Factory production line material carrying mechanical arm hydraulic system

A technology of hydraulic system and manipulator, applied in the field of hydraulic system, can solve the problems of easy failure and insufficient performance, and achieve the effect of preventing self-sliding or overspeed, improving performance and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

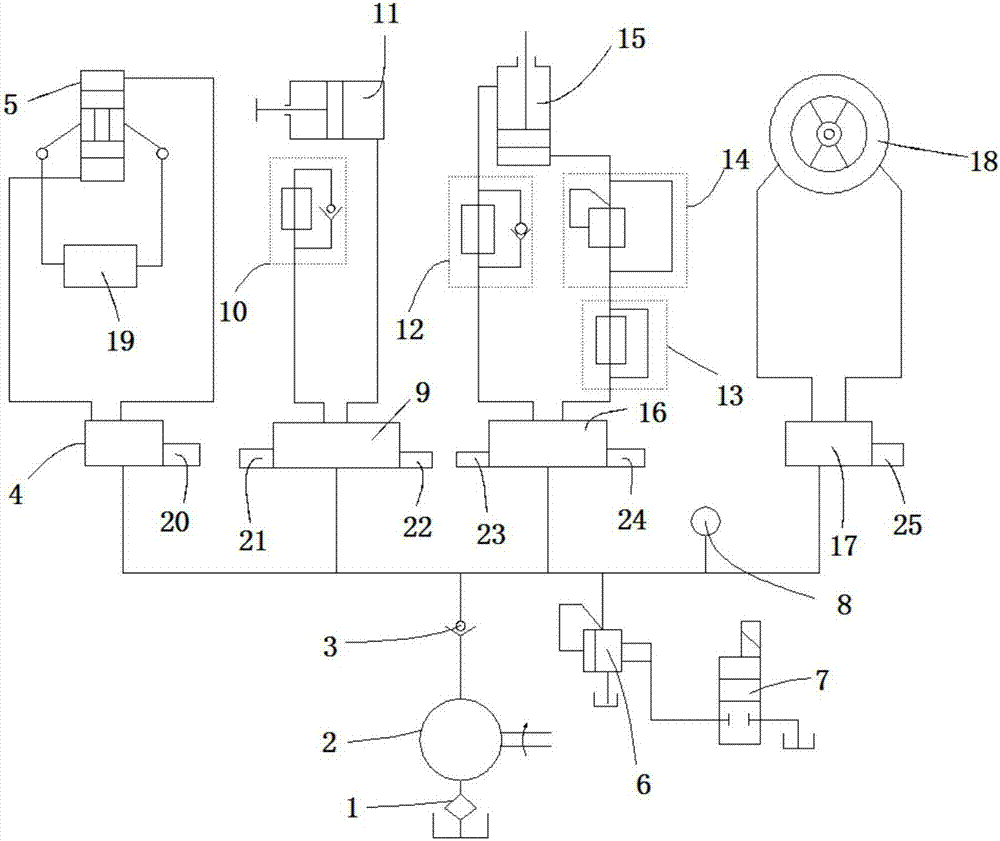

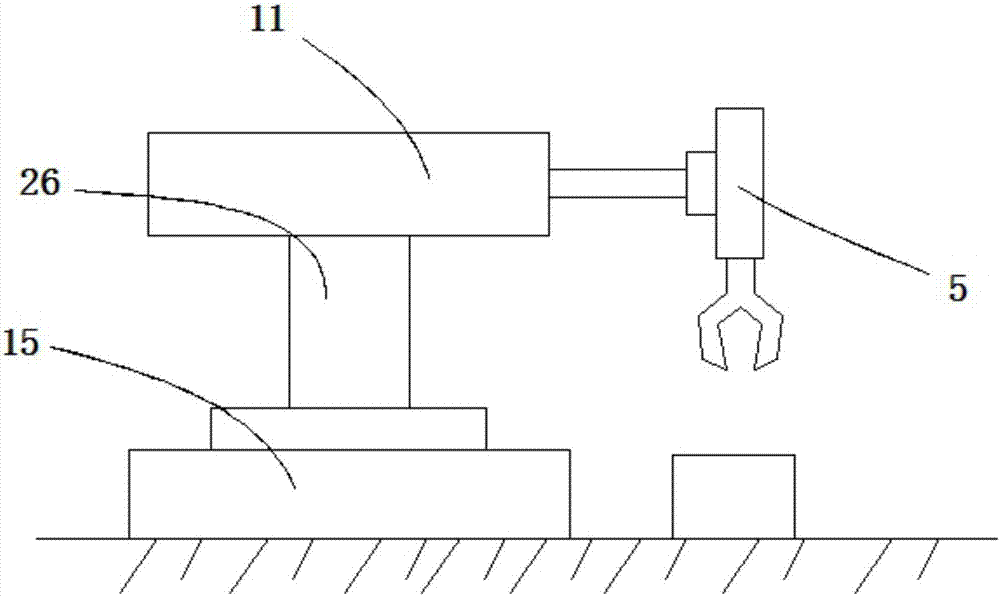

[0017] refer to Figure 1-2 , a factory production line material handling manipulator hydraulic system, including a manipulator 26 and a hydraulic system that controls the manipulator 26 to grab and carry a workpiece 19. The hydraulic system includes an oil filter 1, a one-way quantitative valve 2, a one-way valve 3, a first Electromagnetic reversing valve 4, first oil cylinder 5, safety valve 6, second electromagnetic reversing valve 7, pressure gauge 8, third electromagnetic reversing valve 9, first one-way speed regulating valve 10, second oil cylinder 11, first Two one-way speed control valve 12, the third one-way speed control valve 13, one-way sequence valve 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com