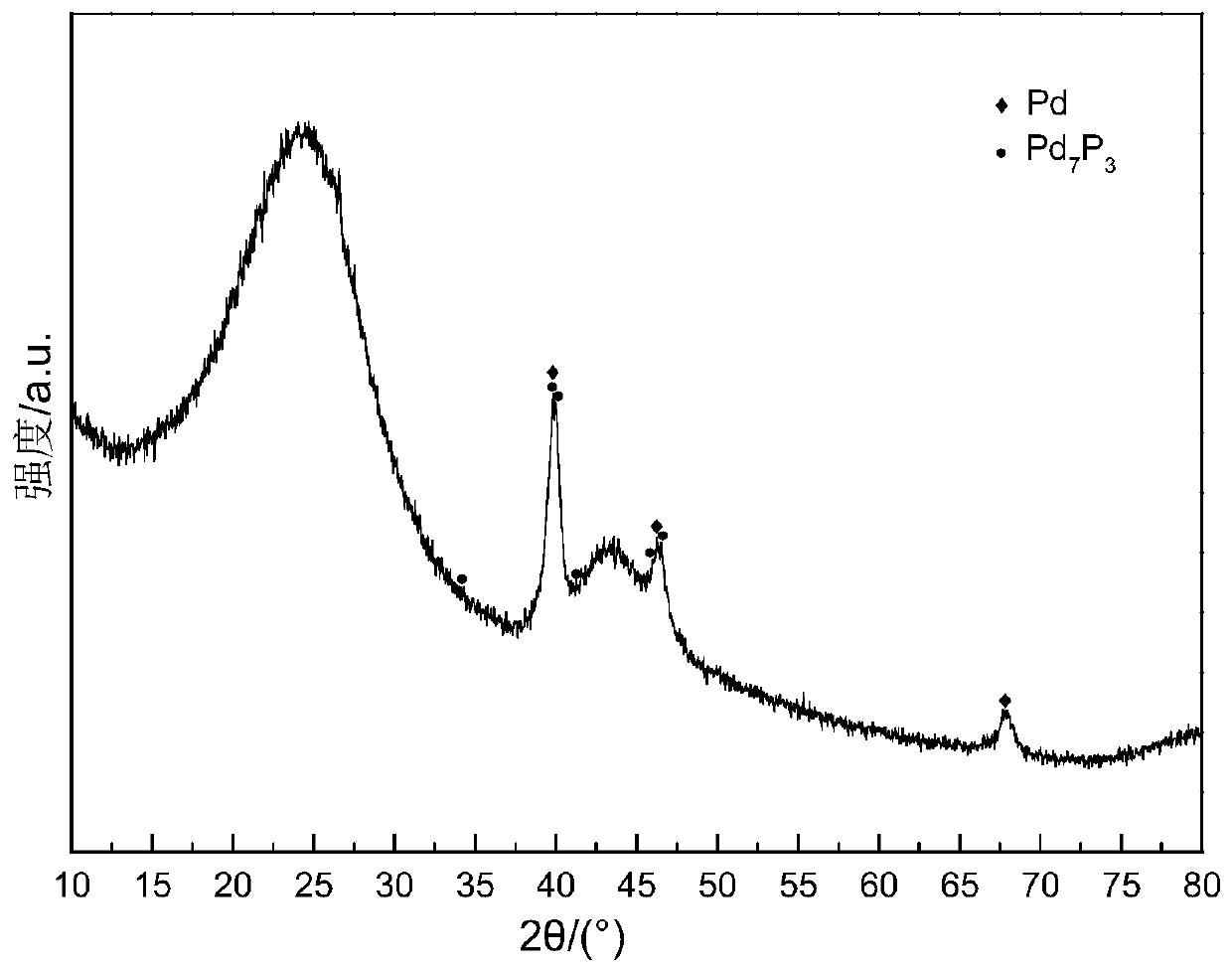

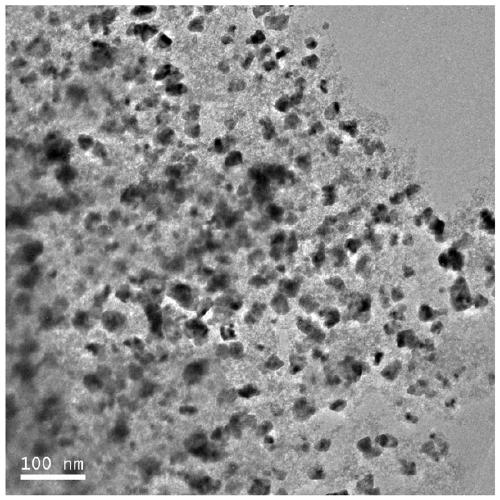

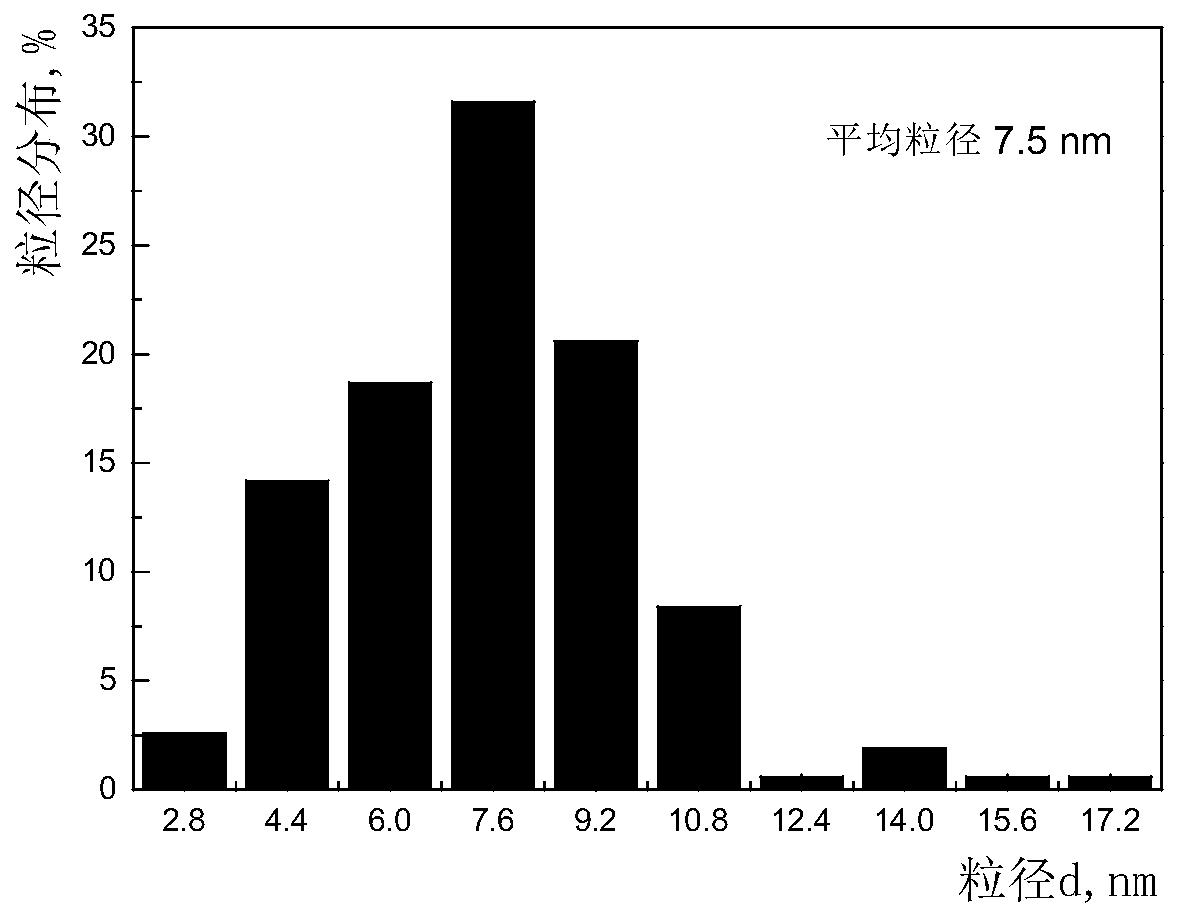

A kind of phosphorus-modified carbon-supported palladium catalyst and application thereof

A palladium catalyst and phosphorus modification technology, which is applied in the field of catalytic hydrogenation of halogenated aromatic nitro compounds to synthesize halogenated aromatic amines, can solve the problem of reducing the dispersion of active group components, reducing catalytic activity and reaction rate, and reducing the effective utilization of precious metals efficiency and other issues, to achieve the effects of inhibiting dehalogenation, improving product production efficiency and utilization of production equipment, and significant technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 17

[0049] The content, proportion and preparation conditions of the catalyst active components are provided (as shown in Table 1).

[0050] Catalyst concrete preparation process is as follows (taking embodiment 1 as example):

[0051] (a) Set the specific surface area to 1300m 2 / g, 0.80mL / g pore volume, 3.5% ash content coconut shell activated carbon, vacuum drying and dehydration at 110°C for 5h;

[0052] (b) Weigh 1.4194g of sodium hypophosphite solid (5wt% load) and add it to 30mL of ethylene glycol, stir until completely dissolved to obtain system A; then immerse 10g of activated carbon dried and dehydrated in step (a) in system A , after stirring evenly, let stand at room temperature for 2 days, and then dry at 120°C for 8 hours. Then put the sample in a quartz boat and place it in a tube furnace, replace the air and fill it with nitrogen, then raise the temperature to 350°C at a rate of 5°C / min in nitrogen, then keep the temperature at 350°C for 4 hours, Take out after ...

Embodiment 18

[0076] Add the phosphorus-modified carbon-supported palladium supported catalyst prepared by 200g p-chloronitrobenzene and 1.0g embodiment 1 in the 500mL autoclave, close the autoclave, replace the air in the reactor with nitrogen, then replace the nitrogen with hydrogen, Start the stirring, the stirring speed is 1200r / min, the reaction temperature is maintained at 90°C, and the hydrogen pressure is 1.0MPa to carry out the reaction. When the content of p-chloronitrobenzene was detected to be 0 by chromatography, the reaction was stopped and the catalyst was filtered. The filtrate is the product after phase separation, water separation and dehydration by vacuum distillation. Quantitative analysis (molar percentage) by chromatography shows that the conversion rate of hydrogenation reaction is 100%, and the selectivity is 99.99%.

[0077] The operating condition of embodiment 19~embodiment 36 is the same as embodiment 18, is respectively the hydrogenation catalyst that the embodi...

Embodiment 55

[0090] Add the phosphorus-modified carbon-supported palladium supported catalyst prepared by 200g 6-chloro-2-nitrotoluene and 1.0g embodiment 1 in the 500mL autoclave, close the reactor, replace the air in the reactor with nitrogen, and then use The nitrogen gas was replaced by hydrogen, the stirring was started, the stirring speed was 1200r / min, the reaction temperature was maintained at 50°C, and the hydrogen pressure was 0.5MPa for the reaction. When the content of 6-chloro-2-nitrotoluene was detected to be 0 by chromatography, the reaction was stopped and the catalyst was filtered. The filtrate is the product after phase separation, water separation and dehydration by vacuum distillation. Quantitative analysis (molar percentage) by chromatography shows that the conversion rate of hydrogenation reaction is 100%, and the selectivity is 99.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com