Positioning and clamping device for machining plate parts and using method of positioning and clamping device

A disc-type part, positioning and clamping technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of large processing removal, insufficient precision, and large difference in axial space position, and achieve improved processing. Quality and yield, avoid machining deformation, counteract the effect of circumferential cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

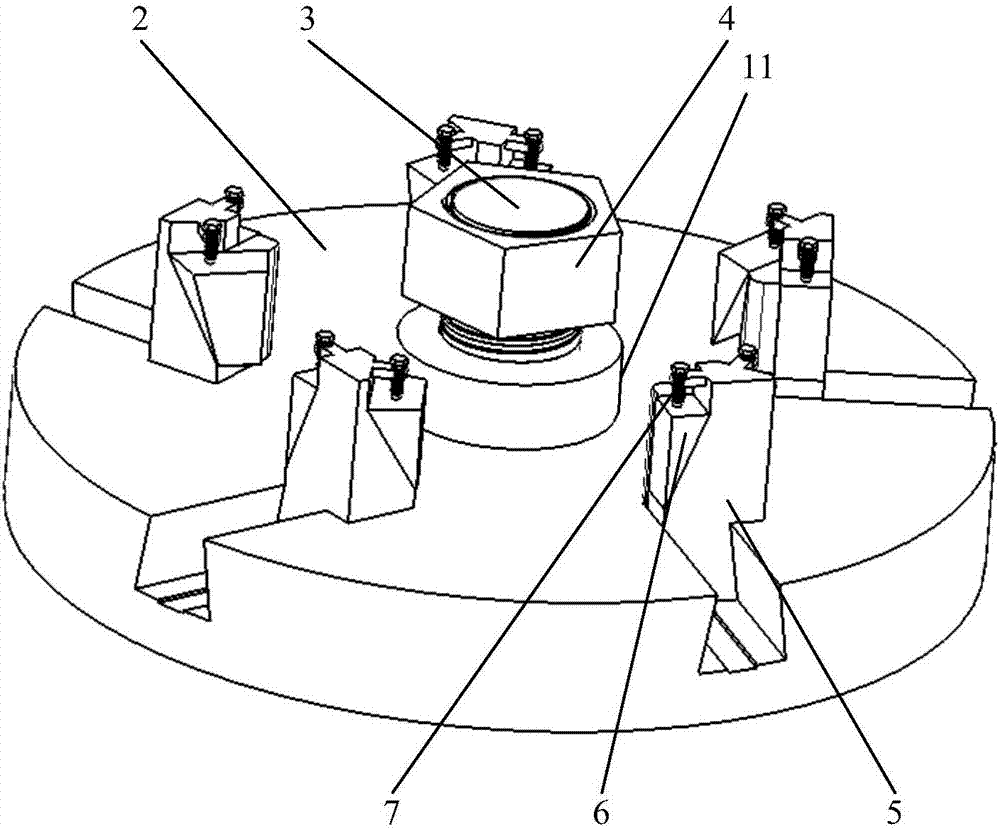

Embodiment 1

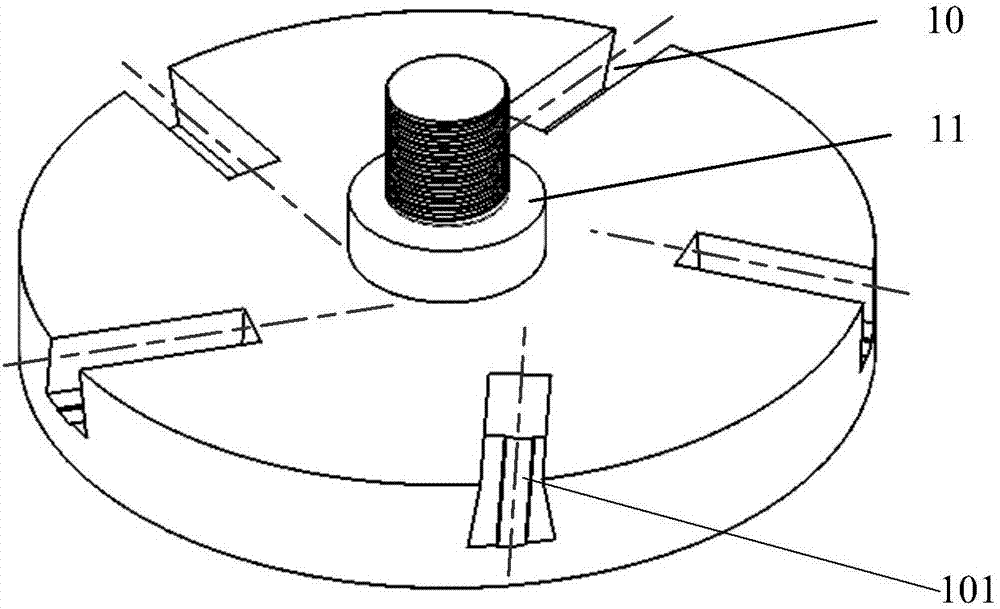

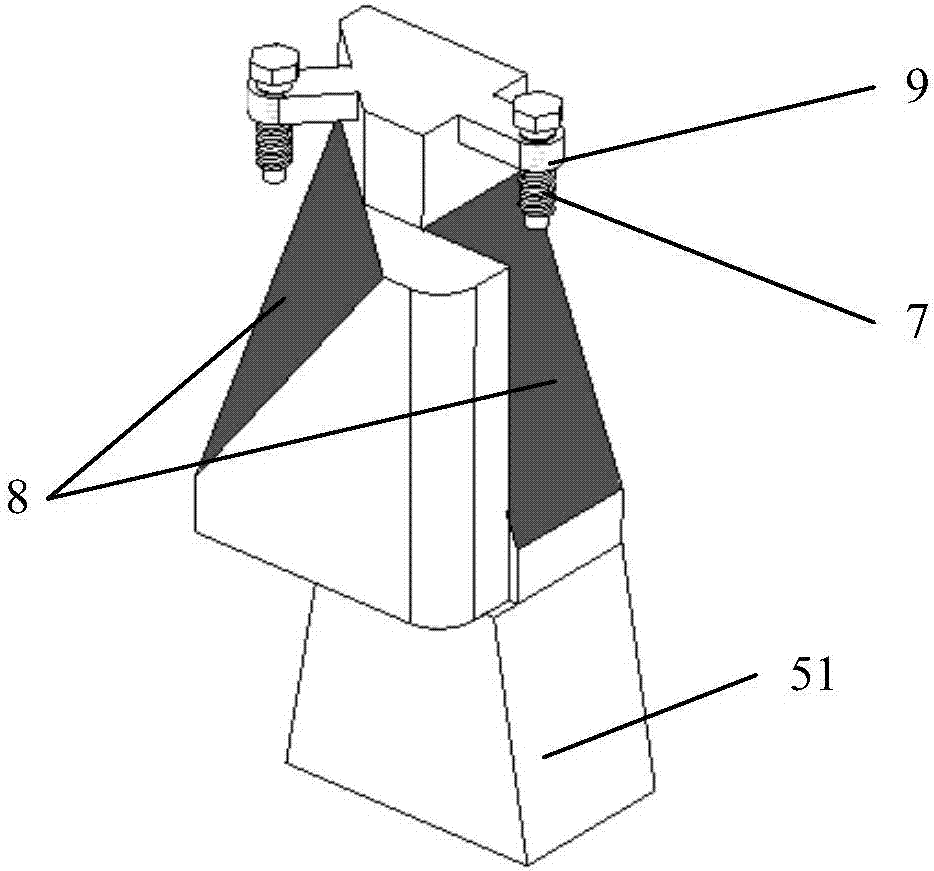

[0035] Such as Figure 5 As shown, what is to be processed in this implementation is a typical disc part diesel engine injector flange 1, which is generally in the shape of a disc with a large radial dimension and a small axial direction, with a circular inner hole in the center and a stepped end surface. Five characteristic structures and their corresponding positioning parts are symmetrically distributed in the center. The size and shape parameters of the positioning parts are the requirements of the fixed clamping device (especially the moving slider 5, the upper slide rail 10 of the fixture base 2 and the clamping pressure block 6). Design Basis. Flange 1 of injector of diesel engine has the characteristics of typical disk parts such as large disk and thin wall, complex structure, and large amount of cutting and processing. It is easy to process deformation in the two-pass milling process of its groove shape and slide rail 10 sides, which needs to be solved. The problem o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com