Harvesting machine of sugar beets and carrots

A carrot and harvester technology, which is applied to excavating harvesters, harvesters, and topping machines, can solve the problems of high labor intensity for removing stems and leaves and digging roots, difficult to popularize and use, and single operation of machines and tools. Flexible, widely used, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

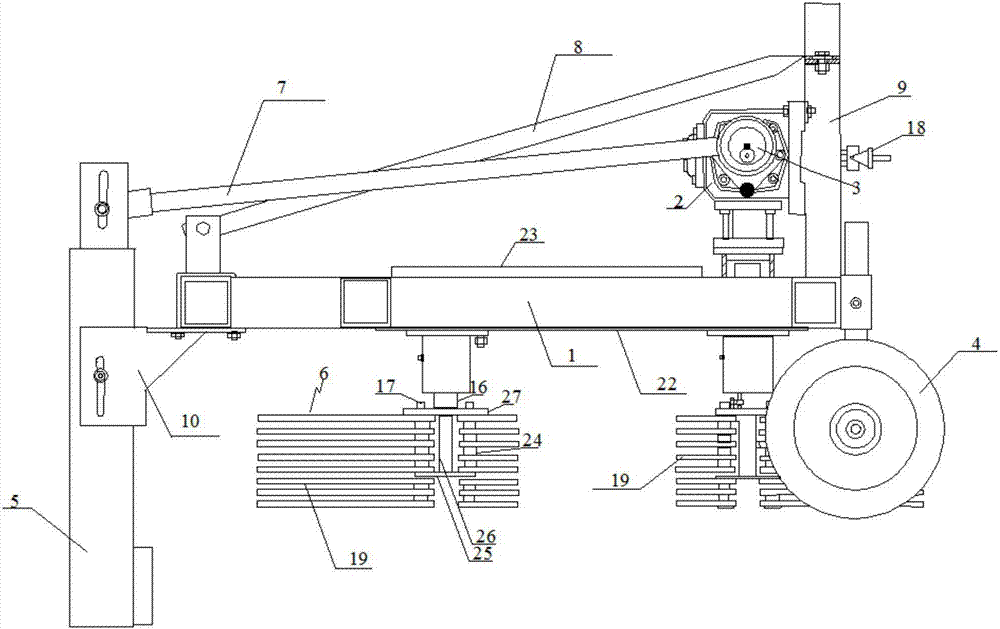

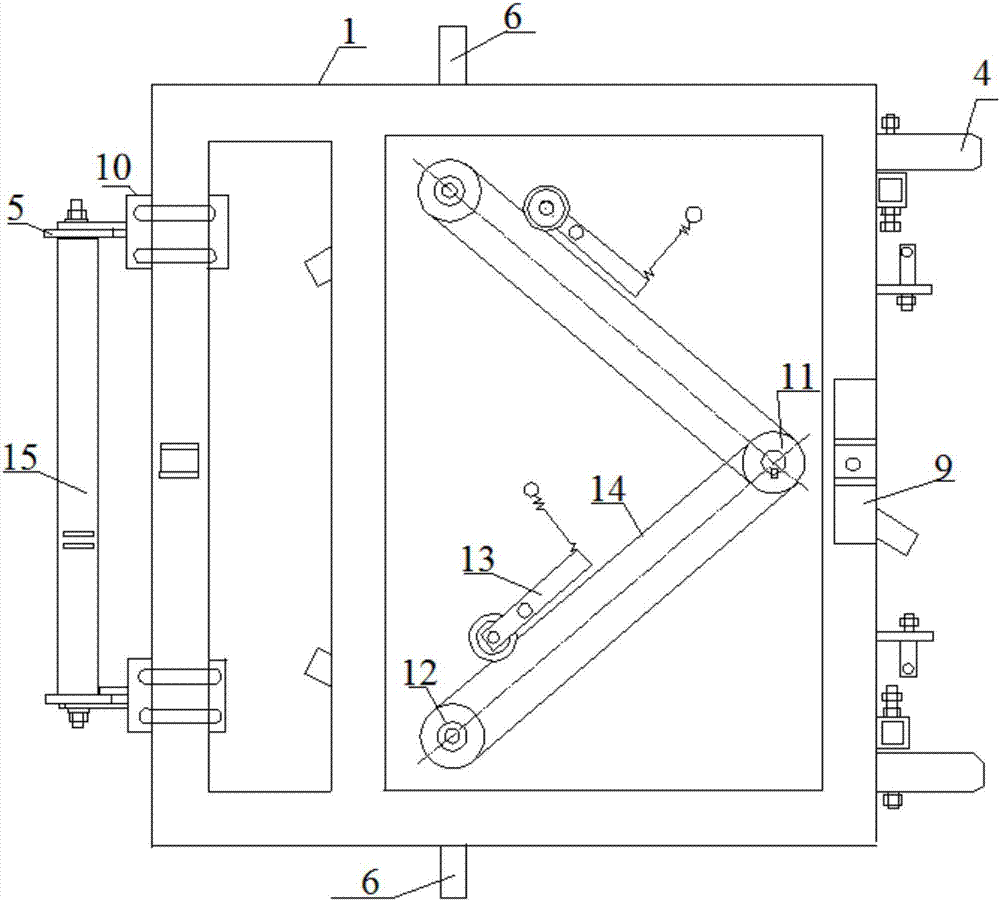

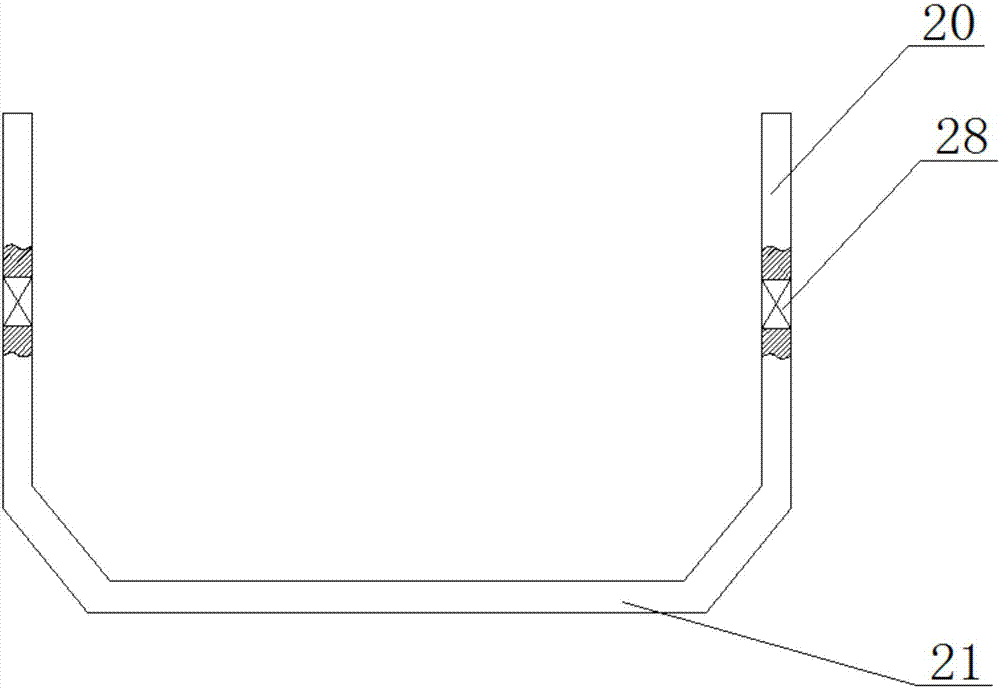

[0020] Such as Figures 1 to 4 As shown, the beet and carrot harvester in the present embodiment include a frame-type frame 1, a three-axis gearbox 2, an eccentric wheel 3, two ground wheels 4, a digging shovel 5, three tassel sweepers 6, and a pull bar 7 , support rod 8, suspension frame 9, excavating shovel connecting seat 10, a driving double sprocket 11, two driven sprockets 12, two chain tensioning devices 13, two chains 14, excavating shovel connecting pipe 15, machine Bottom 22 and machine cover 23;

[0021] Described hanger 9 is arranged on the top of the middle of frame 1 front beam; Described three-axis gearbox 2 is arranged in the middle of frame 1 front and is positioned at the back of hanger 9, and the input shaft of three-axle gearbox 2 and telescopic universal It is connected to one end of the shaft 18, and the other end of the telescopic cardan shaft 18 is used to connect with the power output shaft of the external traction device. The downward output shaft of...

Embodiment 2

[0027] Such as Figure 1 to Figure 5 As shown, in the sugar beet and carrot harvester in the present embodiment, when harvesting carrots, the tendon strips 19 and spacers 24 in the tassel sweeper 6 are replaced by three tassel cutting knives 29; three tassel cutting knives 29 They are respectively arranged on the three sleeve shafts 17 and located on the top of the fixed disk 25 . All the other structures are the same as in Example 1.

[0028] When the present invention is in use, the three-axis gearbox 2 is connected with the power output shaft of the tractor through the telescopic cardan shaft 18 . The sugar beet and carrot harvester is a three-point full suspension. The unit lands on the ground, puts down the hydraulic equipment and lands, and starts the trial operation. First, the beets are dehulled and pulverized by the sweeper 6 rotating at a high speed, and then the shovel 21 of the excavating shovel 5 of high-frequency vibration digs the beets from the ground. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com