Variable cross-section beam and suspension cable combined bridge structural system

A bridge structure and variable cross-section beam technology, which is applied in the direction of suspension bridges, bridges, bridge construction, etc., can solve the problems of suspension bridge structure bridges not being popularized and applied, high casting costs of large-size saddles, and large spanning capacity of suspension bridges, etc., so as to achieve low production difficulty , to avoid the effect of high cost and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

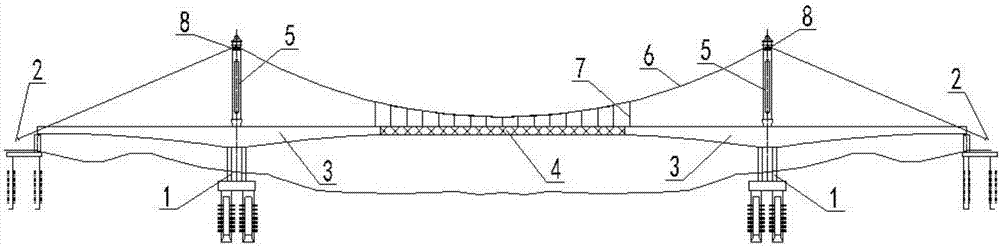

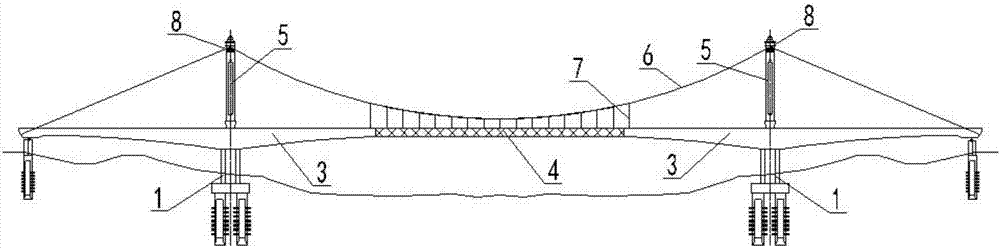

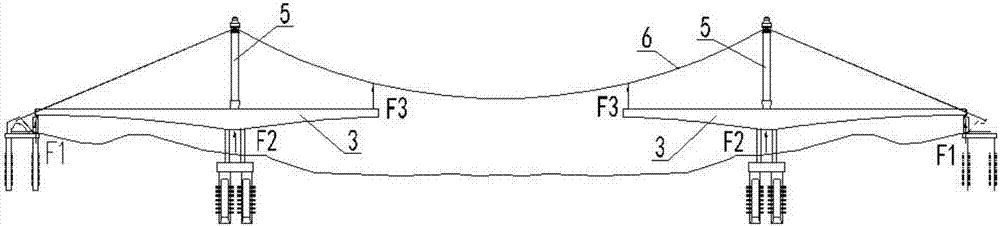

[0024] see figure 1 , figure 2 , in the present embodiment, the structural form of the bridge structure system with variable cross-section beams and suspension cables is: the bridge structure system is to set the variable cross-section main girder 3 on the piers 1 at both ends, and between the variable cross-section main girders 3 at the two ends, located at the main Set the main girder 4 of constant section in the middle of the span; set the low-height bridge tower 5 on the pier top of the variable-section main girder 3, set the saddle 8 on the top of the low-height bridge tower 5, and use the saddle 8 and the two ends to anchor the structure The main suspension cable 6 is set, and the suspender 7 is arranged in the middle section of the main suspension cable 6. The main beam 4 of equal cross-section is lifted by the suspender 7, and the suspension system is composed of the saddle 8, the main suspension cable 6 and the suspender 7. , to realize the long-span main span.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com