Sapphire glass cover plate and surface-mounted display employing same

A technology of sapphire glass and cover plate, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of reducing the outdoor readability of smart devices, reducing outdoor contrast, optimizing design, etc., to improve outdoor readability and reduce reflectivity , to improve the effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

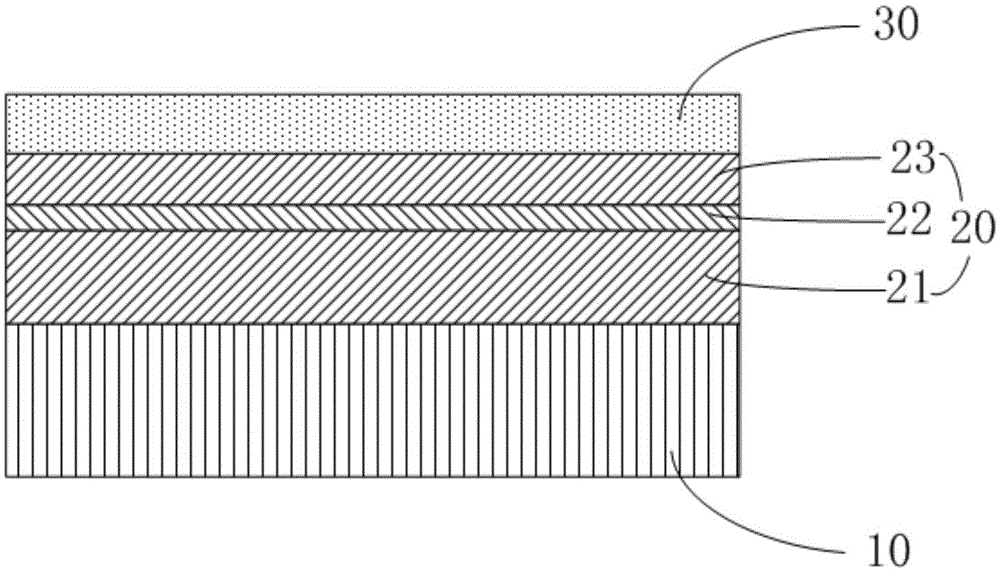

[0019] see figure 1 , is a schematic cross-sectional view of the sapphire glass cover plate (after the optical adhesive layer is bonded) in Example 1 of the present invention, the sapphire glass cover plate includes a sapphire glass substrate 10 and a coating film coated on the sapphire glass substrate 10 Layer 20.

[0020] In this example, see figure 1 , the optical glue layer 30 is covered on the coating layer 20 .

[0021] The coating layer 20 includes low-refractive index layers and high-refractive-index layers alternately stacked along its thickness direction; the layer closest to the sapphire glass substrate 10 is a low-refractive-index layer; the total layer of the low-refractive index layer and the high-refractive index layer The number is 2n or 2n+1 layers, wherein n is an integer greater than or equal to 1 and less than or equal to 5; the refractive index of the low refractive index layer is 1.5-1.6; the refractive index of the high refractive index layer is 1.75-2...

Embodiment 2

[0027] The basic structure of the sapphire glass cover plate of embodiment 2 is the same as embodiment 1, and the difference is that: the materials and thicknesses adopted in each layer of coating layer 20 are different, specifically as follows:

[0028] In embodiment 2, the coating layer 20 includes 3 layers (2n+1, and n=1), wherein, one layer closest to the sapphire glass substrate 10 is the low refractive index layer 21, and its material adopts Al 2 o 3 , the refractive index is about 1.54, and the thickness of this layer is 29nm; the middle layer is a high refractive index layer 22, its material is SiN, the refractive index is about 2.1, and the thickness of this layer is 10nm; the outermost layer is a low Refractive index layer 23, its material adopts Al 2 o 3 , the refractive index is about 1.54, and the thickness of the layer is 94nm.

Embodiment 3

[0030] The basic structure of the sapphire glass cover plate of embodiment 3 is the same as embodiment 1, and the difference is that: the materials and thicknesses adopted in each layer of coating layer 20 are different, specifically as follows:

[0031] In embodiment 3, the coating layer 20 includes 3 layers (2n+1, and n=1), wherein, one layer closest to the sapphire glass substrate 10 is the low refractive index layer 21, and its material adopts Al 2 o 3 , the refractive index is about 1.54, and the thickness of this layer is 29nm; the middle layer is a high refractive index layer 22, and its material is ZrO 2 , the refractive index is about 1.97, and the thickness of this layer is 12nm; the outermost layer is a low refractive index layer 23, and its material is Al 2 o 3 , the refractive index is about 1.54, and the thickness of this layer is 92nm.

[0032] The sapphire glass cover plate of the present invention can be applied to fully laminated displays.

[0033] Genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com