Wood-plastic material, aluminum-clad wood-plastic door and window and preparation method thereof

A wood-plastic material and aluminum-clad wood technology, which is applied to wood-plastic materials and their application fields, can solve the problems of easy deformation and insufficient strength of doors and windows, and achieve the effect of high mechanical strength and not easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

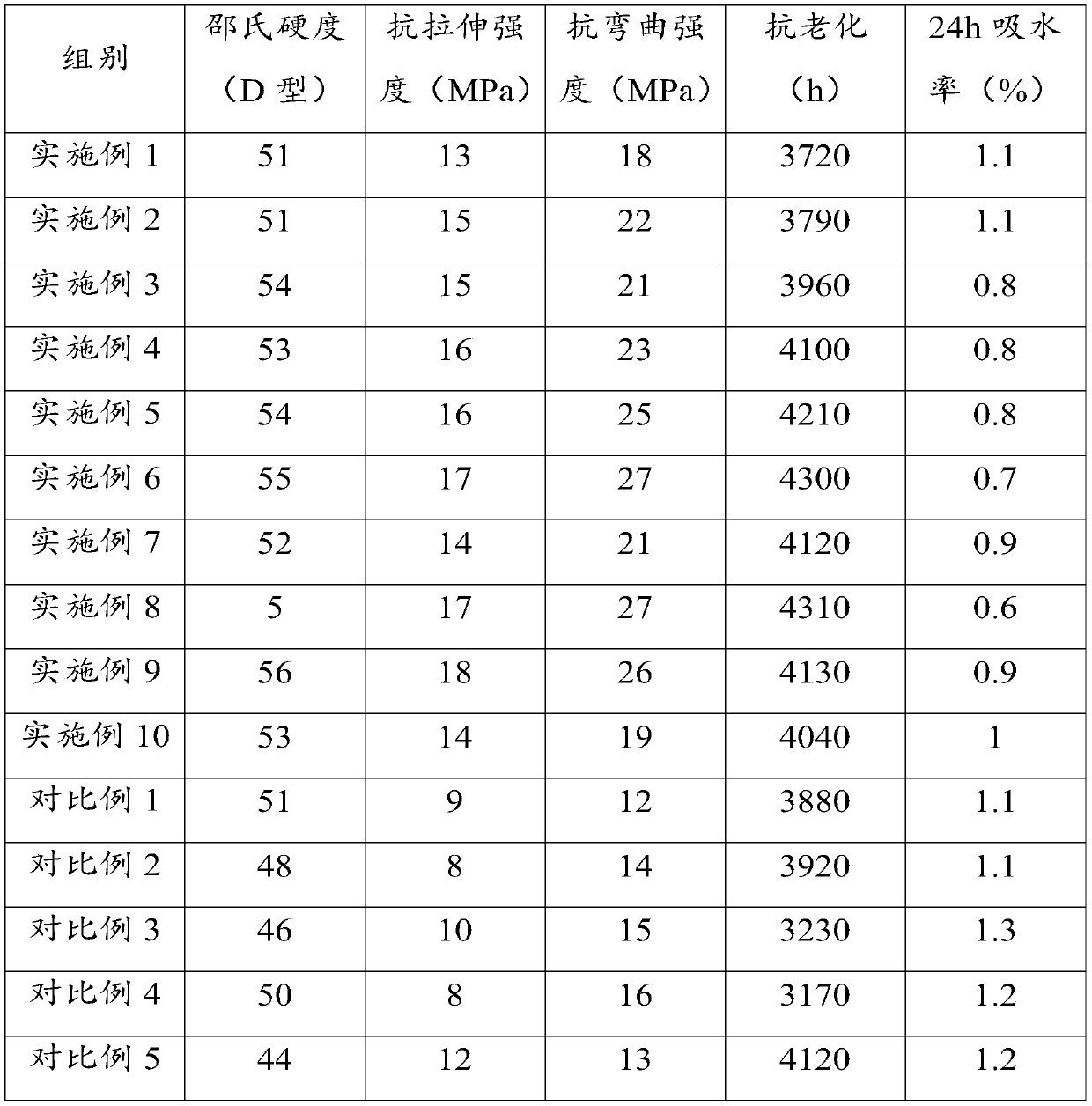

Examples

preparation example Construction

[0057] In a second aspect, the present invention provides a method for preparing a wood-plastic material, comprising the following steps: weighing each raw material in a formula amount, and then raising the temperature of resin, wood powder, rice husk powder, particle reinforcing agent and fiber reinforcing agent and stirring once, and finally adding the rest of the raw materials for second heating and second stirring to obtain the wood-plastic material. The above preparation method is simple and easy, and the produced wood-plastic material has the advantage of high strength.

[0058] In a preferred embodiment, the temperature is raised to 70-90°C once;

[0059] Preferably, the speed of a stirring is 150-500r / min;

[0060] Preferably, the temperature is raised to 90-120°C for the second time;

[0061] Preferably, the speed of secondary stirring is 700-1200r / min.

[0062] The formulation of the above parameters has fully considered the physical and chemical properties of eac...

Embodiment 1

[0067] A wood-plastic material, comprising the following raw materials in parts by weight: 35 parts by weight of PVC resin, 50 parts by weight of ash wood powder, 15 parts by weight of rice husk powder, 3 parts of aluminum oxide, 4 parts of carbon fiber, dibasic phthalic acid 2 parts of lead, 0.5 part of dioctyl phthalate, 2 parts of titanate coupling agent and 0.2 part of anti-aging agent.

Embodiment 2

[0080]A wood-plastic material, comprising the following raw materials in parts by weight: 35 parts by weight of PVC resin, 50 parts by weight of ash wood powder, 15 parts by weight of rice husk powder, 3 parts of aluminum oxide, 6 parts of carbon fiber, dibasic phthalic acid 2 parts of lead, 0.5 part of dioctyl phthalate, 2 parts of titanate coupling agent and 0.2 part of anti-aging agent.

[0081] The difference from Example 1 is that the weight ratios of alumina and carbon fibers are different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com