A frequency converter maintenance test system

A test system and frequency converter technology, applied in instruments, measuring electrical variables, measuring devices, etc., can solve the problems of inability to test large current loads, various voltage levels of frequency converters, difficulty in obtaining control power, etc., and achieve convenient circuit wiring and debugging. The circuit is stable and the energy consumption is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

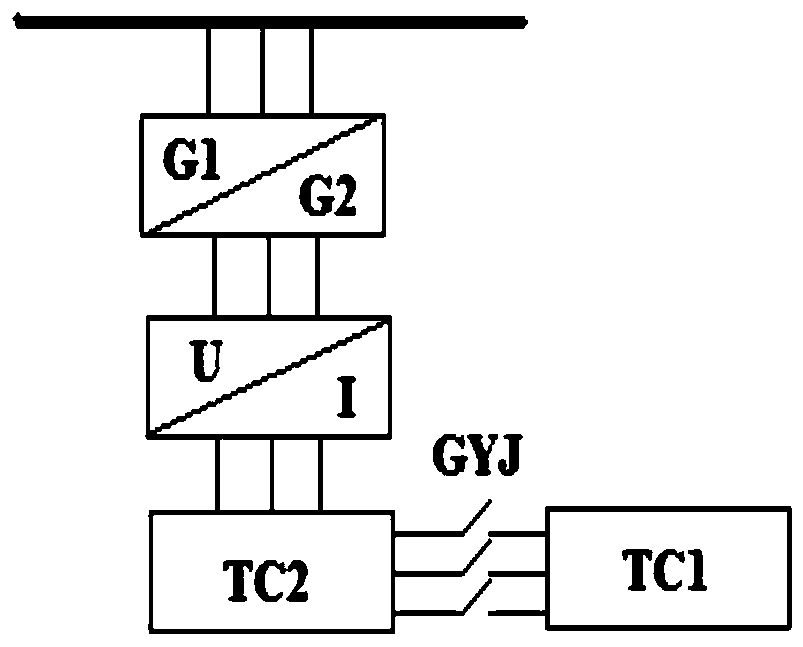

[0033] like figure 1 Shown is the test structure diagram of Embodiment 1 of the inverter maintenance test system of the present invention. The embodiment includes the inverter test control cabinet G1, the inverter test control cabinet G2, the tested inverter U, and the tested high-power inverter without rectification unit inverter system I, dry-type transformer TC1, and dry-type transformer TC2. This embodiment is suitable for low-voltage inverters and high-power inverters without rectification units. U can be a frequency converter of high power level, or a frequency converter of small and medium power level, which can be adjusted through the frequency converter test control cabinet G1.

[0034] When the tested inverter drives a large load test, the inverter test control cabinet G1 works, and the dry-type transformers TC1 and TC2 are connected to the circuit through the contactor GYJ controlled by the inverter test control cabinet G1. At this time, adjust the tested inverter f...

Embodiment 2

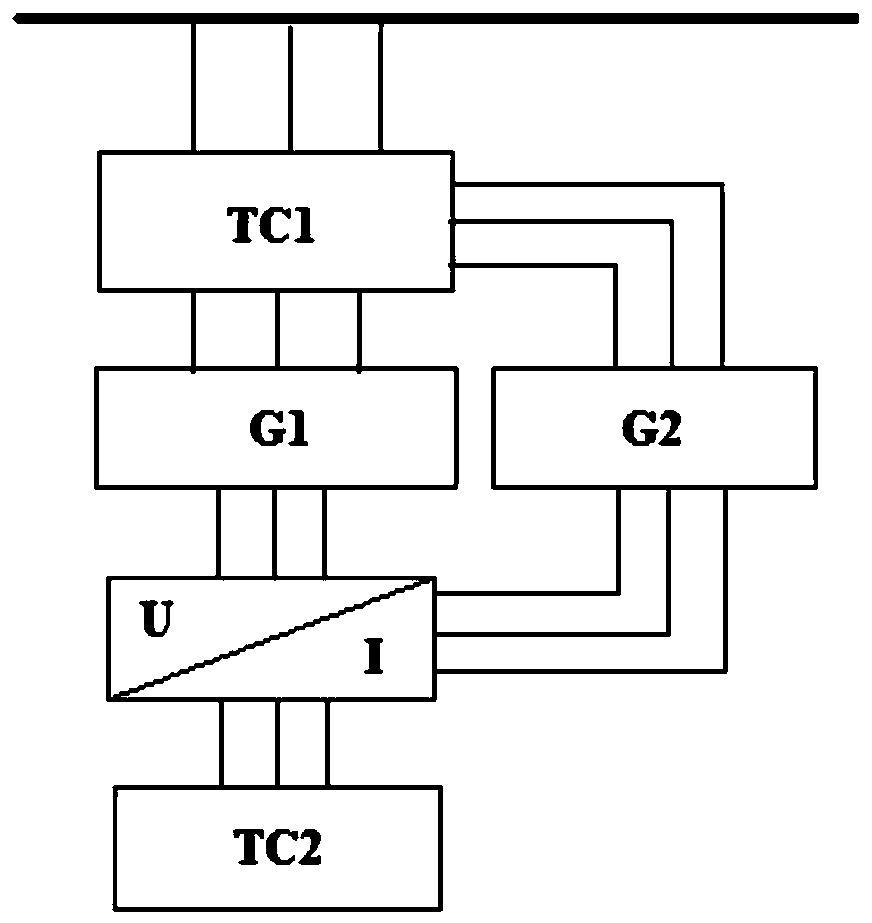

[0037] like figure 2 As shown, it is the test structure diagram of Embodiment 2 of the inverter maintenance test system of the present invention. The structure has been changed on the basis of Embodiment 1. This embodiment is suitable for inverters of medium and high voltage inverters and high voltage DC bus inverters without rectification units. Drive heavy load or no-load test after system maintenance.

[0038] By controlling the middle tap of the dry-type transformer TC1, using the principle of self-coupling, it can output 690V AC voltage. After the inverter test control cabinet G1 can test the 690V input voltage of the inverter under test, by adjusting the high-voltage side circuit of the dry-type transformer TC2 State, realize no-load and high-current load test. Through the frequency conversion test cabinet G2, the DC output of 550-1000V can be realized, providing power for the inverter system of the high-voltage DC bus inverter without rectification unit, and through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com