4A2 diesel engine body

A diesel engine and body technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as the inability to guarantee the reliable operation life of the diesel engine, the limitation of the oil inlet rate of the body temperature, insufficient stiffness and strength, etc., and achieve the improvement of speed and Body performance, not easy to vortex and air resistance, improve the effect of connection rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

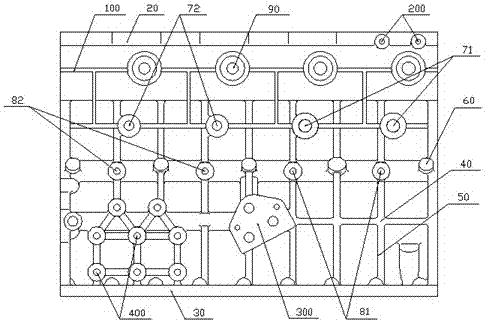

[0020] Such as figure 1 As shown, it is a 4A2 diesel engine body according to the present invention, including a body body 10, a cover plate 20 is provided at the top of the body body 10, and a reinforcing plate 30 is provided at the bottom end of the body body 10;

[0021] The machine body 10 is provided with transverse reinforcing ribs 40 and longitudinal reinforcing ribs 50, and the transverse reinforcing ribs 40 and longitudinal reinforcing ribs 50 are vertically staggered;

[0022] The inside of the body 10 is processed with an oil channel 60 for delivering lubricating oil to each moving part. The front end of the body 10 is provided with a primary oil pump oil inlet 71 and a secondary oil pump oil inlet connected to the diesel engine oil pump. 72, and the oil outlet hole 81 of the corresponding primary oil pump and the oil outlet hole 82 of the secondary oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com