Multi-layer flat rotating circulating type grain drying machine

A grain dryer and recycling technology, applied in dryers, drying, grain drying and other directions, can solve the problems of inability to move, high processing costs, damaged grain installation costs, etc., to improve the efficiency of reducing moisture and occupying land Small area and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

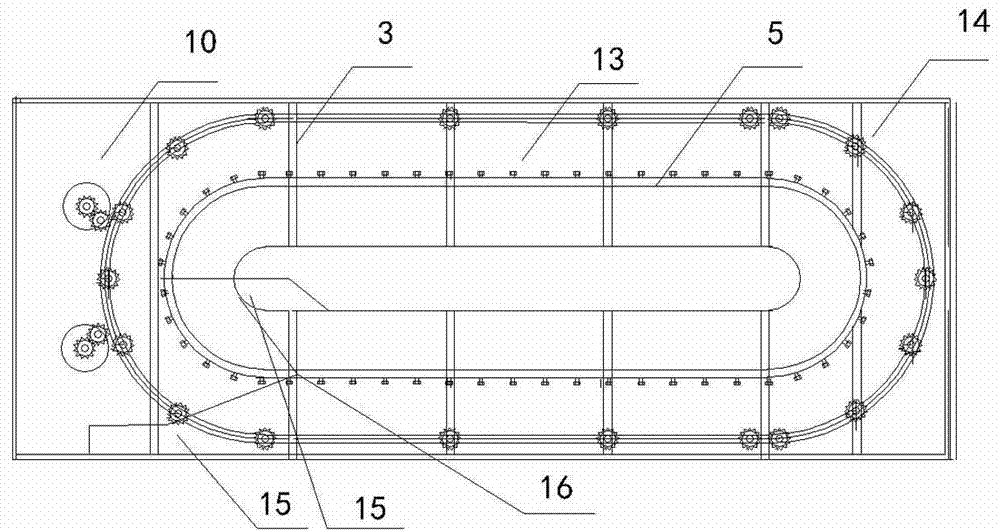

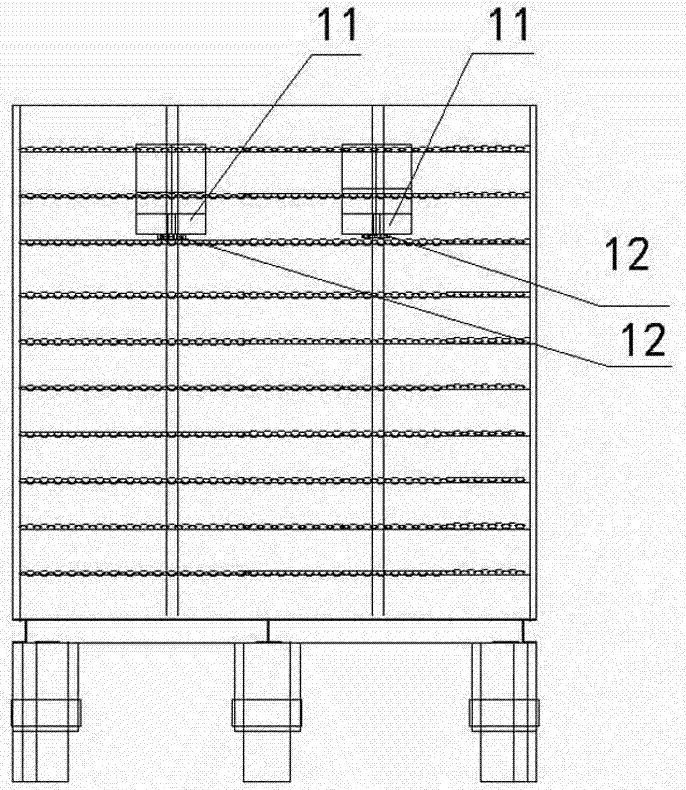

[0042] The multi-layer horizontal rotation circulation grain dryer includes a dryer box, a motor 10 and a reducer 11 inside the box, and its structure is as follows: a grain inlet 6 is arranged on the box, and an outlet Grain port 9, the inside of the box is provided with an air inlet channel 1 and an air outlet channel 2, the hot air enters the inside of the box through the air inlet channel 1, passes through the upper and lower air channels 7 in front, turns upward into the air outlet channel, and is output by the air outlet channel 2 .

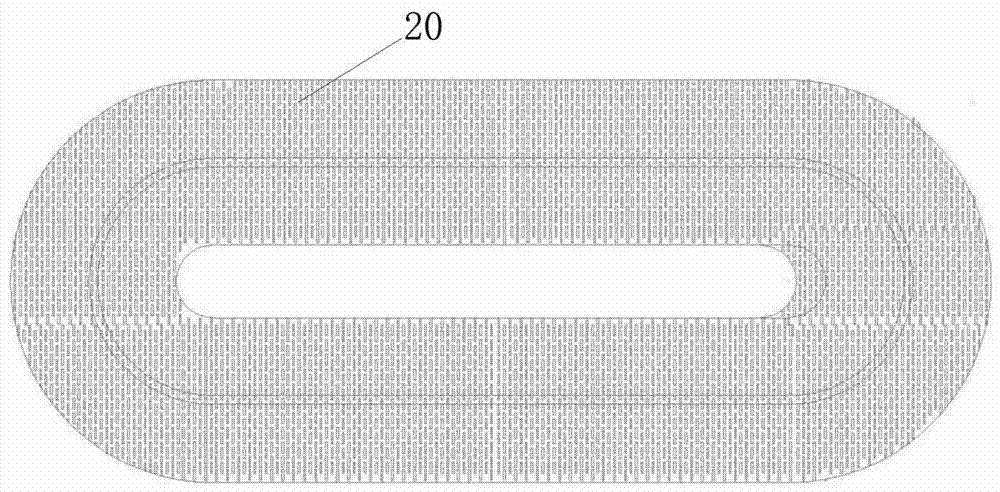

[0043] There are multiple layers of conveyor belts 20 parallel to each other from top to bottom inside the box. Each layer of conveyor belt 20 is in a closed-loop structure and the upper and lower adjacent conveyor belts 20 present opposite rotation directions. Grain enters the conveyor belt 20 from the grain inlet 6 After the conveyor belt 20 rotates a circle, it is blocked by the grain distribution plate 16 and transferred to the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com