Separable front dust removal tank of flue gas purification equipment

A technology of flue gas purification and dust removal box, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of waste of resources, difficulty in filter replacement, etc., and achieve the effect of easy cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

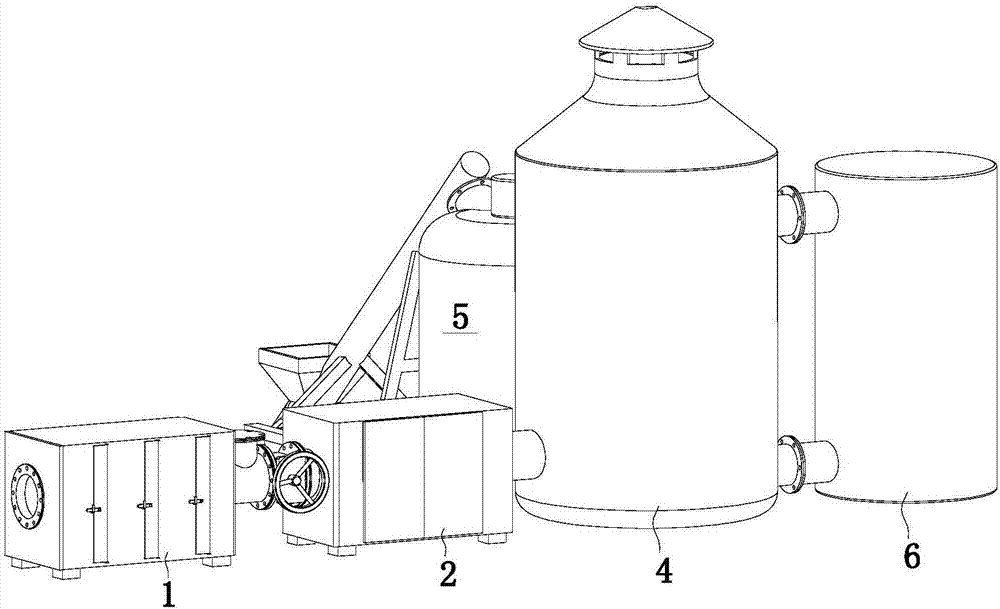

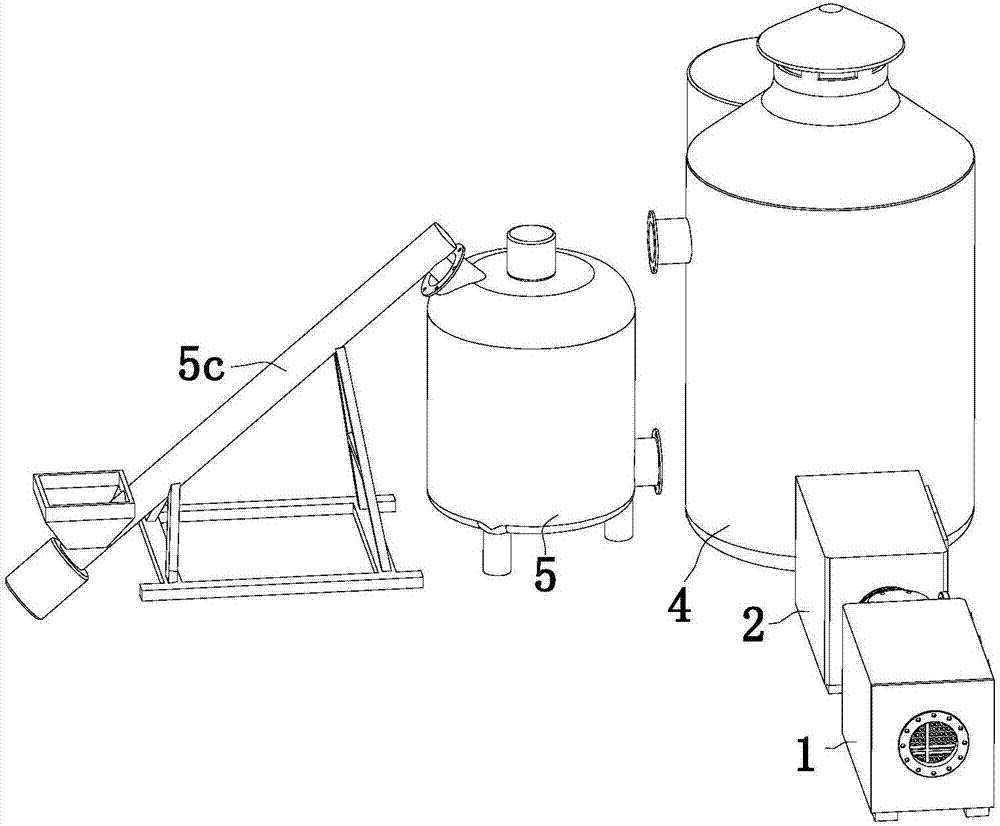

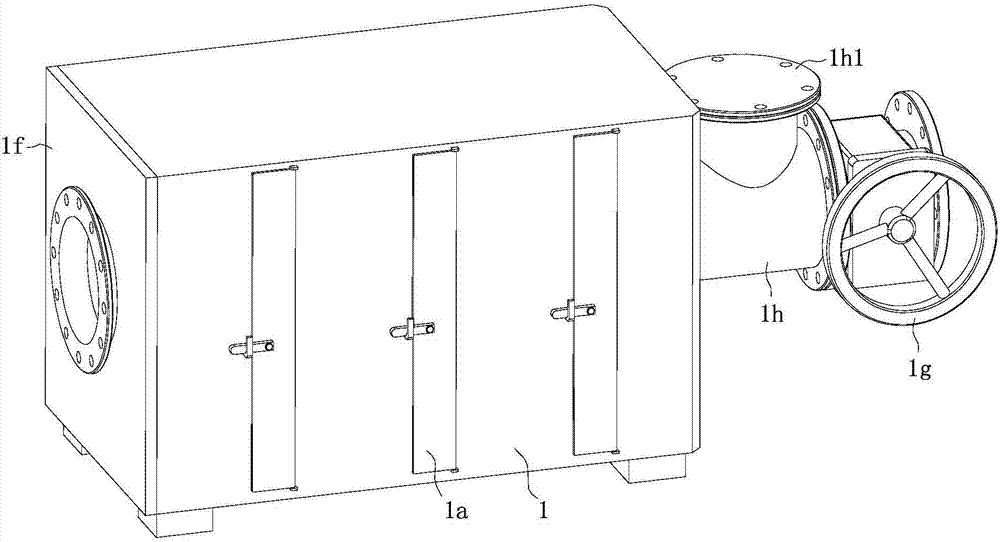

[0029] according to Figure 1 to Figure 11 The exhaust gas comprehensive treatment equipment shown includes a dust removal box 1, photocatalyst exhaust gas treatment equipment and desulfurization and denitrification equipment. The left and right ends of the dust removal box 1 are respectively provided with connecting flanges, and the dust removal box 1 extends the straight line connecting the flanges at both ends. There are multiple rows of activated carbon filters evenly distributed in the direction; the photocatalyst waste gas treatment equipment includes a box body 2, the two ends of the box body 2 are respectively provided with connecting flanges, the box body 2 and the dust removal box 1 are connected by pipelines, and the inner extension There are many rows of honeycomb panels distributed in the straight line ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com