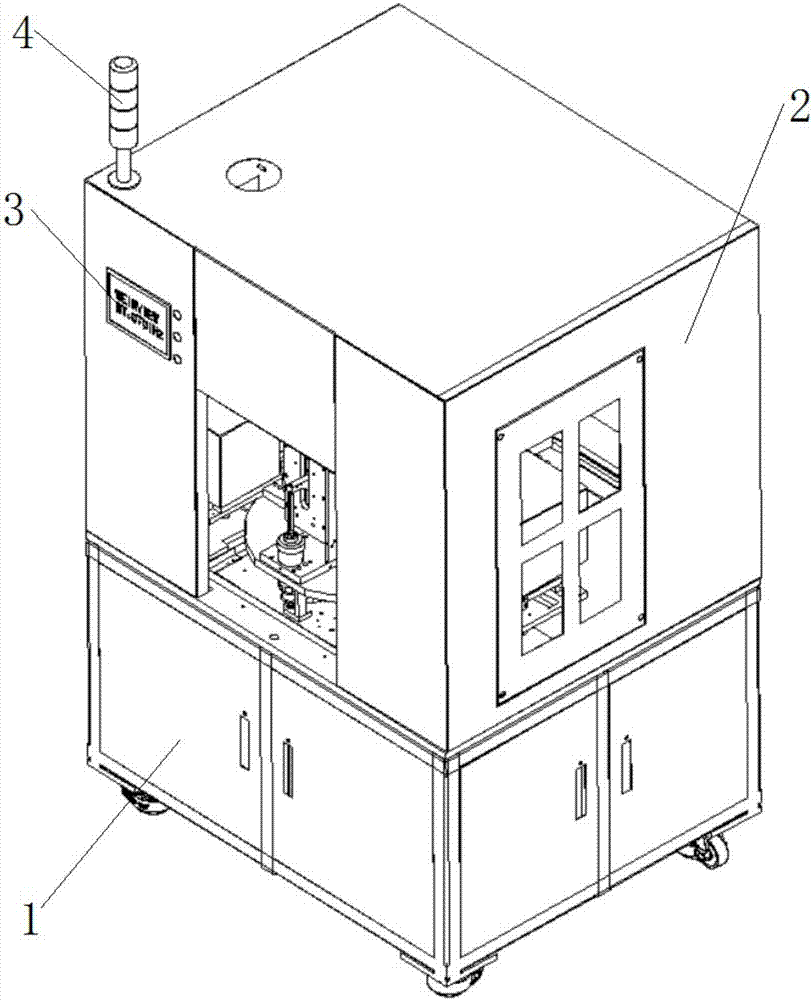

Automatic polishing machine

An automatic polishing and rack technology, applied in the field of mechanical processing, can solve the problems of high processing cost, low work efficiency, and relatively high requirements for the control accuracy of the robot's rotating back axis, so as to reduce process costs, reduce losses, and improve production efficiency and products. The effect of quality pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

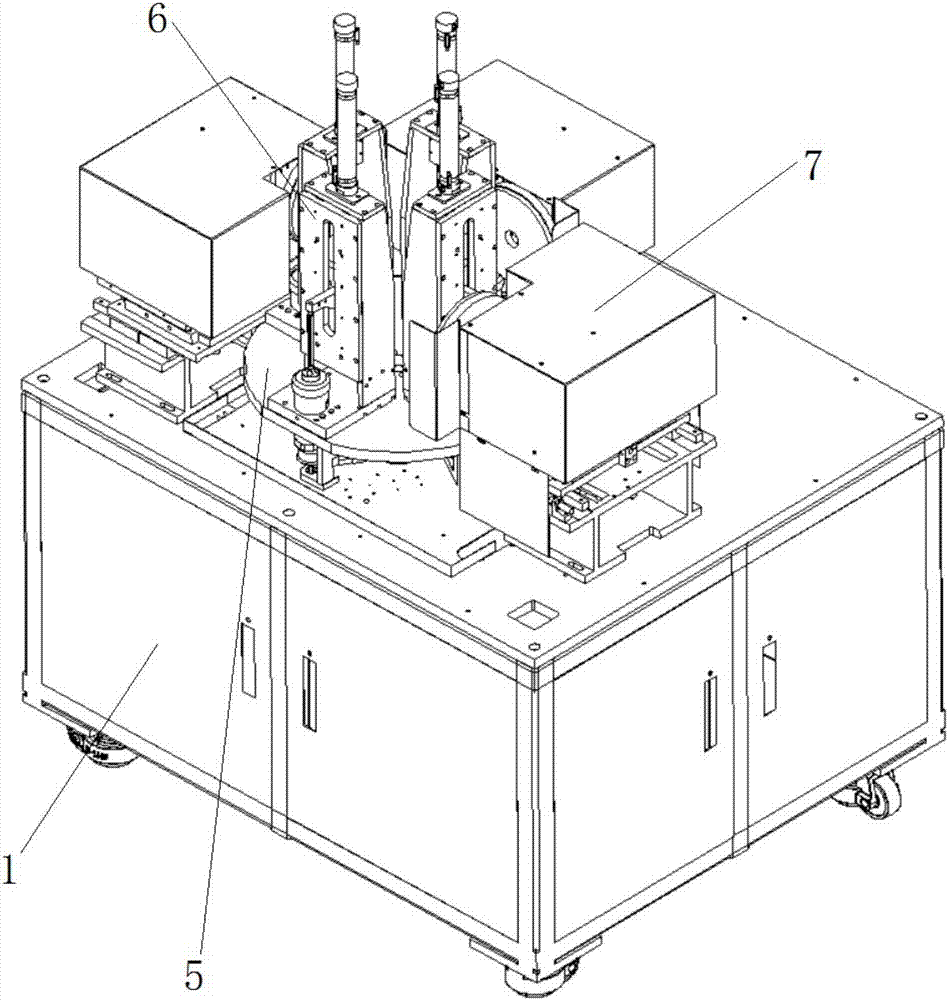

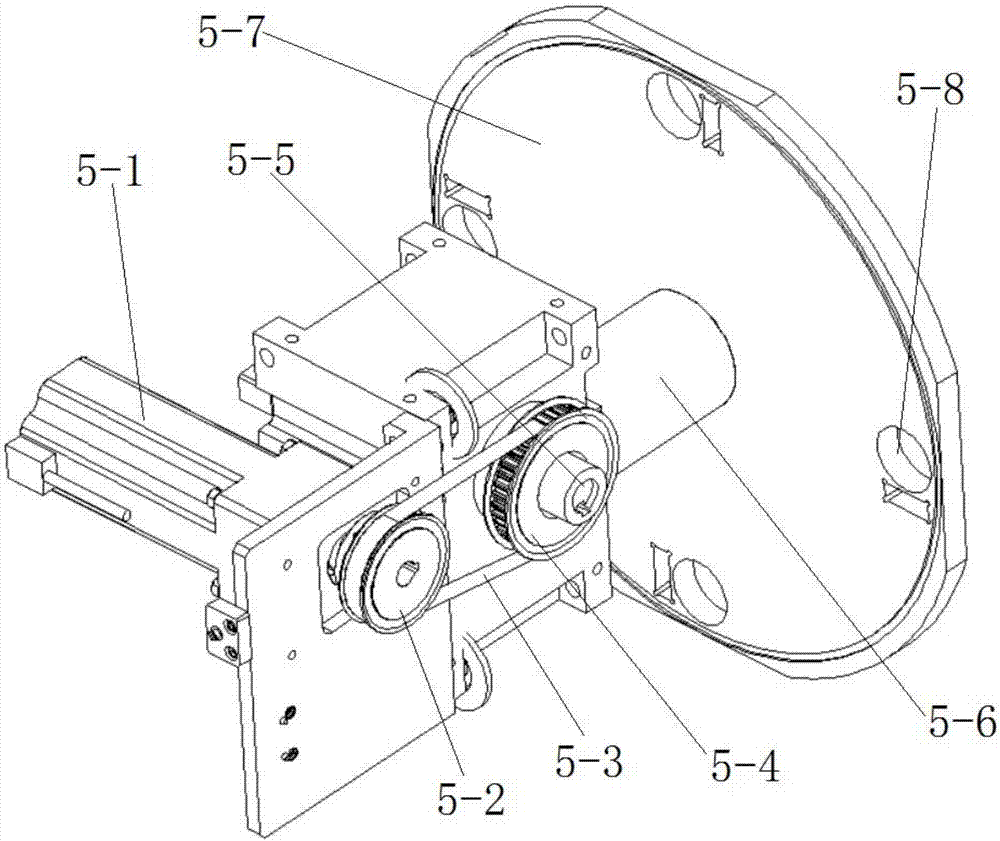

[0029] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

[0030] In order to solve the above-mentioned technical problems in the grinding and polishing of special-shaped pipe shaft parts, according to the grinding principle, the present invention designs a special automatic polishing machine. Its design principle is expanded according to the following requirements.

[0031] First of all, it is necessary to ensure that the polished shape of the product can meet the accuracy requirements of the product's shape and hub. That is to say, the size of the finished product must be guaranteed, so it is necessary to ensure that the amount of grinding can be controlled during grinding. Secondly, it is also necessary to use this process to eliminate scratches and scratches on the appearance of the product during clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com