Ceiling lamp with square anti-dazzle cups and bicolor spraying technology of ceiling lamp

A ceiling lamp and anti-glare technology, applied in cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of unsightly industrial design, scatter of peripheral light, and lack of innovation, etc., to achieve Beautiful industrial design, simple manual assembly, and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

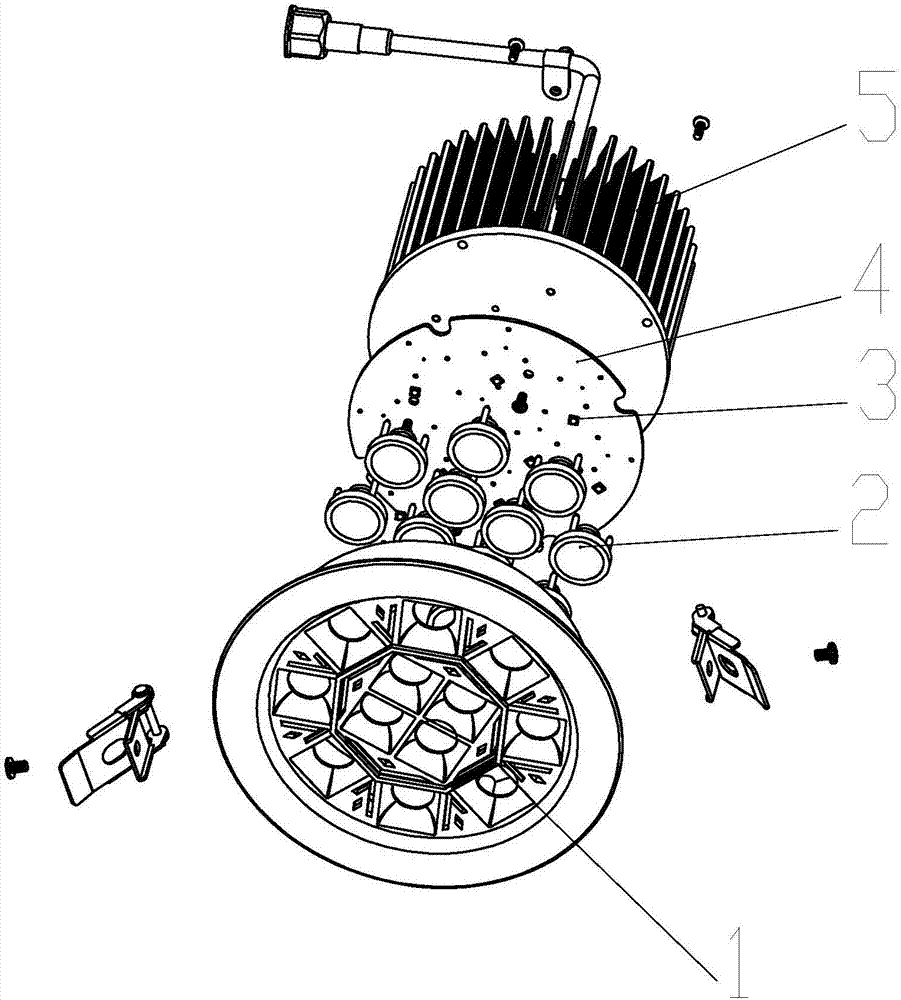

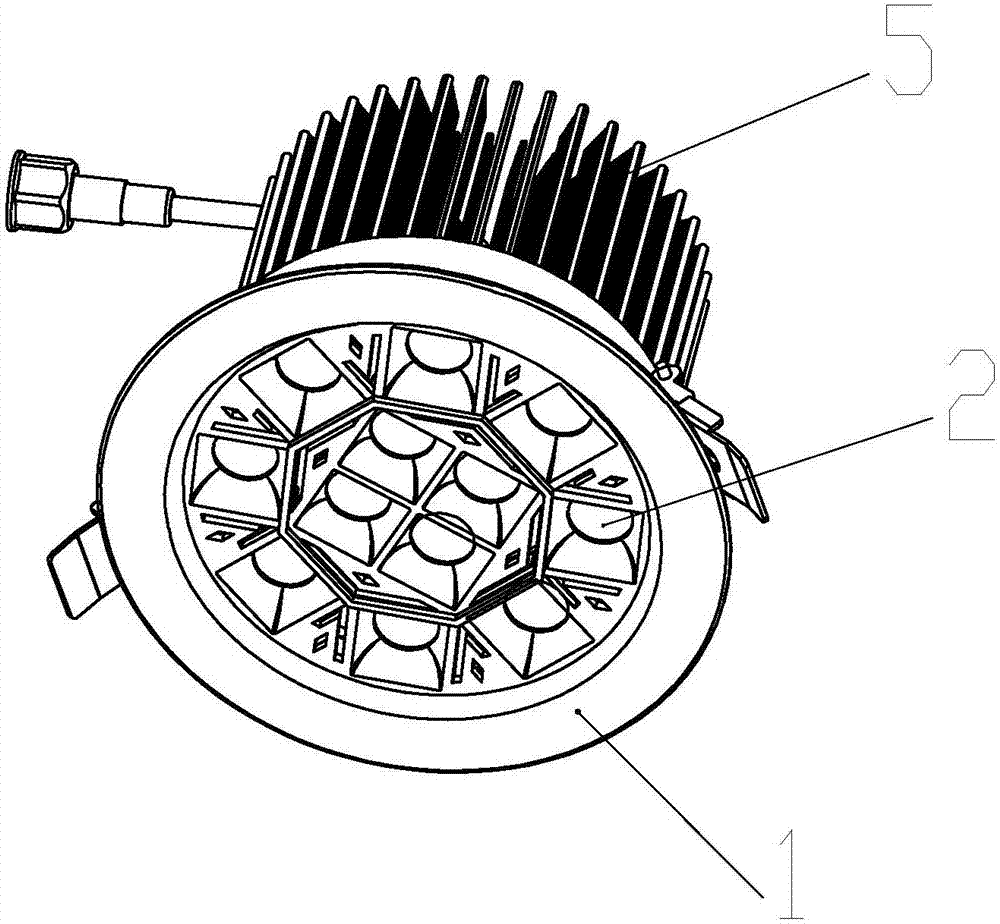

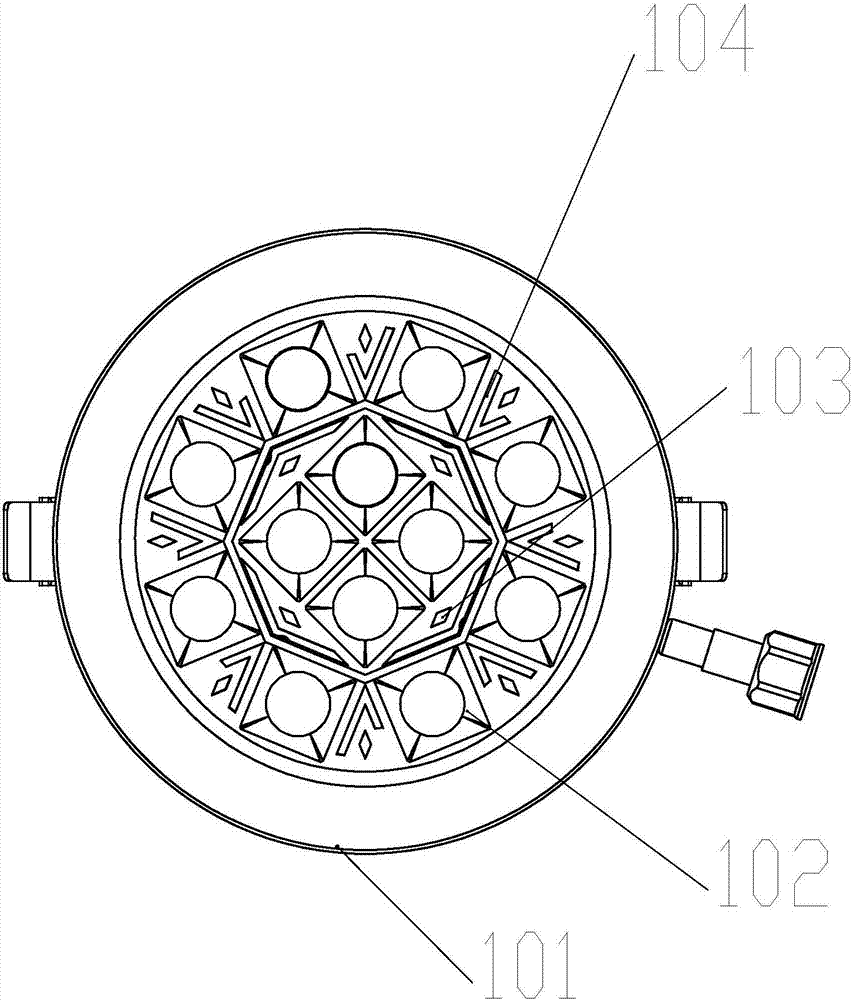

[0029] Such as Figure 1-3 As shown, a specific embodiment 1 of a square anti-glare cup 102 ceiling lamp of the present invention and its two-color spraying process includes a cover 1, a lens bracket 2, an LED lamp bead 3, a lens, a heat sink 5, a PCB board 4 and Screws; the cover 1 is provided with an anti-glare lamp cup, and the anti-glare cup 102 is a square shape, arranged in a cross dividing line, and the LED lamp beads 3 are welded on the PCB board 4, and the surface of the LED lamp beads 3 is provided with a lens; the cover 1 The anti-glare cup 102 is assembled on each surface of the lens holder 2, and the lens holder 2 is located on the lens correspondingly;

[0030] Square anti-glare cup 102 ceiling lamp and its two-color spraying process operation method:

[0031] a. The curved square anti-glare surface of the square anti-glare lamp cup is treated with black frosting;

[0032] b. The surface of the lens holder 2 is sprayed with black paint;

[0033] c. Spray the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com