Battery pack

A technology of battery packs and battery modules, which is applied to battery pack parts, circuits, electric vehicles, etc., can solve the problems of increasing the weight of the whole vehicle, which is not conducive to the lightweight of the body, and increases the manufacturing cost of the bicycle, so as to avoid resonance and abnormal noise , Improve the rigidity performance and avoid the effect of durable cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

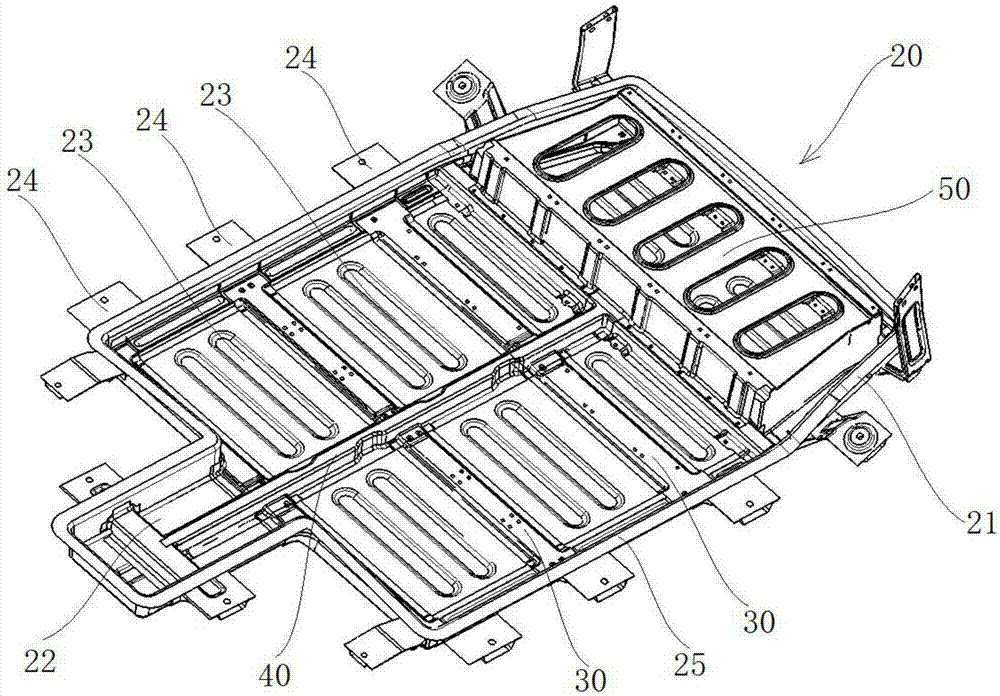

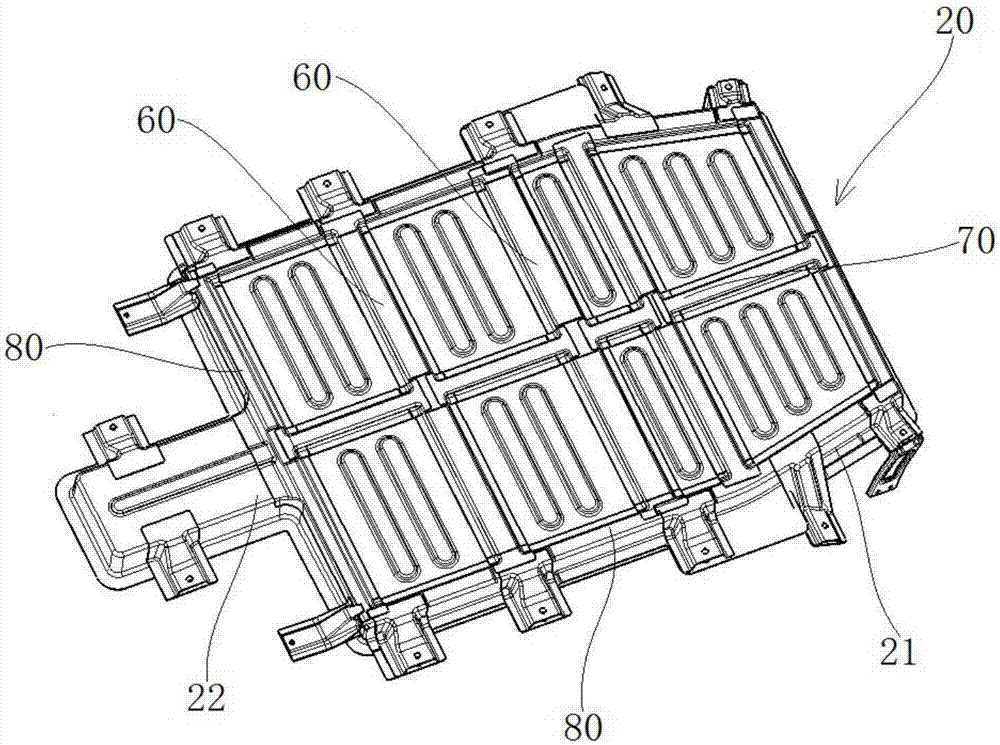

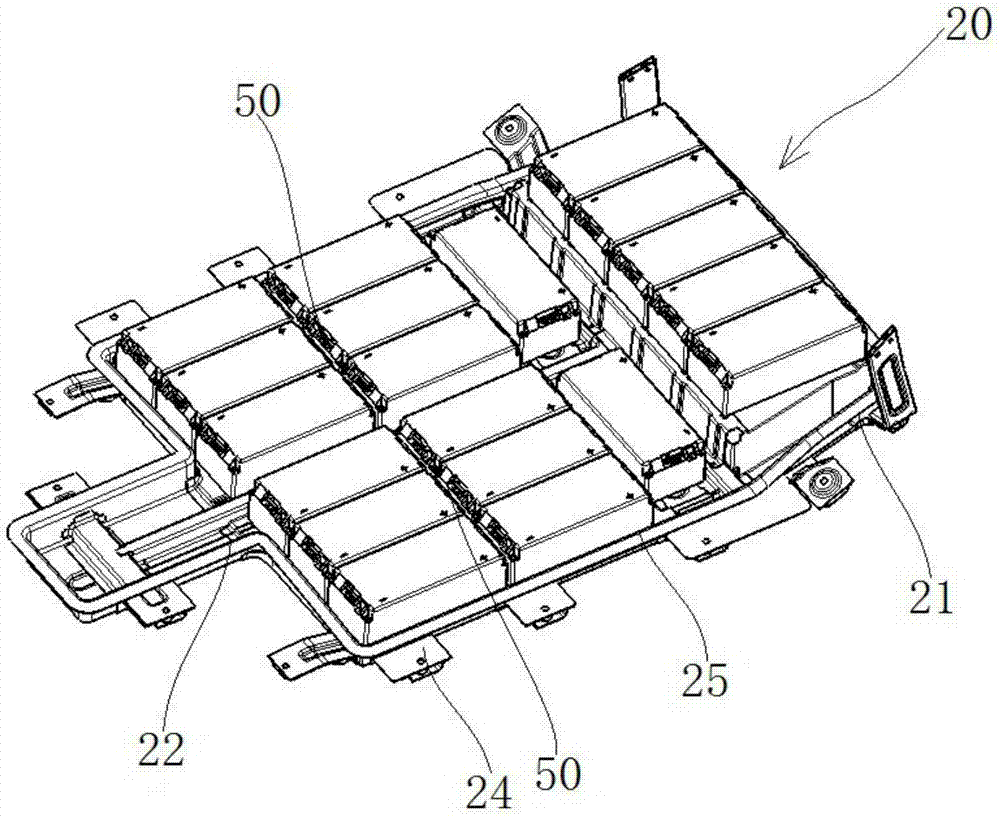

[0011] combined with Figure 1~4 The present invention is further described:

[0012] A battery pack, comprising upper and lower casings 10 and 20 connected correspondingly, the upper bottom surface of the lower casing 20 is respectively provided with an inner beam 30 and an inner longitudinal beam 40 in the direction of vehicle width and vehicle length. The longitudinal beam 40 is located in the middle of the lower case 20 , the inner crossbeam 30 is arranged perpendicular to the inner longitudinal beam 40 , and the battery module bracket 50 is arranged on both sides of the inner longitudinal beam 40 and connected with the inner crossbeam 30 and fixed in the cavity of the lower case 20 indoor. Spot welding is used to connect the inner beam 30, the inner longitudinal beam 40 and the lower shell 20, and the inner beam 30 and the inner longitudinal beam 40 are vertically arranged on the upper bottom surface of the lower shell 20, forming a similar "shi" shape, which strengthens...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap