Manufacturing method for picture core of iron picture and iron picture artistic lamp comprising picture core

A manufacturing method and technology for iron paintings, which are applied in decorative arts, components of lighting devices, and damage prevention measures for lighting devices, etc., can solve problems such as difficulty in making iron paintings, inability to further improve efficiency, and insufficient connotation of iron paintings. The effect of production costs

Inactive Publication Date: 2017-06-23

马洪斌

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Another disadvantage of iron painting products is: A: Artists need to learn and practice for a long time; B: A single variety of iron painting is produced in batches, which cannot further improve efficiency; C: Iron paintings with smaller specifications (length and width less than 6 cm) are difficult to make; D: Iron paintings The cost cannot be greatly reduced; E: The connotation of iron painting is not rich enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

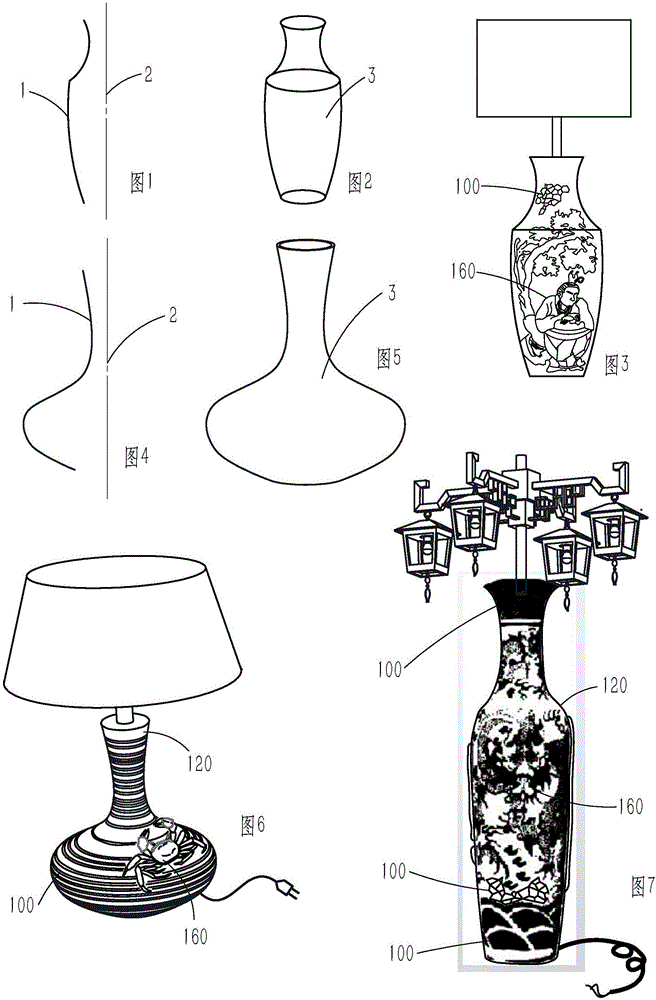

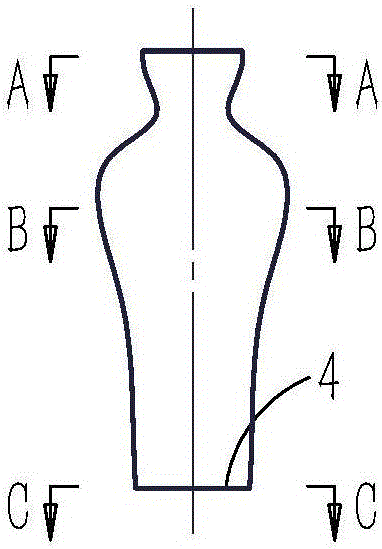

The invention provides a manufacturing method for a picture core of an iron picture and an iron picture artistic lamp comprising the picture core, and belongs to the technical field of traditional iron picture artware. According to the technical scheme adopted for overcoming defects of traditional products, the manufacturing method for the picture core of the iron picture is characterized in that all the picture core or part of the picture core is obtained through die casting by means of a die; the manufacturing method comprises the specific steps that the original iron picture is divided into a plurality of blocks, the die for the blocks is manufactured, solid bodies of the blocks are obtained through casting by means of the die, and the different solid bodies are combined to form the complete picture core; or the solid bodies and the original iron picture which cannot be cast easily are combined to form the complete picture core; and the cast solid bodies are made of any one of or a mixture of two or more of metal materials, non-metal materials and organic materials.

Description

A manufacturing method of iron painting core and iron painting art lamp including the same technical field The invention relates to a method for manufacturing an iron painting core and an iron painting art lamp including the same, belonging to the technical field of traditional iron painting handicrafts. Background technique According to the local historical data of Wuhu, Wuhu Iron Painting was born in 1687 (the 26th year of Qing Emperor Kangxi) with a history of 329 years. It was created by Tang Tianchi, an artist of Wuhu Iron Painting, known as "Wuhu Iron Painting". In 2006, Wuhu iron painting forging technique was approved by the State Council and included in the first batch of national intangible cultural heritage list. Iron painting is made of low-carbon steel. Artists use hammer as pen, iron as ink, anvil as paper, furnace as inkstone, and wrought iron as painting. After being forged, welded, drilled, shaped, rust-proofed, and painted, it is lined with a white back...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B44C3/00B44C3/04F21S9/03F21V15/02F21V19/00F21V33/00F21Y115/10

CPCB44C3/00B44C3/04F21S9/032F21V15/02F21V19/001F21V33/0032

Inventor 马洪斌

Owner 马洪斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com