A 3D adjustable laser cutting head with qbh collimator

A laser cutting head, three-dimensional adjustment technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem that the optical collimator cannot be adjusted vertically, and achieves increased vertical flexible adjustment function, improved efficiency and consistency strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the wristband rotation mechanism and the cam adjustment mechanism will be described as examples below.

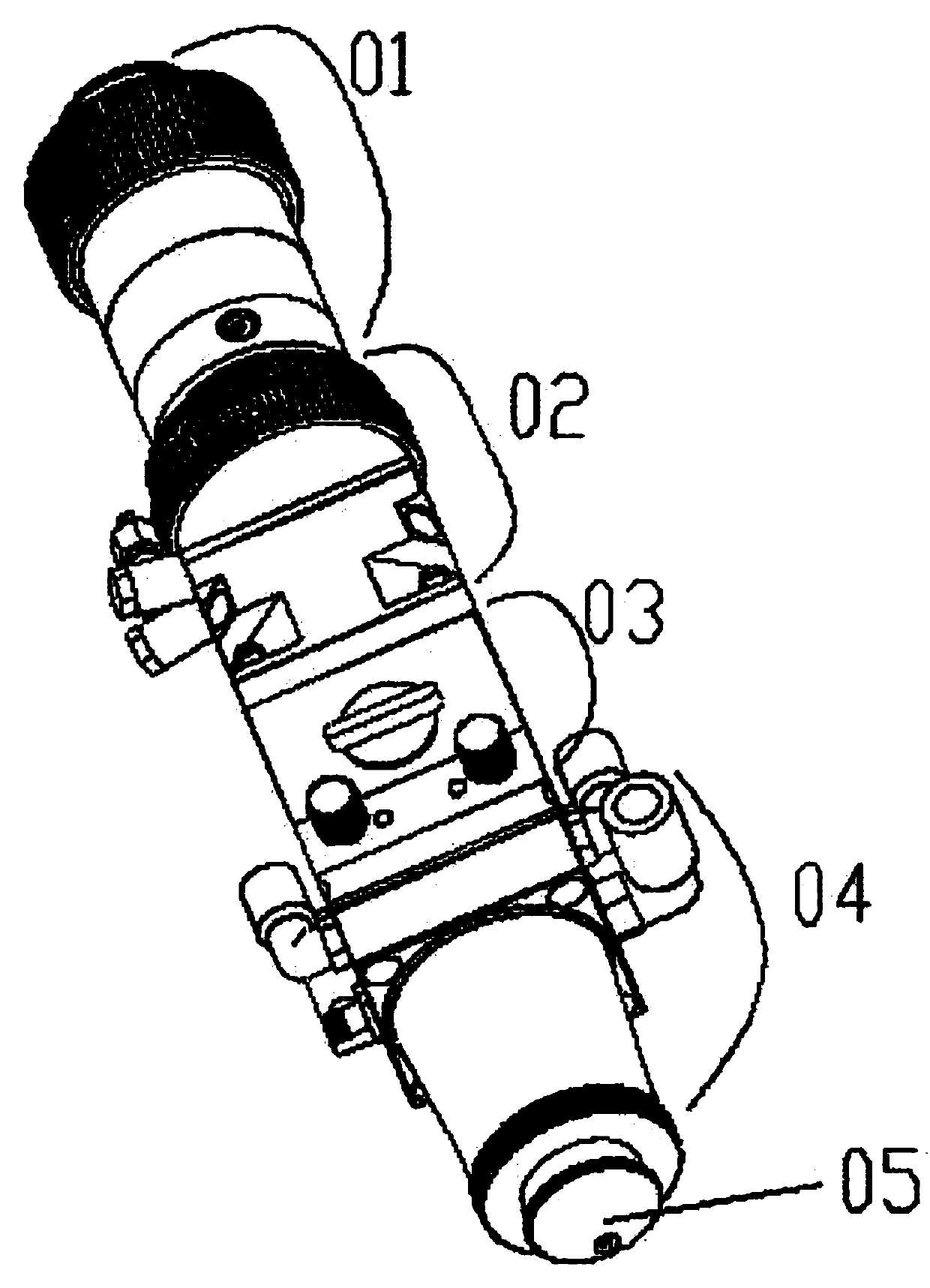

[0019] Such as figure 1 Described is the overall structure of the three-dimensional adjustment laser cutting head of the QBH collimator, which includes a QBH adapter 01, a collimator lens (group) adjuster 02, a focus lens (group) adjuster 03, a focus tracking system 04 and a nozzle 05.

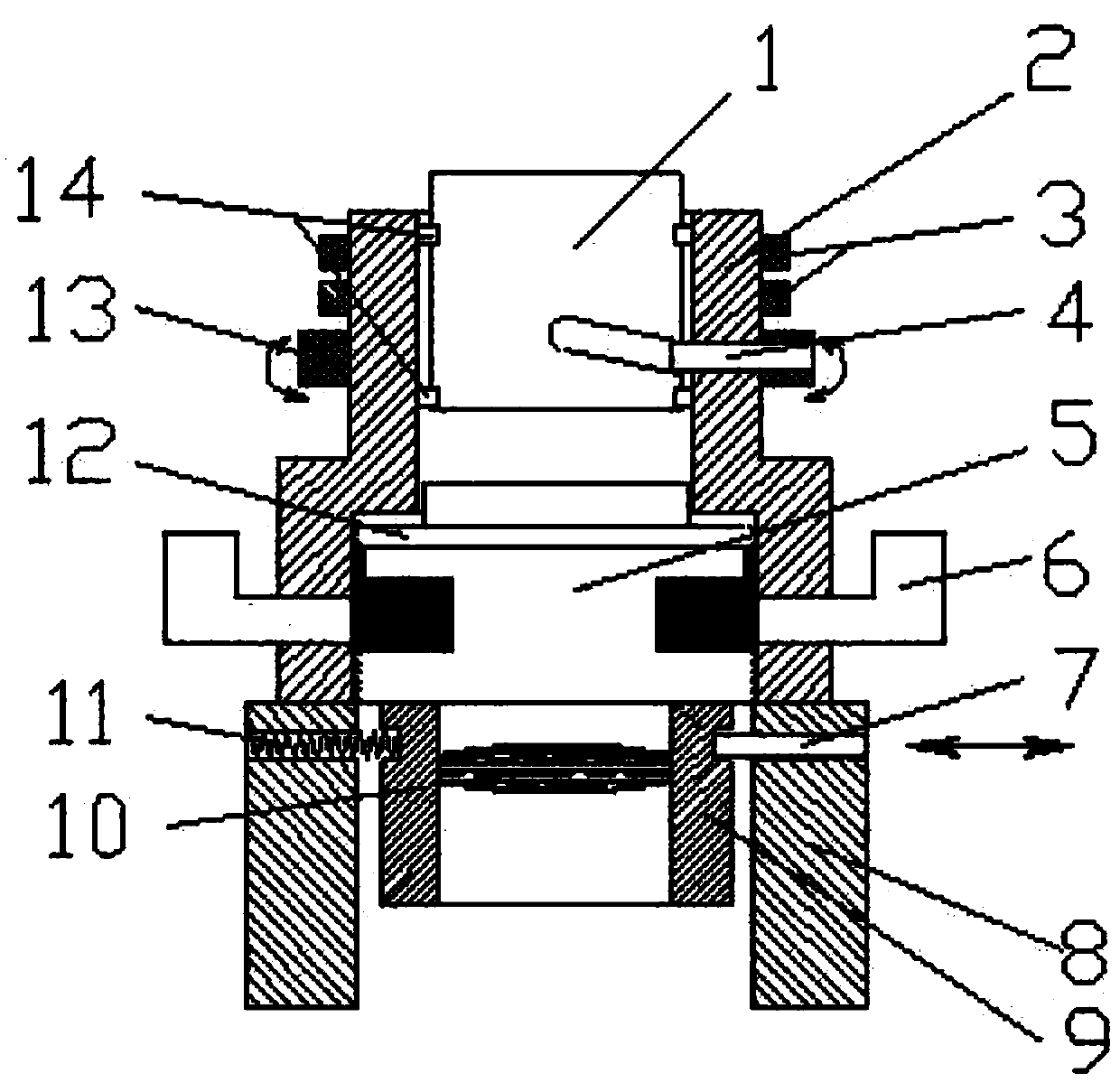

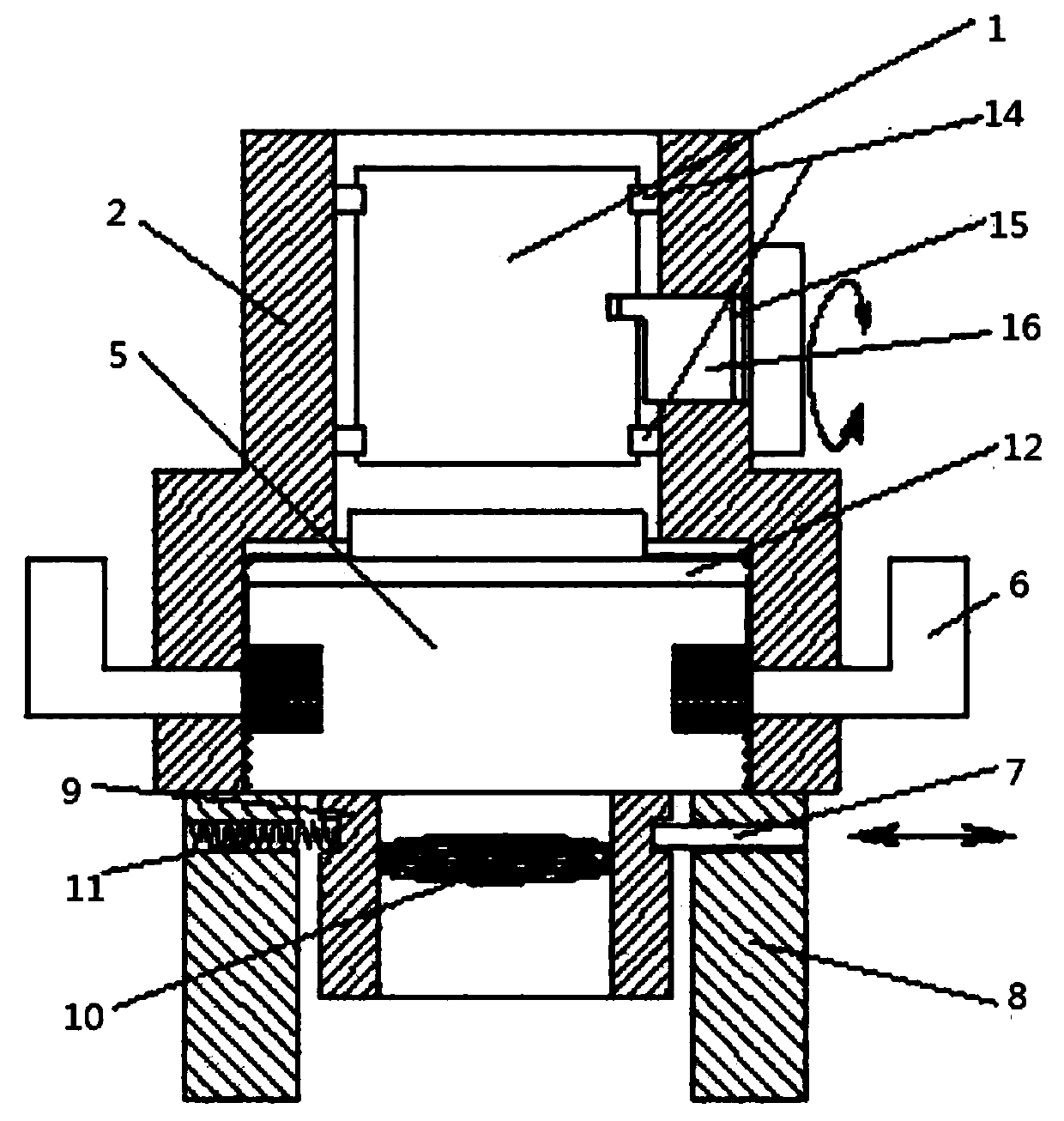

[0020] Collimator lens (group) regulator 02 wristband rotation mechanism (such as figure 2 ) contains 1-slider, 2-collimation slide cavity, 3-double nut ring, 4-pin, 5-sealing plug, 6-water pipe, 7-screw, 8-collimation cavity, 9-lens barrel, 10- Lens, 11-spring, 12-seal rubber ring, 13-bracelet, 14-pan plug seal.

[0021] The horizontal adjustment function of the wristband rotation mechanism squeezes the collimator lens barrel through one end of the spring 11, and fixes it by glue at the other end, so that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com