Inner heat dissipation device of spectrometer

A heat dissipation device and spectrometer technology, applied in the direction of measuring devices, instruments, spectrometry/spectrophotometry/monochromator, etc., can solve the problems of complex internal structure and high cost of cooling fans, and achieve heat dissipation effect, transfer The effect of stable and reliable wheel structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

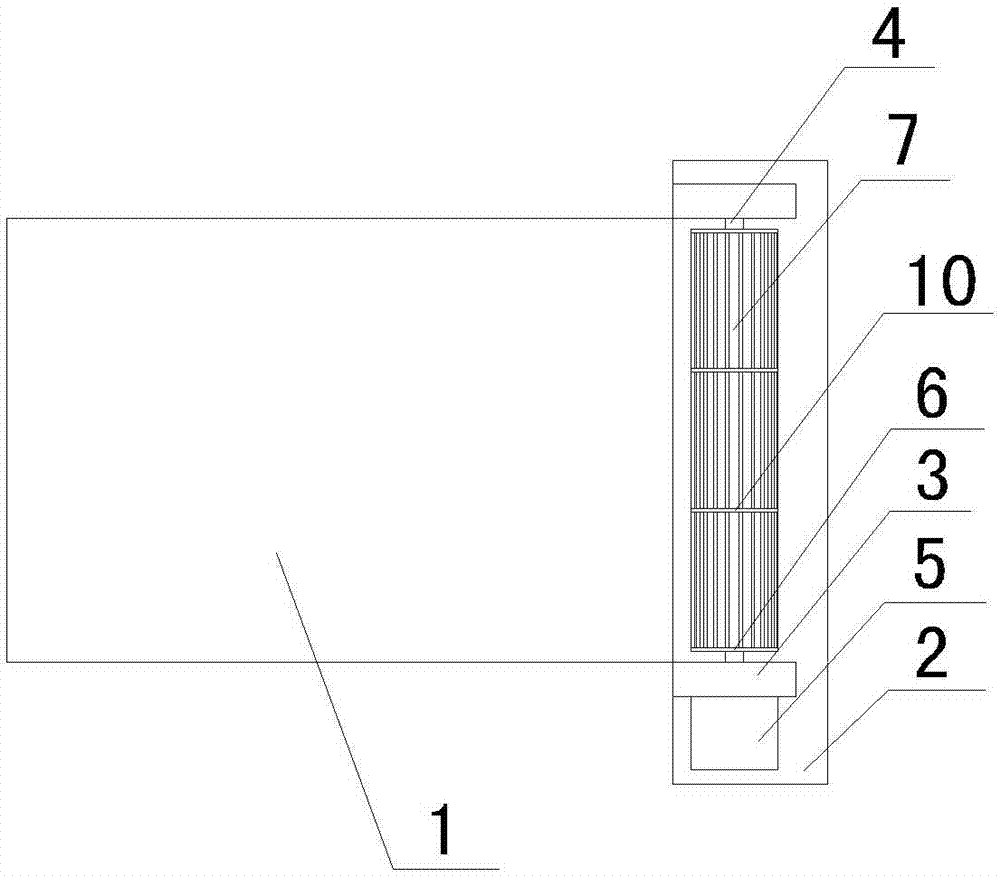

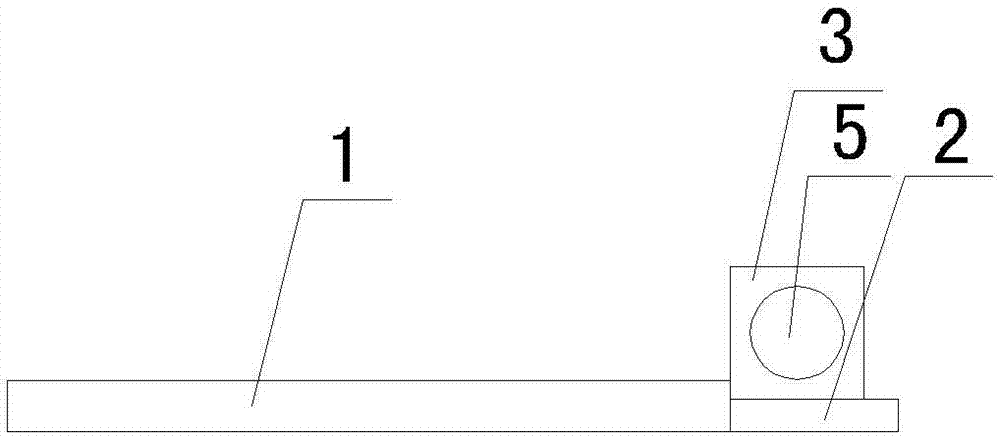

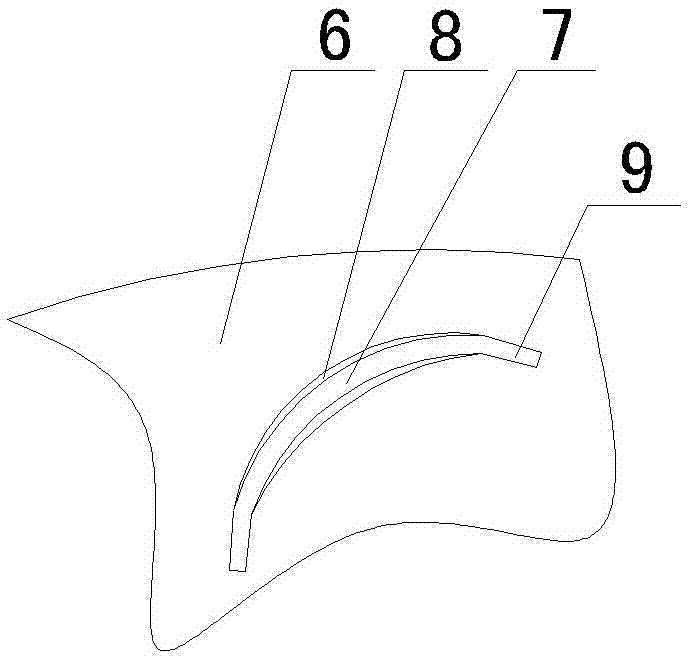

[0012] See figure 1 , figure 2 , image 3 As shown, a heat dissipation device in a spectrometer includes an electronic device mounting plate 1, a heat dissipation base 2 is installed on one side of the electronic device mounting plate 1, support bases 3 are installed at both ends of the heat dissipation base 2, and two support bases 3 pass through The rotating shaft 4 is equipped with a running wheel device, and one end of the rotating shaft 4 is connected to the drive motor 5. The rotating wheel device includes a disc 6 on both sides and a plurality of strip blades 7 installed on the disc 6, and the strip blades 7 are along the circumferential direction of the disc. Evenly arranged, the cross section of the strip blade 7 is arc-shaped, the central angle of the cross section of the strip blade is 90° to 120°, and the length of the strip blade 7 corresponds to the size of the electronic device mounting board 1, ensuring that the entire electronic device mounting board 1 is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com