Tension force film type wave energy power generation device

A power generation device and wave energy technology, applied in electromechanical devices, ocean energy power generation, electrical components, etc., can solve the problems of difficult maintenance, large size of the device, complicated installation and construction, etc., achieve high energy harvesting efficiency, reduce volume and weight, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

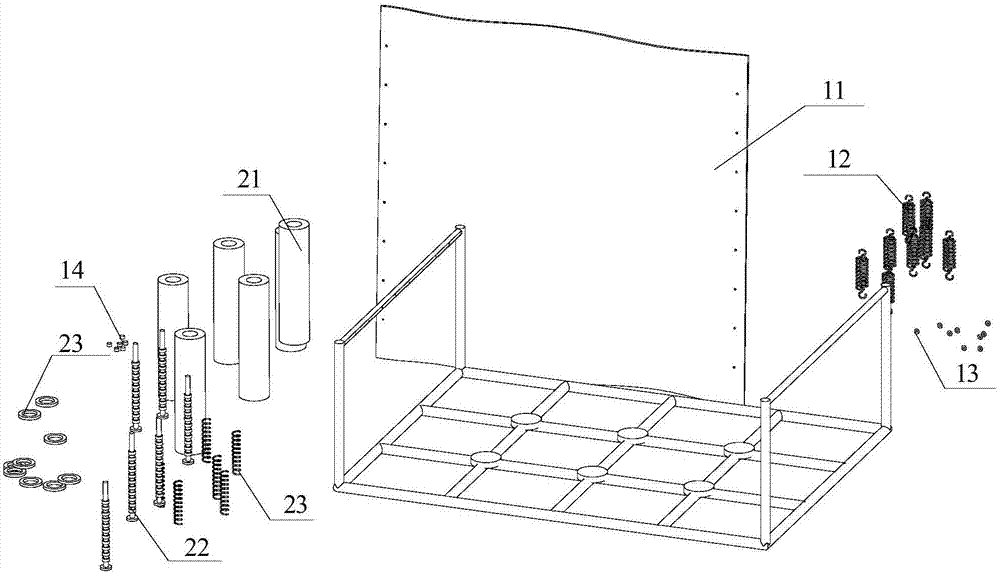

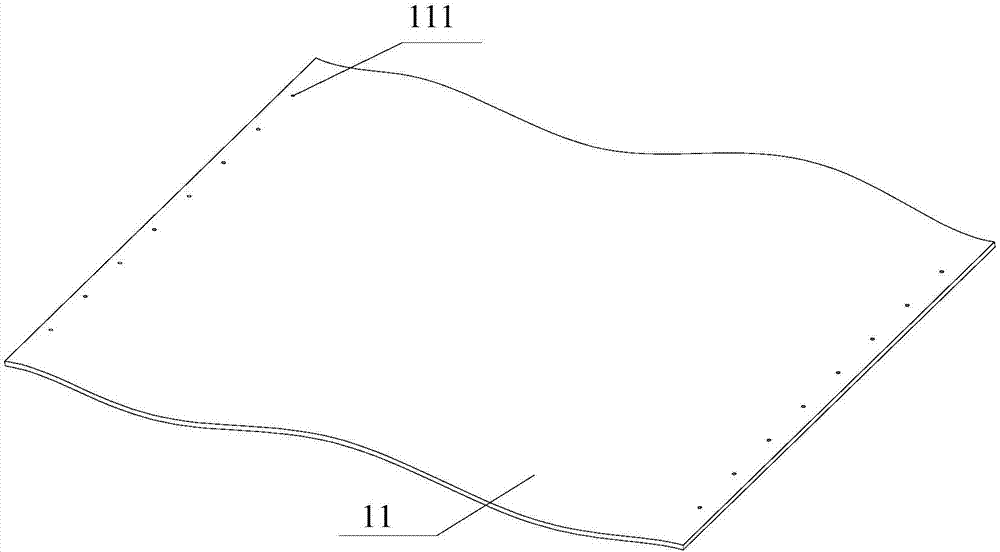

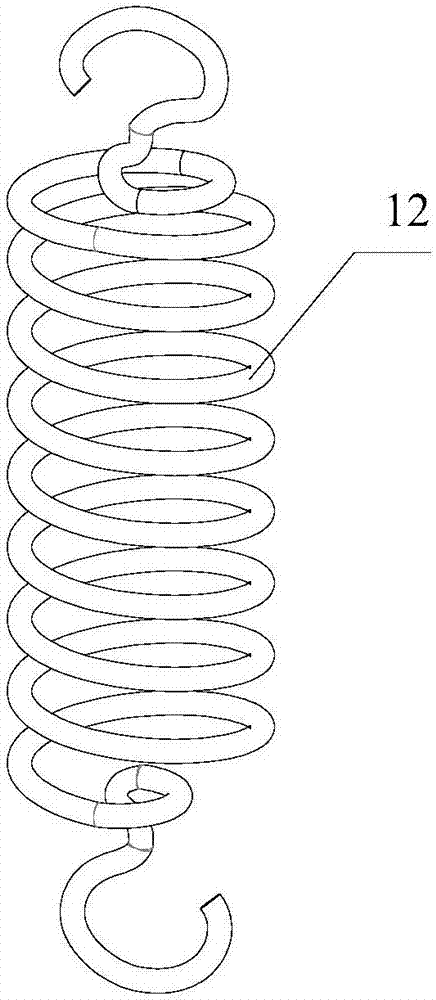

[0026] Such as Figure 1 to Figure 11 As shown, a tension membrane type wave energy generating device of the present invention includes a tension membrane 11 , a tension spring 12 , a gasket 13 , a strong magnet 14 , a linear generator 2 , and an underframe 3 . Tension film 11 is provided with tension film round holes 111 along the outer edge of both sides in the width direction, and the arc-shaped hook at one end of extension spring 12 passes through gasket 13 and the round holes 111 on the edge of tension film 11 to keep connected with tension film 11 successively. The arc-shaped hook at the other end of the extension spring 12 is kept connected with the round hole 31 of the bottom frame 3 in the floating module. The gasket 13 is an annular metal gasket fixed on the upper and lower surfaces of the tension membrane 11 . The strong magnet 14 is divided into an upper part 141 and a lower part 143 , wherein the lower end surface of the lower part has a screw hole 142 inwardly at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com