Stage continuous fermentation cylinder set

A fermentation tank and stage-based technology, applied in the field of stage-type continuous fermentation tanks, can solve problems such as product impact, inconsistent fermentation conditions, and prone to problems, and achieve high utilization rate and consistent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

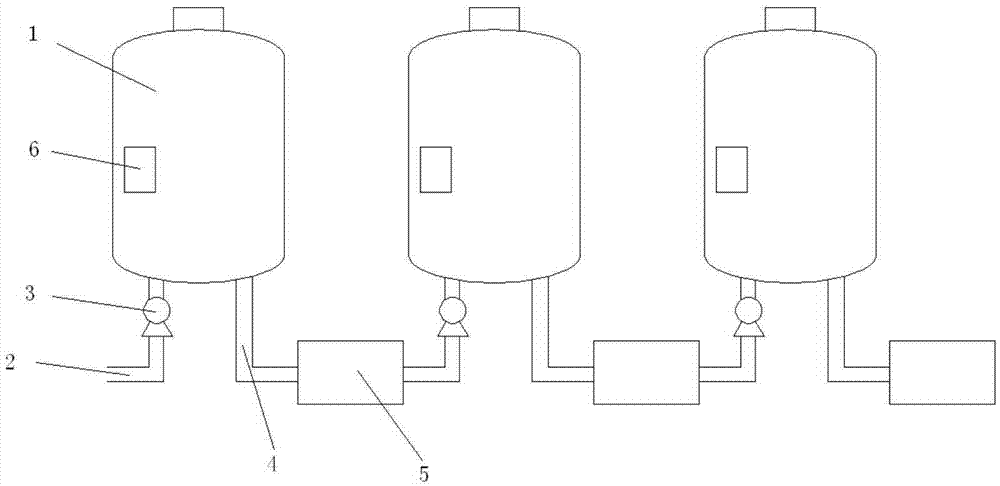

[0014] Such as figure 1 As shown, the present invention relates to a staged continuous fermentation tank group, comprising no less than two split fermentation tanks, the split fermentation tanks include a tank body 1, a feed pipe 2, a discharge pipe 4 and a sedimentation filter tank 5, and the feed There is a feed pump 3 on the pipe 2, a feed port is provided at the bottom of the tank body 1, the feed pipe 2 is connected to the feed port through a feed valve, the feed valve controls the switch of the feed port, and a discharge port is provided at the bottom of the tank body. The discharge port is connected to the discharge pipe 4, the discharge port is provided with a discharge valve, the discharge valve controls the switch of the discharge port, the downstream of the discharge pipe 4 is provided with a sedimentation filter tank 5, and the fermented liquid ent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap