A carding machine control device

A technology for control devices and carding machines, applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve problems such as high product failure rate, pipeline blockage, and affecting production efficiency, so as to improve automation and reduce pipelines The frequency of clogging, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

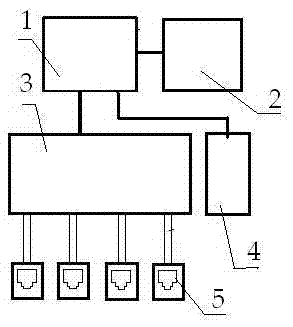

[0011] Referring to the drawings, the present invention includes a central controller 1, a carding machine interface device 2, an information interface device 3, a blower fan 4 and a sensor group 5, and the central controller 1 communicates with the carding machine interface device 2 respectively through signal lines. It is connected with the information interface device 3, the central controller 1 is connected with the fan 4 through the control line, and the information interface device 3 is connected with the sensor group 5 through the signal line. Carding machine interface device 2 is provided with a carding machine starting module and a cotton feeding machine frequency conversion module. Sensor group 5 includes sound and light alarm sensors, pressure sensors and fault signal sensors. The working principle is: after the carding machine is started, the central controller 1 receives a signal through the carding machine starting module. The frequency conversion module of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com