Weber self single/even recognition and automatic combustion-rule empirical parameter calibration method

A technology of empirical parameters and automatic calibration, which is applied in the direction of internal combustion engine testing, engine testing, measuring devices, etc., can solve the problem of high difficulty in calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

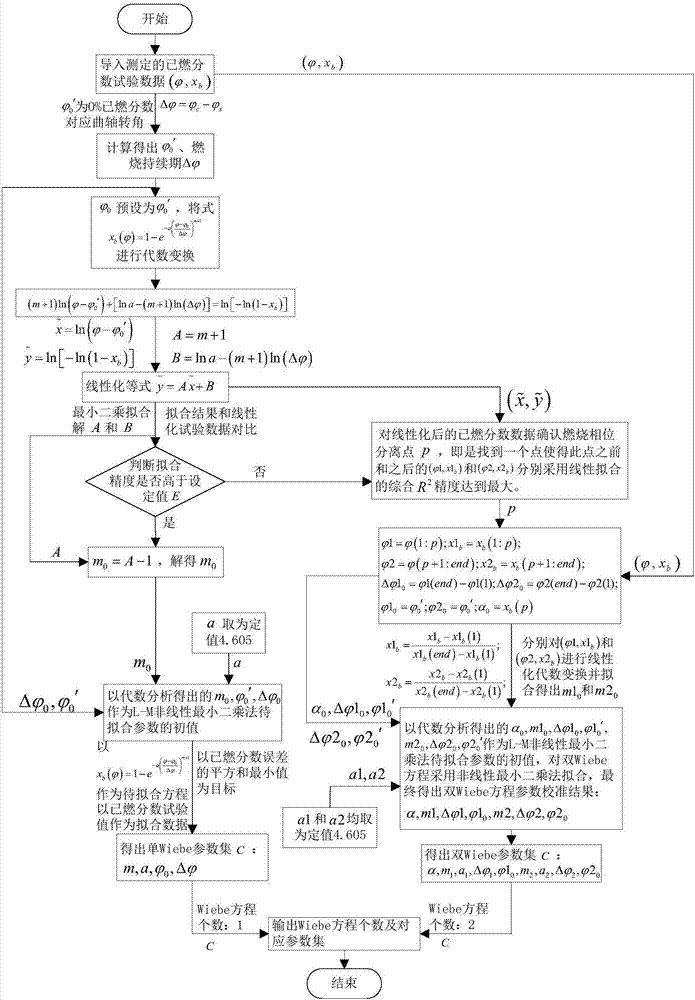

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

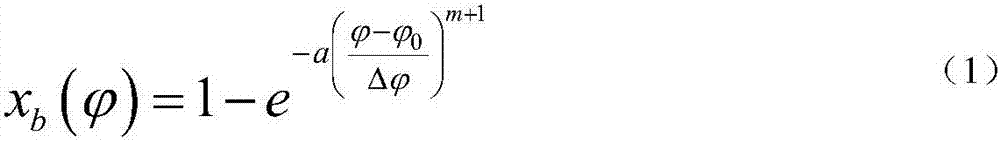

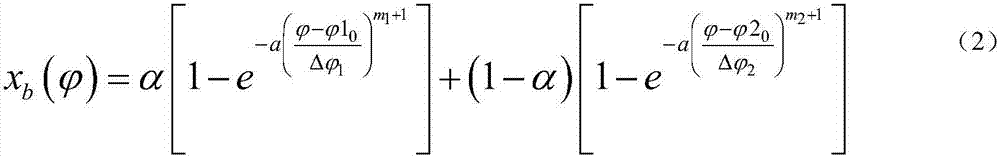

[0019] combine figure 1 , the single and double Wiebe combustion rules commonly used in the zero-dimensional combustion modeling of internal combustion engines, respectively, the parameter equations shown in formula (1) and formula (2).

[0020]

[0021]

[0022] In formula (1): x b is the percentage of burned fuel; m is the combustion quality index; a is the combustion efficiency factor; — Instantaneous crankshaft angle; — combustion duration angle; - The starting point of combustion. where m, a, and and are empirical parameters to be calibrated. In formula (2): x b is the percentage of burned fuel; m 1 and m 2 are the combustion quality indices of the first and second Wiebe equations respectively; a 1 and a 2 are the combustion efficiency factors of the first Weber (Wiebe) and second Weber (Wiebe) equations; — Instantaneous crankshaft an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com