Method for predicting service life of hydraulic asphalt concrete

A technology of asphalt concrete and operating life, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as difficulty in predicting the life of hydraulic asphalt concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

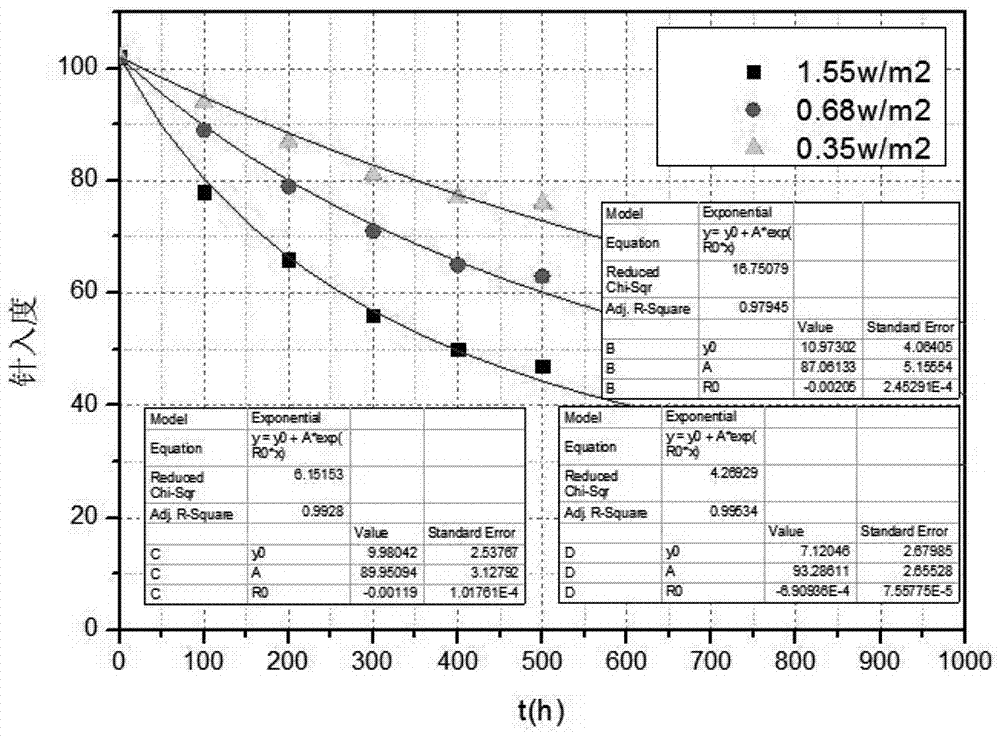

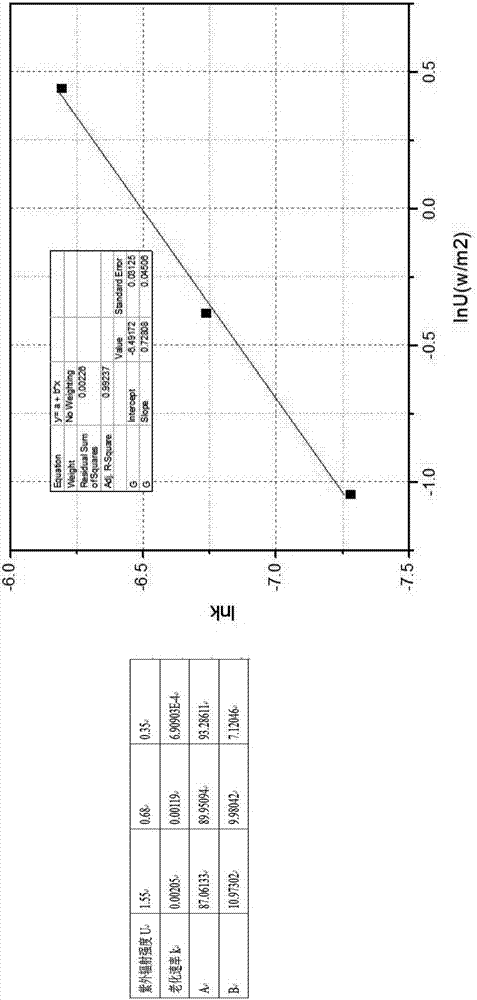

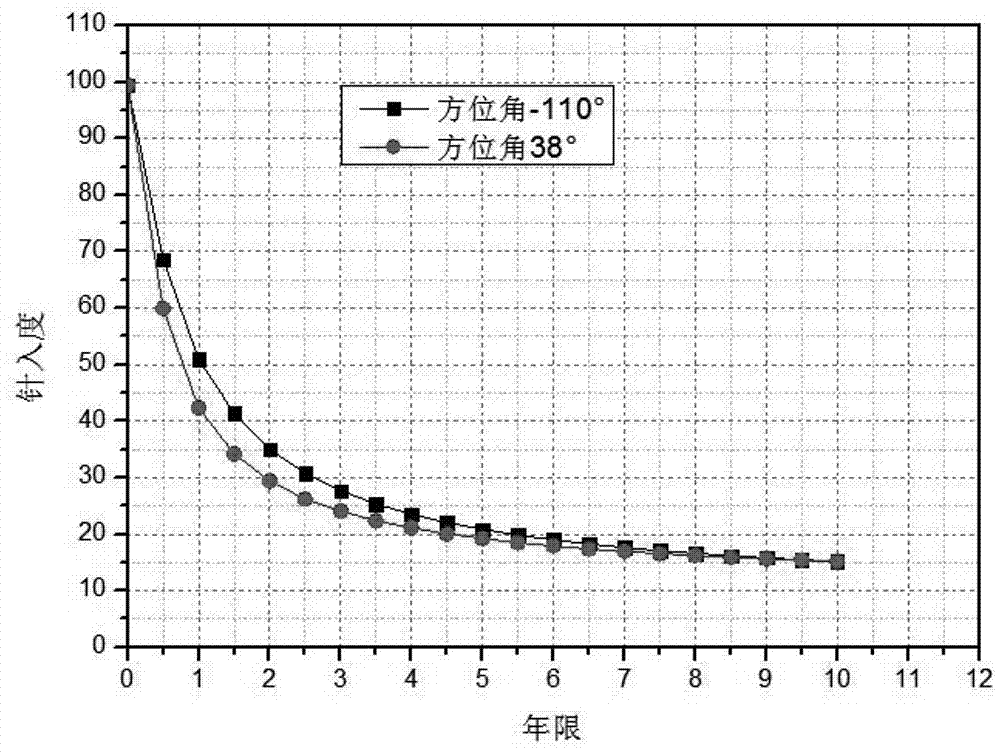

[0025] In this embodiment, the aging formula is deduced after on-site sampling and aging test, and the service life of the hydraulic asphalt concrete is predicted by combining the aging formula with the performance characteristics of the hydraulic asphalt concrete and the actual project operation conditions.

[0026] The derivation steps of the aging formula in this embodiment are as follows:

[0027] a. On-site coring: For hydraulic asphalt concrete anti-seepage projects, in order to deeply study and predict the life of asphalt concrete, it is necessary to take on-site coring. According to the operating life and performance status of asphalt concrete, study the current properties of asphalt concrete, Then the service life of asphalt concrete can be deduced according to its running time.

[0028] In order to make the research results closer to the actual operation, the on-site coring process should be carried out in different areas. Since the life of hydraulic asphalt concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com