Silicon-carbon composite granules and preparation method and application therefor

A silicon-carbon composite and carbon nanotube composite technology, which is applied in the fields of nanotechnology, electrical components, electrochemical generators for materials and surface science, etc., can solve the problem of only reversible specific capacity, unfavorable practical application, and low material specific capacity. and other problems, to achieve the effect of simple and easy-to-control production process, overcoming easy powdering and falling off, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Some embodiments of another aspect of the present invention provide a method for preparing silicon-carbon composite particles, which includes:

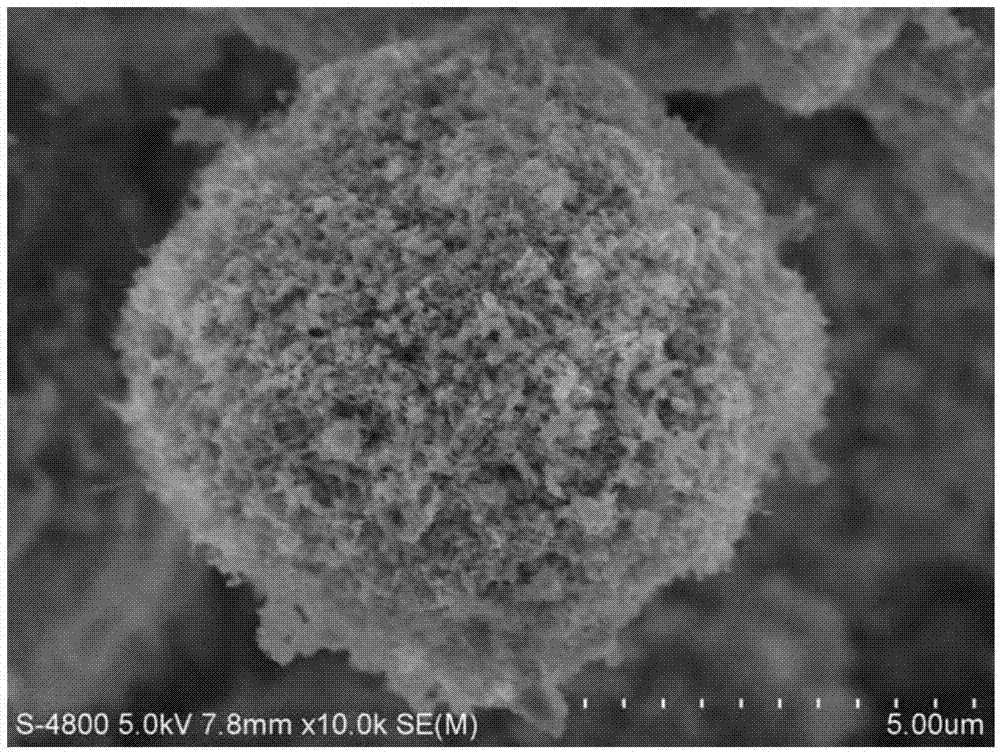

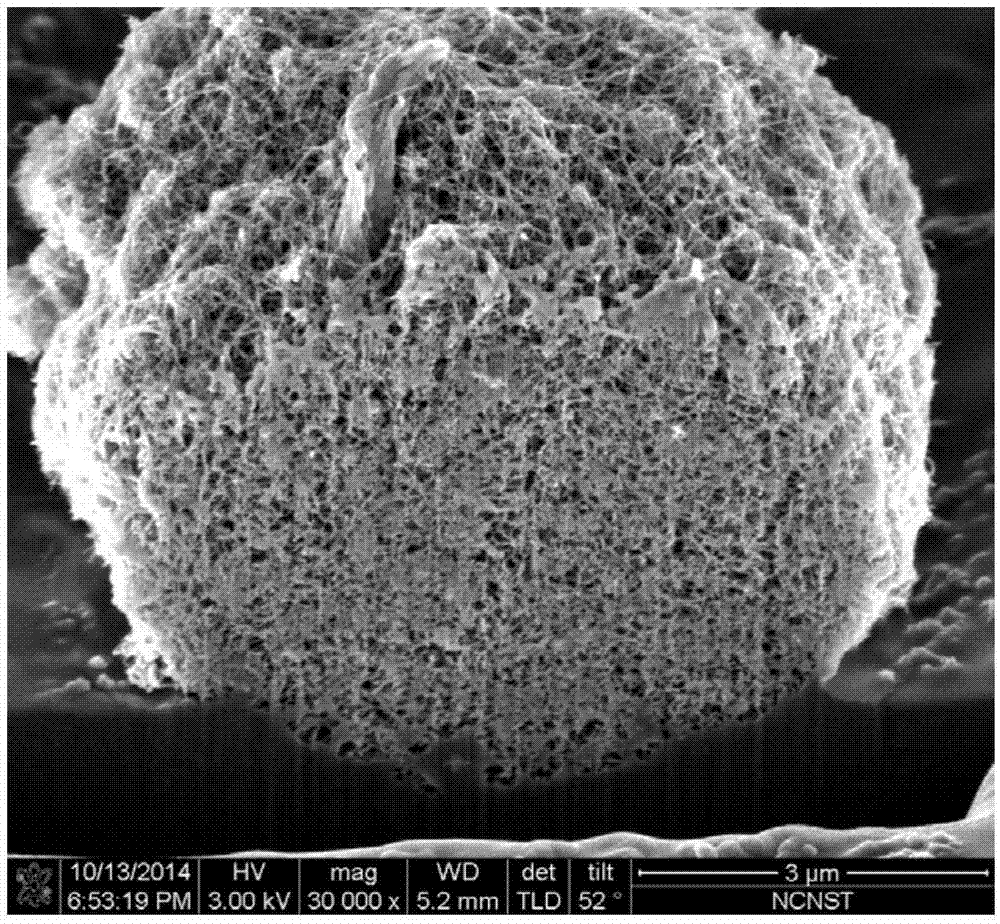

[0044] Nano-silicon material and carbon nanotubes are uniformly dispersed in a solvent, and then nano-silicon-nanotube composite particles with a porous structure are prepared by spray granulation technology.

[0045] The nano-silicon-nanotube composite particle and the organic carbon source are fully mixed in a liquid phase system, and then coated with organic cracked carbon, so as to obtain the silicon-carbon composite particle.

[0046] In some preferred embodiments, the preparation method includes: uniformly dispersing nano-silicon material and carbon nanotubes in a solvent to form a uniform dispersion of nano-silicon and carbon nanotubes.

[0047] Further, the solid content in the uniform dispersion is preferably 1-50 wt%, especially preferably 1-10 wt%.

[0048] Further, the solvent includes a solvent formed by mixing wa...

Embodiment 1

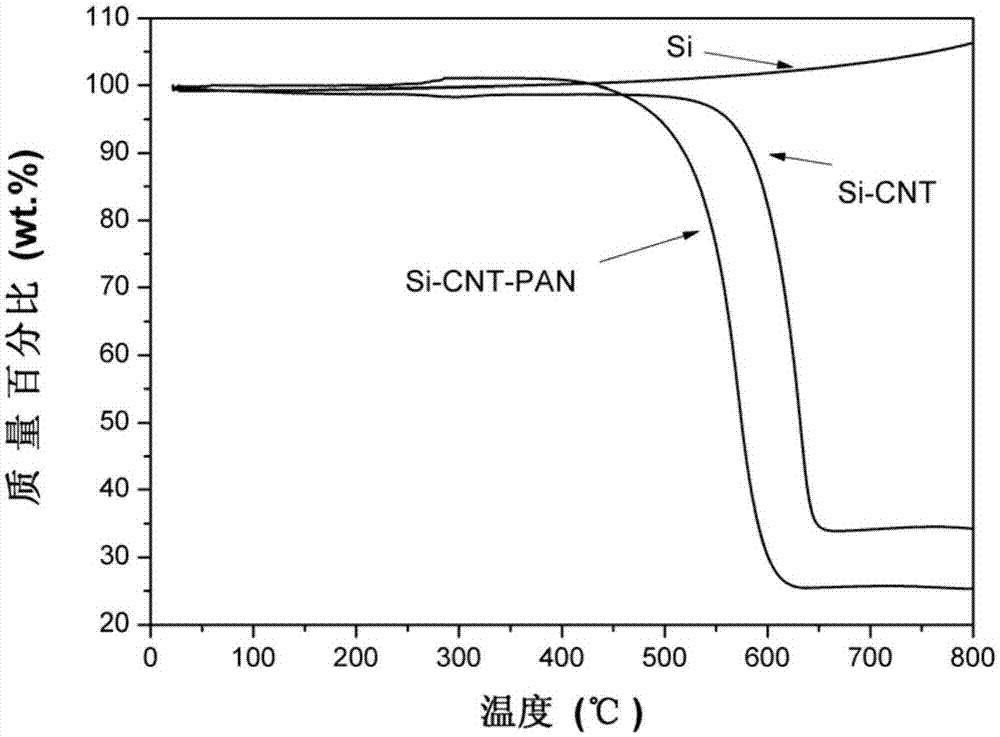

[0073] Mix absolute ethanol and deionized water according to the volume ratio of 10:100; then add nano-silicon to the above solution, and magnetically stir to disperse nano-silicon evenly; add carbon nanotubes to the above solution to make the total solid concentration 10g / L, the mass ratio of nano-silicon in the solid particles is 30%, continue to stir, so that the solid particles are uniformly dispersed in the solution; under stirring, the above-mentioned solution is ultrasonically treated for 1h, so that the nano-silicon and carbon nanotube solution become Uniformly dispersed suspension; the above suspension is sprayed and granulated, where the air inlet temperature is set at 150°C to 200°C, the outlet temperature is set at 70°C to 100°C, and the spray speed is 500ml / hour to 10 liters / hour, the spray pressure is set to 40MPa, and the injection volume is set to 500mL / h. Collect the prepared samples in a collection bottle.

[0074] The resulting sample was added to a DMF (di...

Embodiment 2

[0077] Mix ammonia water, absolute ethanol and deionized water in a volume ratio of 1:10:100; add sucrose, nano-silicon, and carbon nanotubes to the above solution in sequence, and the mass ratio of the three is 20:6:4. Make the total solid concentration be 10g / L, the mass ratio of nano-silicon in the solid particles is 40%, the above-mentioned solution is ultrasonically treated for 1h under stirring, and the above-mentioned suspension is sprayed and granulated, wherein the air inlet temperature is set to 150°C-200°C, the outlet air temperature is set at 70°C-100°C, the spray speed is 500ml / h-10l / h, the spray pressure is set at 40MPa, and the injection volume is set at 500mL / h. Collect the prepared samples in a collection bottle.

[0078] The obtained sample was roasted in a tube furnace, protected by an inert gas, heated to 700°C, kept for 3 hours at a heating rate of 5°C / min, and cooled to room temperature to form the silicon-carbon composite particles.

[0079] Using SEM t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com