Manually-assisted handheld gear-rack variable-diameter branch clamping grape girdling device

A technology of rack and pinion, assist hand, applied in cutting tools, gardening tools/equipment, cutting equipment, etc., can solve the problems of small turning radius, increased flower bud ratio, small spacing, etc., achieving small turning radius, convenient operation, weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

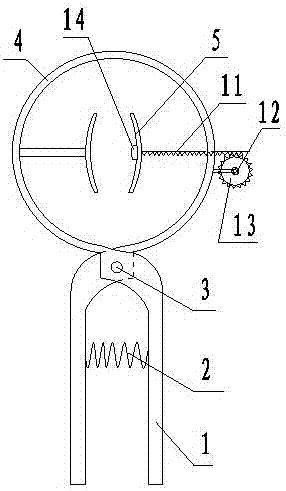

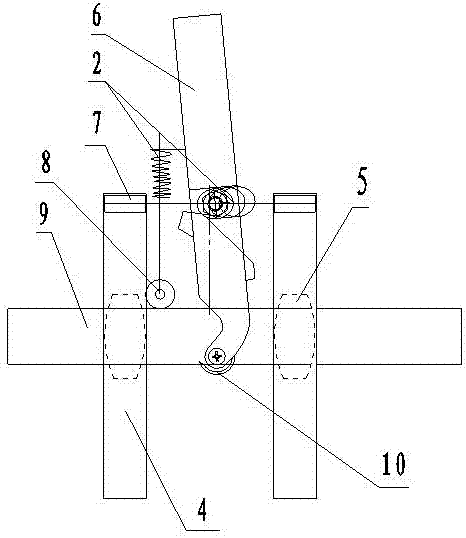

[0020] in such as Figure 1~2In the shown embodiment, a hand-held gear-and-rack variable-diameter branch clamping grape girdler with manual assistance includes a handle 1, a spring 2, a rotating shaft 3, a moving circle, a fixed circle 4, a gear 13, a rack 11 and Servo motor 12, spring 2 is fixedly installed on the handle 1, the spring 2 is a tension spring, the handle 1 is divided into two parts, the fixed circle 4 is installed on the handle 1, the fixed circle 4 is divided into two parts, and the two parts of the fixed circle 4 Buckled together to form a complete circle, the handle 1 opens and closes, and the fixed circle 4 also opens and closes accordingly. There is a groove on the fixed circle 4, and the roller 7 is embedded in the groove and rolls in the groove, making Circular movement, the connecting rod runs through the central hole of the roller 7, and the two grape girders are connected together, the girdling handle 6 is fixed on the connecting rod, one end of the gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com