Light-weight shifting-type corn thresher

A threshing machine, corn technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problem of insufficient adjustment of the threshing gap, and achieve the effect of saving space, good stability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

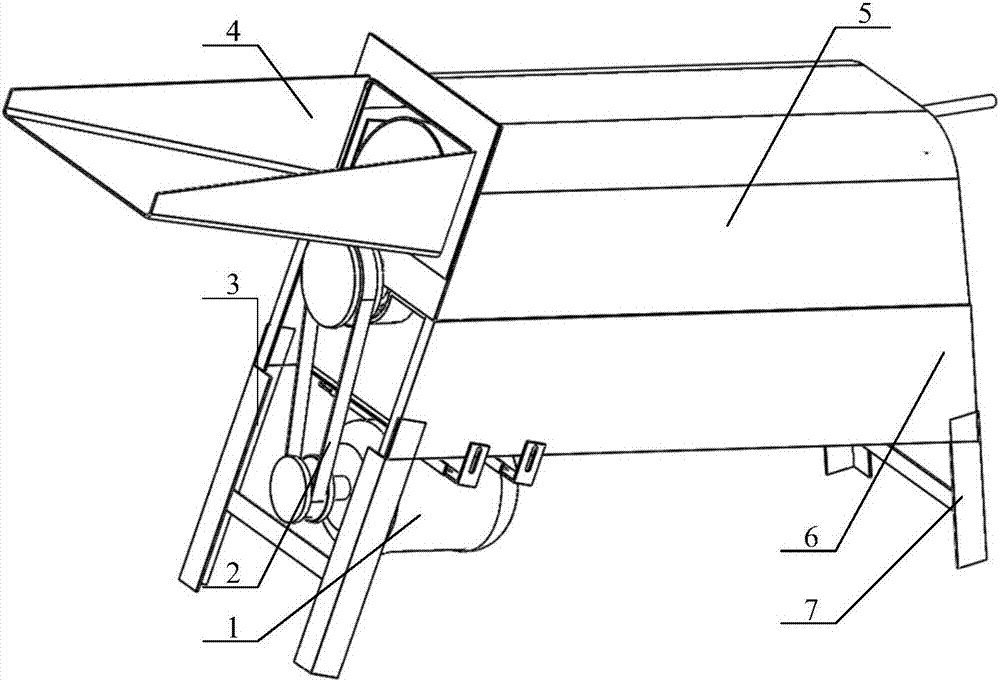

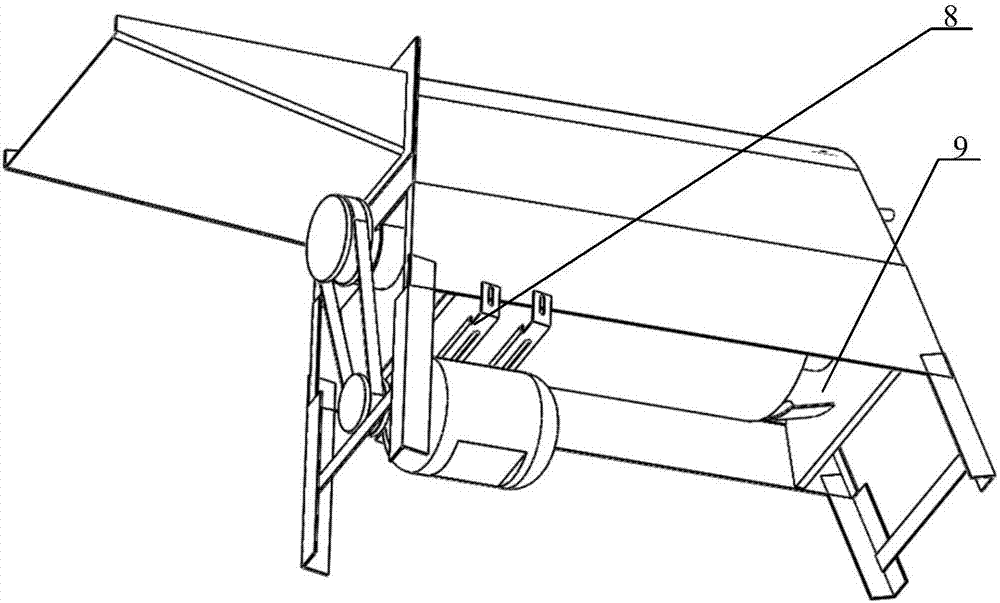

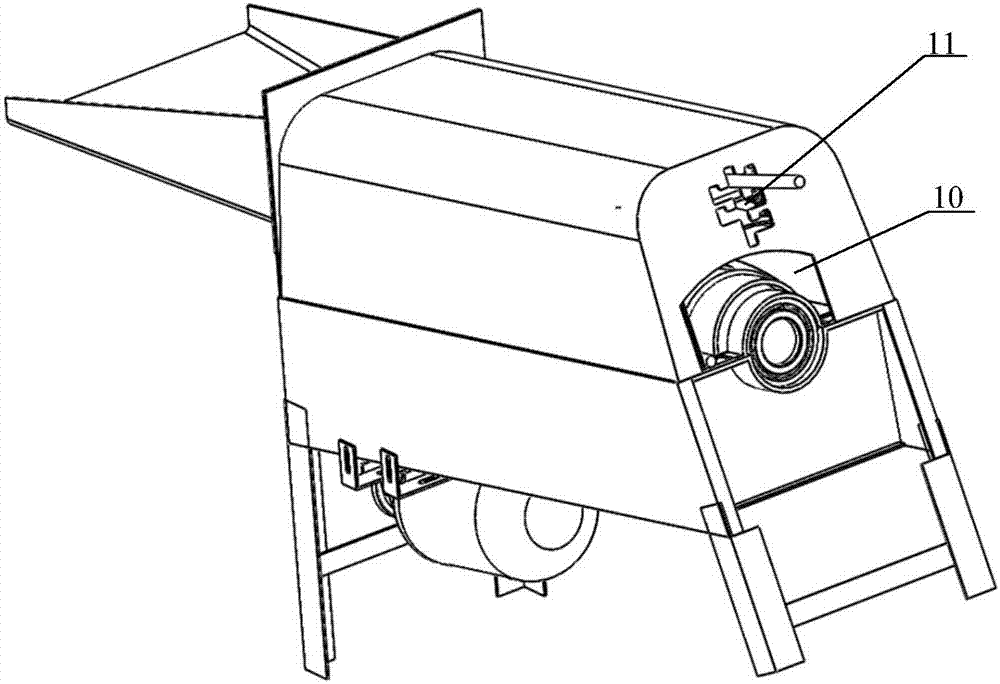

[0017] Such as figure 1 , figure 2 as well as image 3 As shown, a light shift type corn thresher includes: motor (1), belt (2), front legs (3), hopper (4), box cover (5), box body (6), rear Support legs (7), motor support (8), grain outlet (9), core outlet (10), shift device (11), threshing drum (12), and gland (13).

[0018] The motor (1) is fixed under the box (6) through the motor bracket (8), and is connected to the pulley on one side of the threshing drum (12) through the belt (2), and the two ends of the threshing drum (12) are fixed by rolling bearings and bearing seats On the box (6), such as Figure 4 As shown, both sides of the threshing drum (12) are welded with spiral threshing ribs (122). The cross section of the spiral threshing ribs (122) is circular, and the diameter of the circular section is 4~5mm. It is welded to the threshing drum according to the spiral shape. The surface of (12) has a pitch of 400~500mm, and a spiral feeding rib (121) is welded on the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com