Heavy tray lifting conveyor

A technology of conveyors and heavy discs, which is applied in the field of heavy disc lifting conveyors, can solve the problems of high use and maintenance costs of the hydraulic system, affect the practicability of the lift, and the hydraulic system cannot be used for height drop conveying equipment, etc., so as to reduce the use of forklifts , to avoid accidents, the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

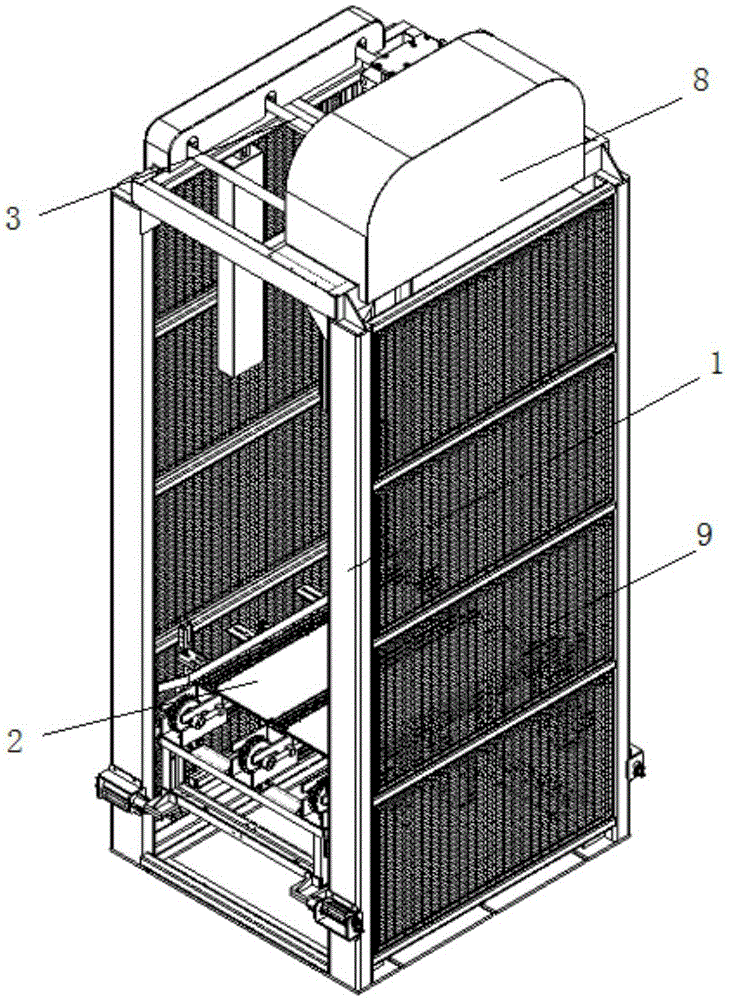

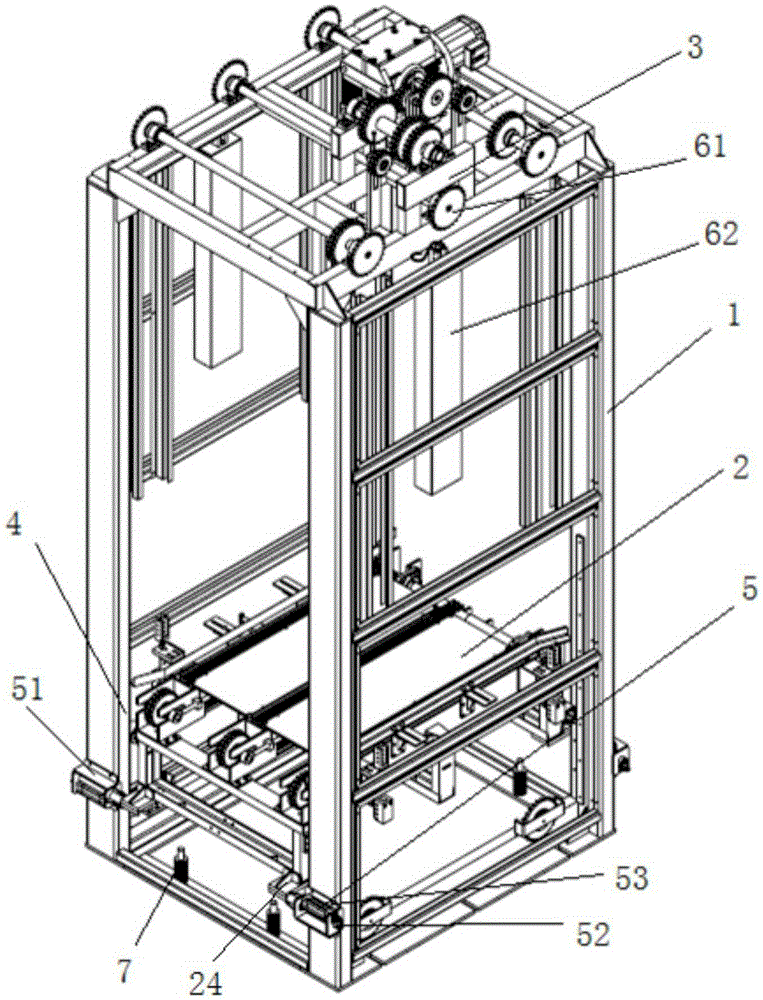

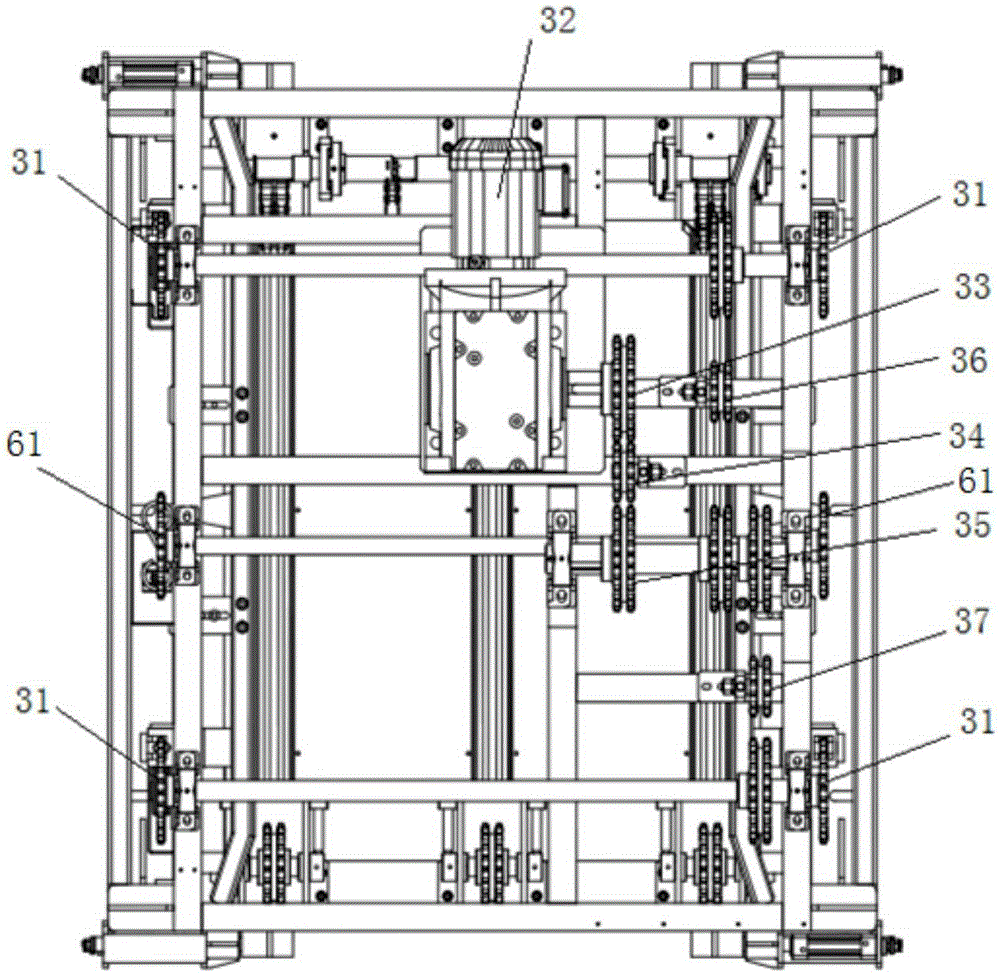

[0032] like Figure 1~6 As shown, a heavy disk lifting conveyor includes a frame 1, a lifting transfer platform 2 and a lifting power unit 3, the lifting and transferring platform 2 is installed in the frame 1, and the lifting power unit 3 is connected to the lifting and moving The stage 2 is characterized in that the lifting power unit 3 is a sprocket transmission mechanism, including a top sprocket 31 installed on the top of the frame 1, a deceleration unit and a top sprocket 31 installed at the bottom of the frame 1. The bottom sprocket 38, the deceleration unit is connected to the top sprocket 31, and the top sprocket 31 is connected to the bottom sprocket 38 through a chain to form a vertical transmission structure, and the middle part of the chain is fixedly connected to the lifting and transferring platform 2. The lifting and transferring platform 2 is provided with a lifting chain fixing seat 25 for fixing the chain. The outer side of the lifting conveyor frame 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com