Turntable-type wafer automatic dividing loader

A loader and turntable technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of low labor efficiency, wafer misplacement in slot, product loss, etc., to reduce wafer loss. The effect of reducing the risk of work, reducing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but it does not mean limiting the protection scope of the present invention.

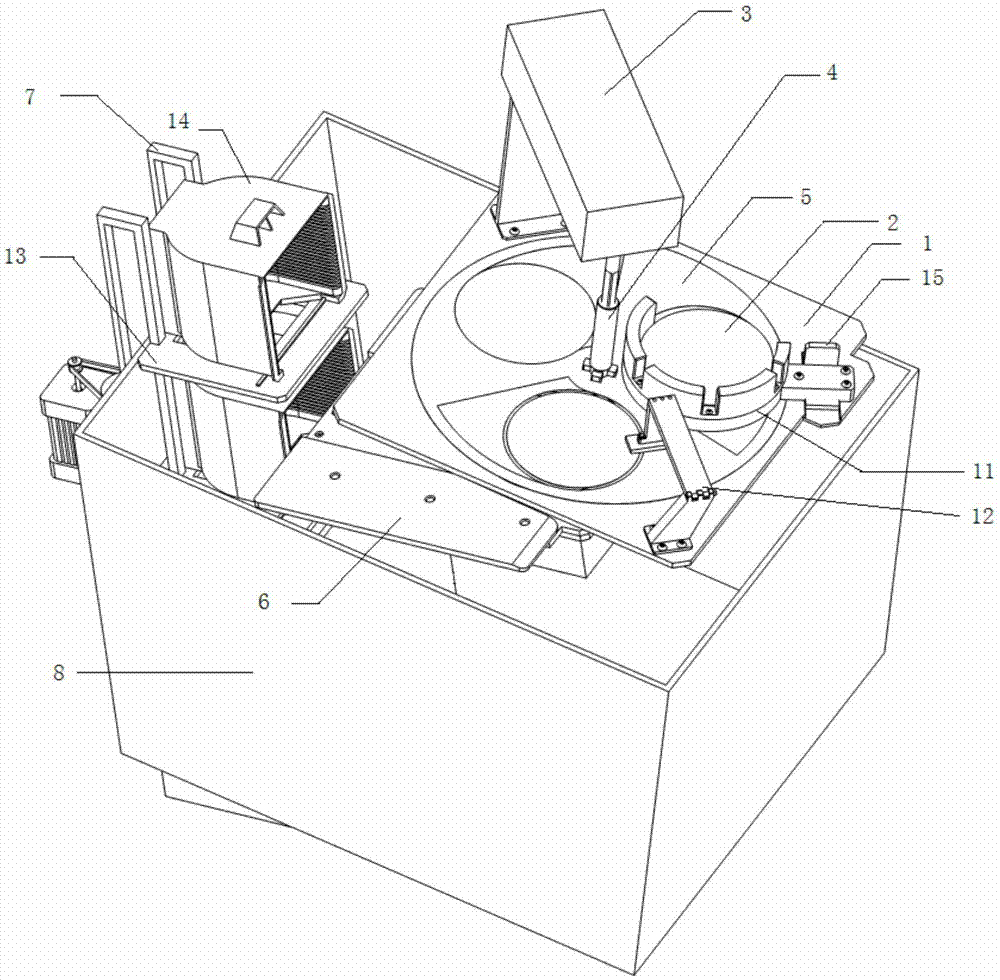

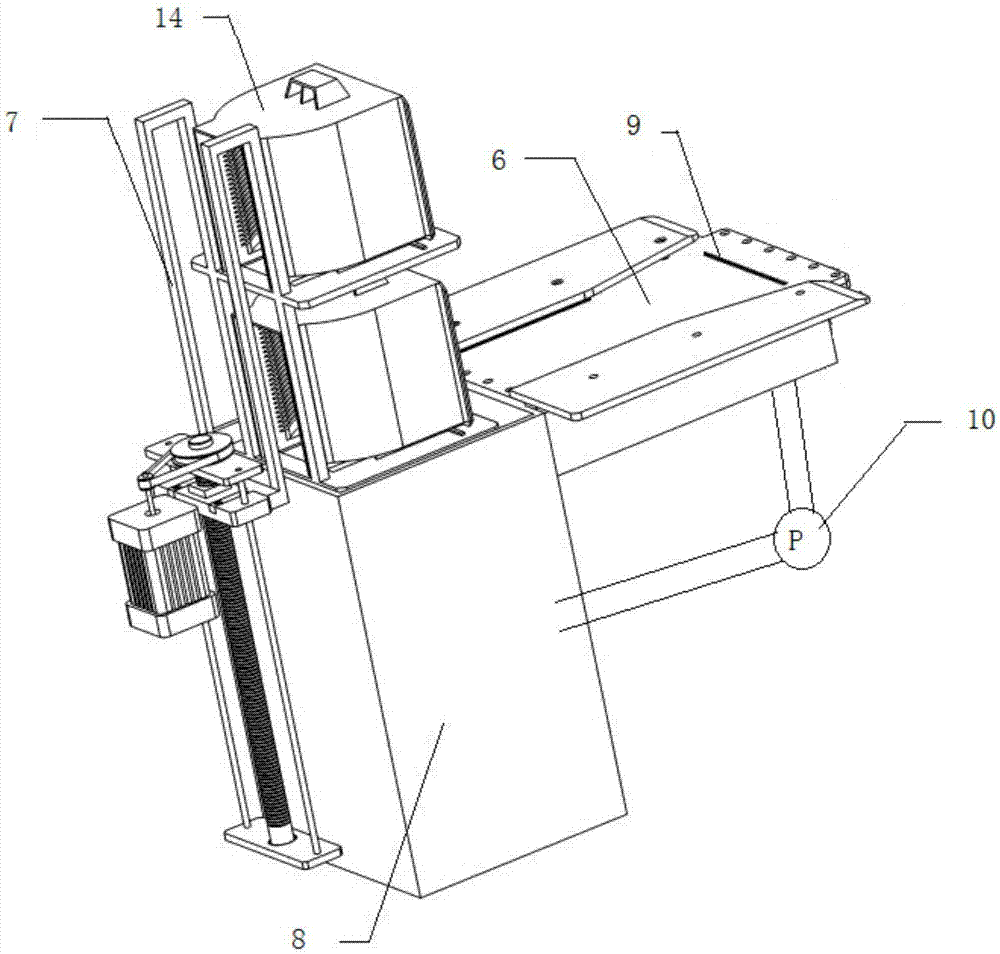

[0015] As shown in the figure, the turntable wafer automatic slicing loader includes a host platform 1, a loading table 2, a driving mechanism 3, a transmission rod 4, a slicing carrier 5, a slide ramp 6, a carrier lifting mechanism 7, Wafer carrier 14 and wafer carrier storage tank 8 . Wherein, the host platform 1 has leaking holes; the slice carrier 5 is arranged on the host platform 1, and is connected with the drive mechanism 3 through the transmission rod 4; the slice carrier 5 has a round hole for accommodating the wafer; the loading table 2 is located above the host platform near the edge; the driving mechanism 3 is located above the middle of the host platform 1; the upper end of the slide ramp 6 is located below the chip hole of the host platform 1, and the lower end is aligned with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com