Weather resistance performance testing machine for external wall insulation system

A technology for external wall thermal insulation and detection machine, which is applied in the directions of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. The effect of testing flexibility, improving work efficiency and saving testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

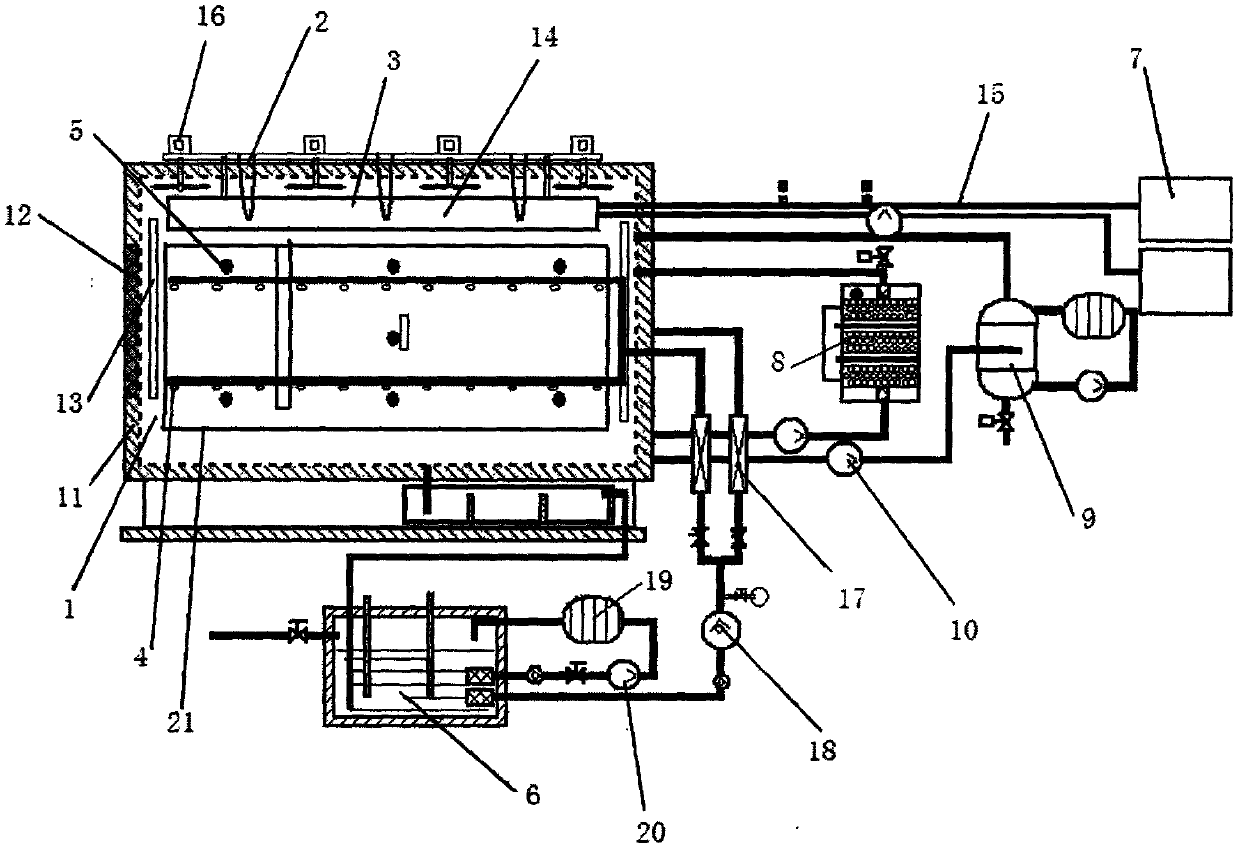

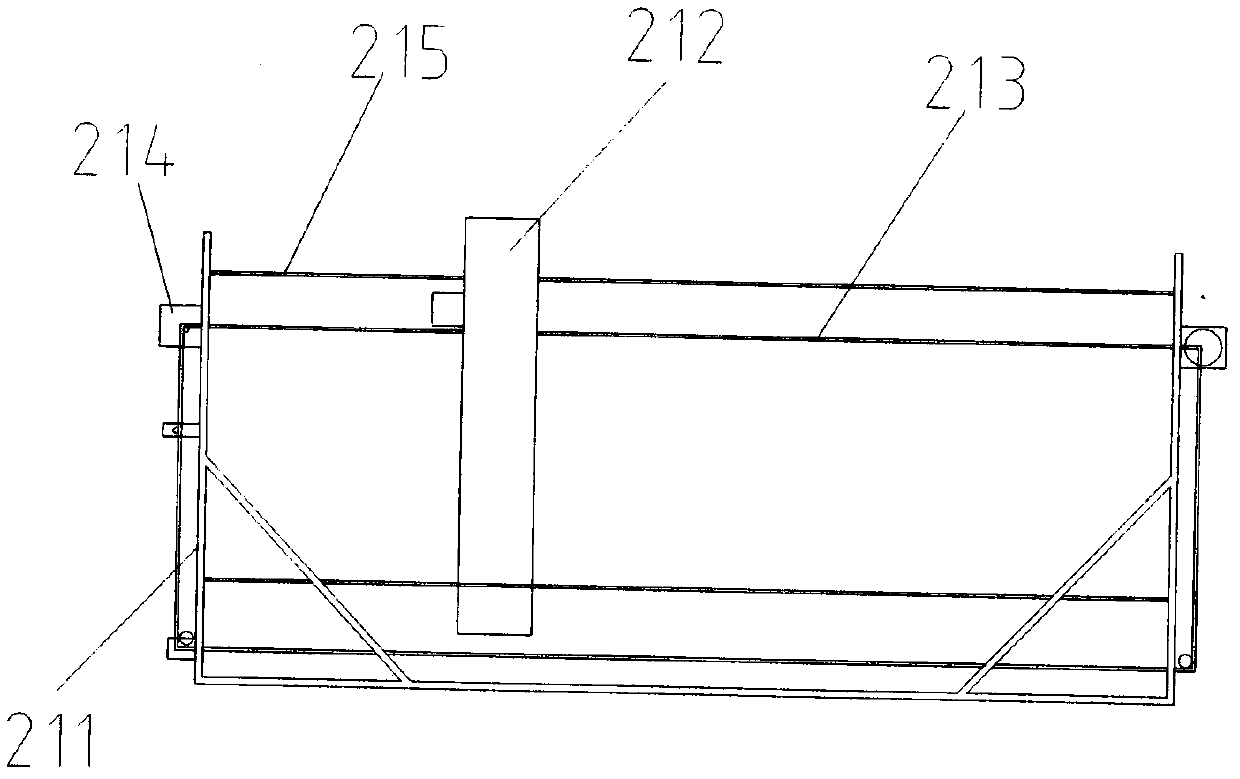

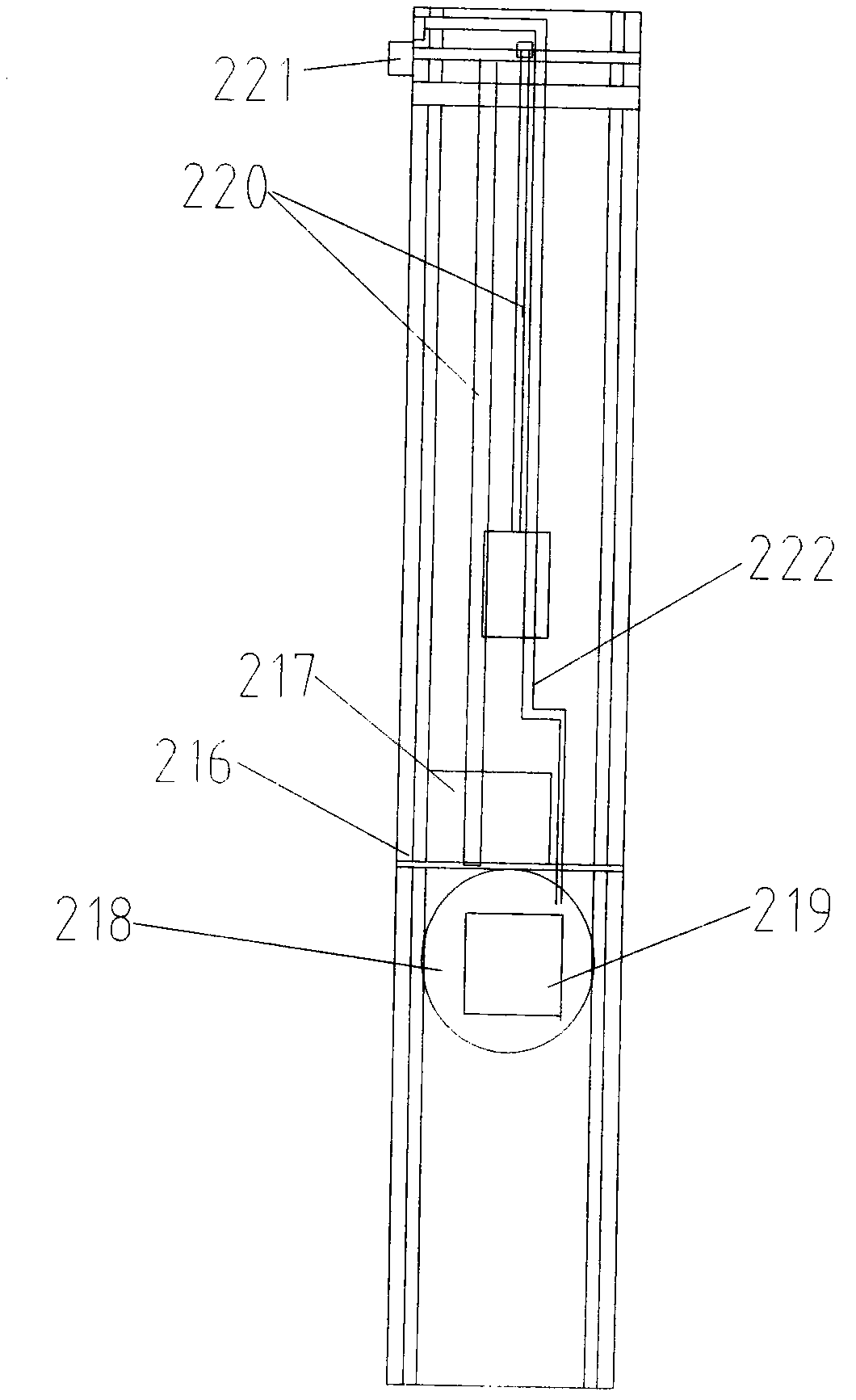

[0014] Such as Figure 1 to Figure 3 As shown, the weather resistance tester of the external wall insulation system of the present invention includes an instrument control system, a recording and electrical control system, an environmental box, a temperature and humidity measurement system, a dehumidification drying system, an air refrigeration system, an air heating system, and a circulating water cooling system. , water spray system; wherein the ring environment box 1 includes an environment box body 11, a heat preservation door 12, and an illumination device 13 is installed in the environment box 1; the temperature and humidity measurement system includes at least 16 platinum resistors 5 for measuring temperature and humidity; the dehumidification and drying system includes Drying box 8, moisture separator 9, dehumidification exhaust fan 10; air cooling system includes refrigeration unit 7, refrigeration pipeline 15, stainless steel air cooler 14; air heating system includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com