Floor based on elastic interlayer

A sandwich and elastic technology, applied in the floor field based on elastic interlayer, can solve the problems of loss of floor elasticity, lower PVC film hardness, poor compression resistance, etc., to ensure bearing capacity and stability, improve comfort, and good compression resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

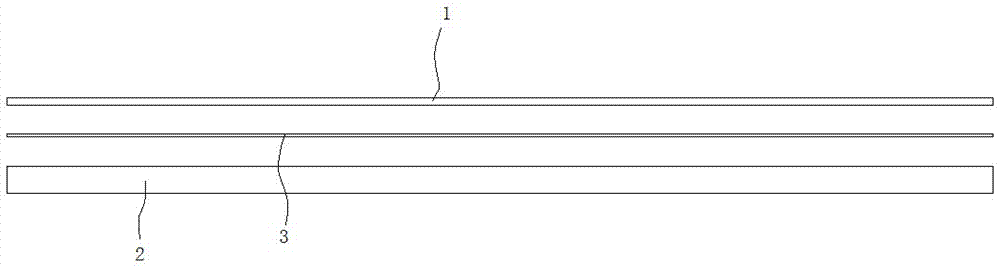

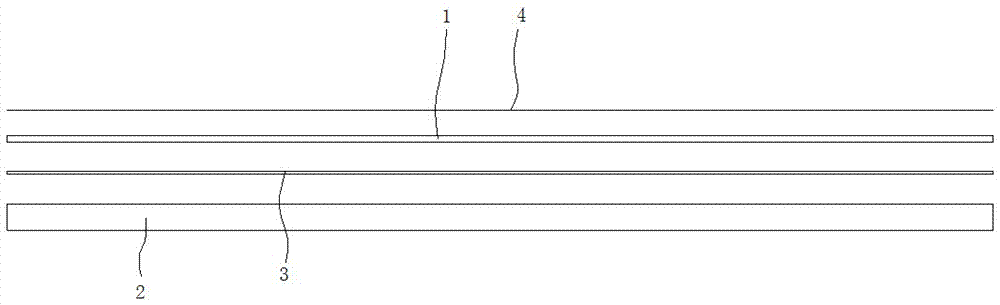

[0020] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 7 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0021] The present invention is a floor based on an elastic interlayer, comprising an upper surface layer 1 made of a hard material and a lower bottom layer 2 made of a hard PVC material, and an elastic interlayer 3 is arranged between the upper surface layer 1 and the lower bottom layer 2 .

[0022] Preferably, the upper surface layer 1 is a hard PVC material layer, or a ceramic layer, or a glass layer, or a metal layer, or a stone layer; the elastic interlayer 3 between the upper surface layer 1 and the lower bottom layer 2 is formed by an air cushion, or Made of foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com