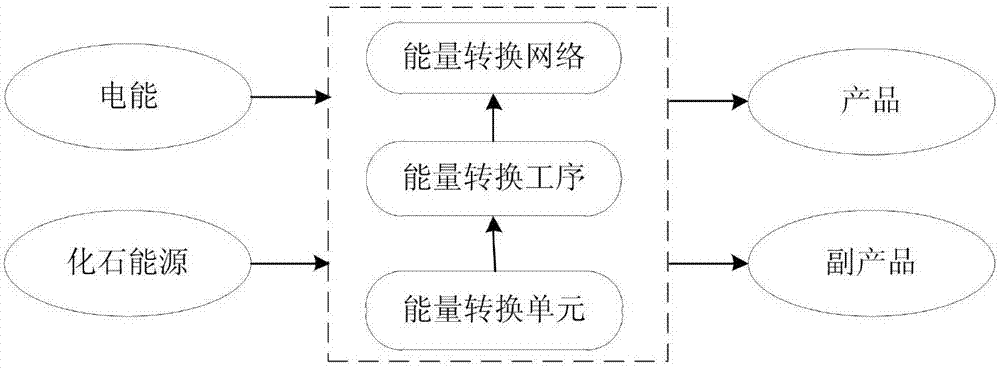

[0056] Step 1. Establish a multi-stage energy transfer model for iron and steel enterprises including the entire energy flow process of energy input and energy utilization, such as figure 1 shown;

[0057] The energy multi-level transfer model of iron and steel enterprises includes energy input and energy utilization. The energy input of iron and steel enterprises includes electric energy input and fossil energy input, and energy utilization is divided into energy consumption and energy loss.

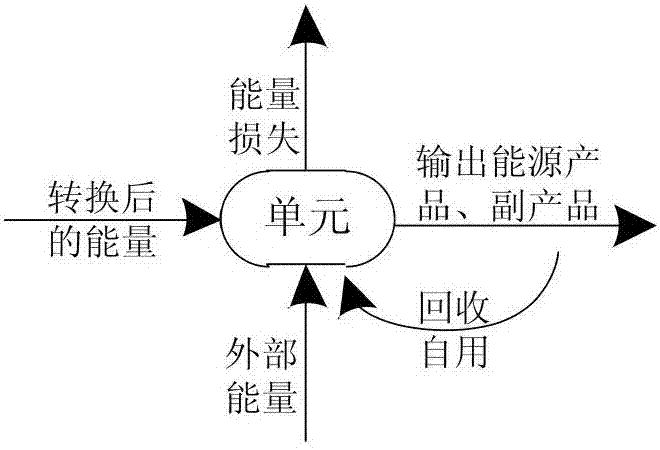

[0058] Energy utilization refers to the energy flow of energy in iron and steel enterprises through cascade utilization and partial loss; energy consumption refers to the energy consumed by iron and steel en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com