Device and method for quickly connecting broken steel strips in a hanging solidification furnace

A curing furnace and hanging technology, which is applied in the direction of tensioning wire rods, manufacturing tools, etc., can solve the problems affecting production efficiency and economic benefits, and achieve the effects of good popularization and use value, significant economic benefits, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

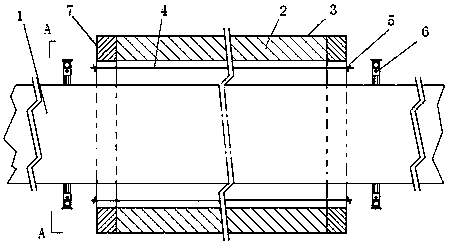

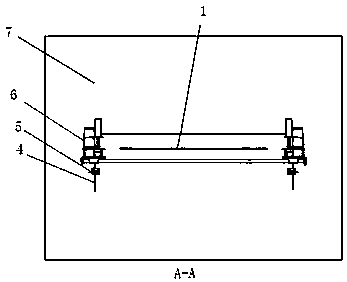

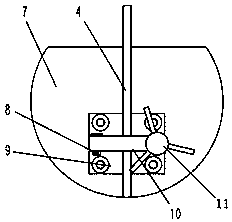

[0030] The broken steel strip fast connecting device in the hanging solidification furnace of the present invention is composed of a steel strand 4 , a steel strand joint fixing frame 5 , and a broken steel strip punching device 6 .

[0031] figure 1 , 2 It shows that there are two steel strands 4, and the two steel strands 4 are respectively pre-buried in the suspension curing furnace, and the two steel strands 4 are respectively located on both sides of the steel strip 1, and the two ends of the two steel strands 4 are respectively Protrude from both ends of the overhanging curing oven. The steel strand 4 adopts a material that can withstand the atmosphere in the furnace for a long time, and can withstand a certain tension of the strip. The pre-embedded locking position of the steel strand 4 should be able to avoid the steel strand 4 from being touched by the shaking of the steel strip 1 during the production process.

[0032] figure 1 , 2 It shows that there are four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com