Control of exhaust gas purification system

A technology for exhaust purification and exhaust ducts, which is applied in the direction of exhaust devices, exhaust treatment, and electronic control of exhaust treatment devices to achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

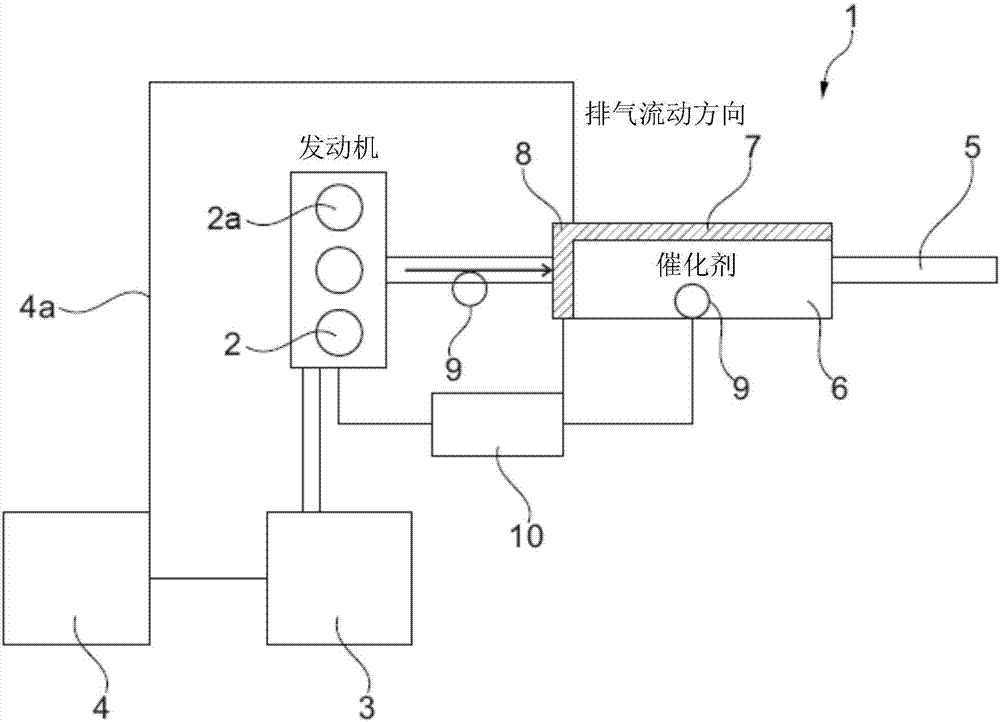

[0027] according to figure 1 The illustrated device 1 comprises an internal combustion engine 2, which may be a self-ignition internal combustion engine or an external ignition internal combustion engine. The internal combustion engine 2 has three cylinders 2a, but can alternatively also have 2, 4, 5, 6 or 8 cylinders. The internal combustion engine 2 is further connected to a generator 3 for charging a first rechargeable battery 4 of the motor vehicle. An exhaust passage 5 is connected to the internal combustion engine 2 so as to discharge exhaust gas. An exhaust aftertreatment system 6 is arranged in the exhaust passage 5 . The exhaust gas aftertreatment system 6 contains at least one catalytic converter 7 , such as an oxidation catalytic converter, a particulate filter, a nitrogen oxide storage catalytic converter and / or a catalytic converter for selective catalytic reduction.

[0028] The electric heating device 8 is arranged in connection with the catalytic converter 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com