Dummy neck calibration device and dummy neck calibration method

A calibration device and neck technology, which is applied in the field of dummy crash test devices, can solve problems affecting the accuracy of crash tests, increase dummy head and neck loss, head and neck impact, etc., and achieve simple structure, simplified structure, and faster speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

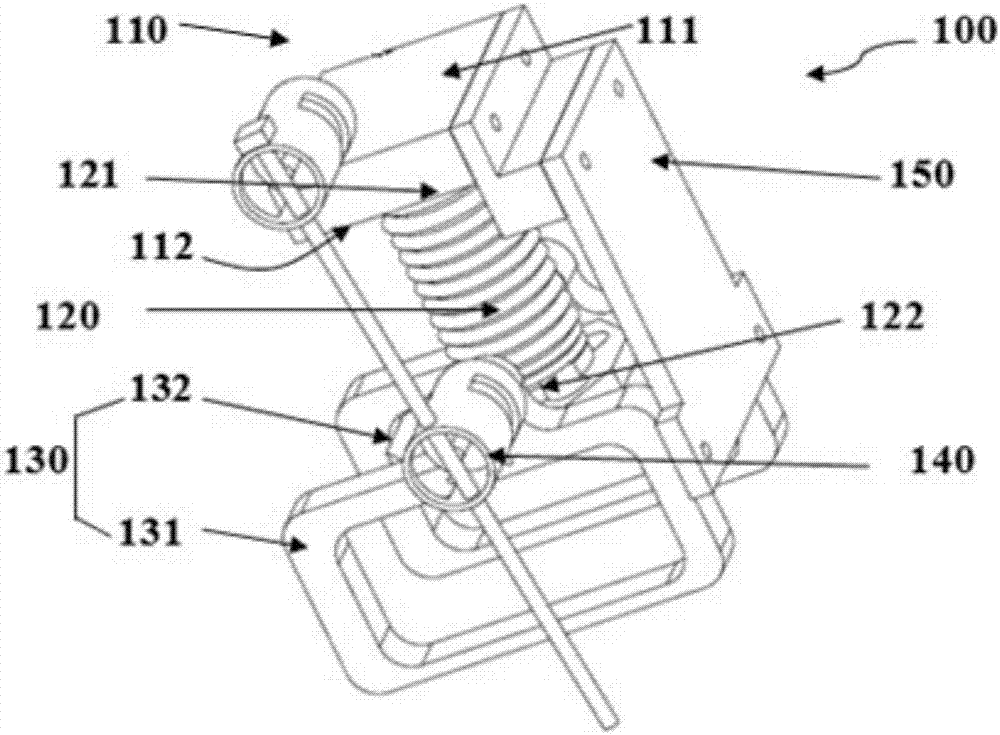

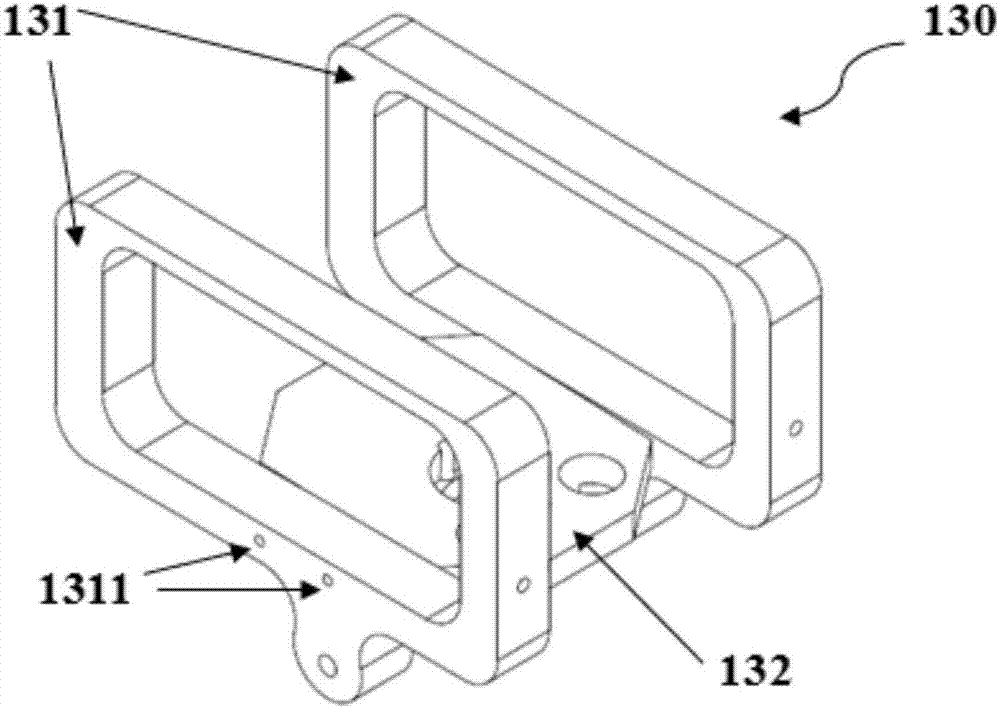

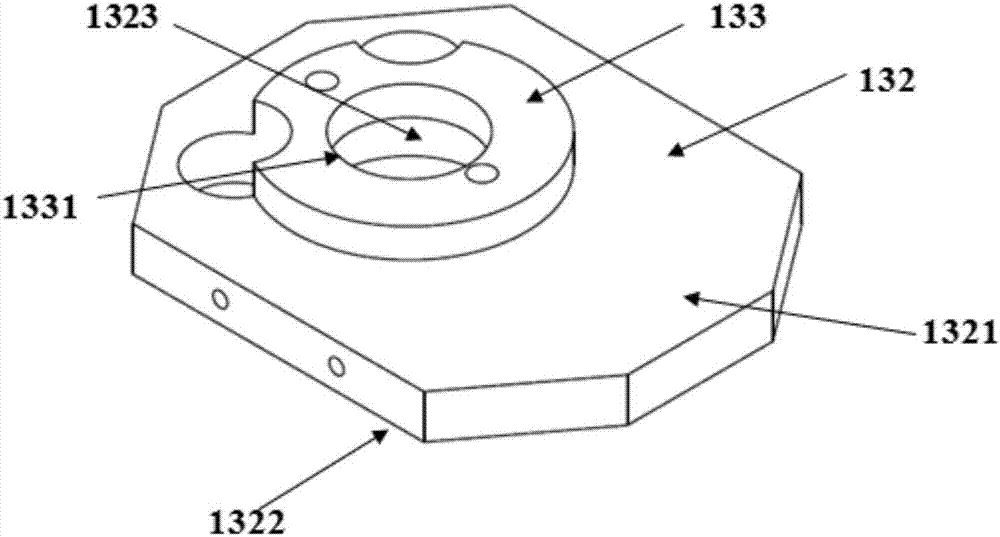

[0042] figure 1 It is a schematic structural diagram of a dummy neck calibration device 100 according to an embodiment of the present invention. The dummy neck calibration device 100 of the present invention is used to calibrate the dummy neck installed on a pendulum calibration system, so as to improve the accuracy of dummy neck calibration. The dummy neck calibration device 100 may include a pendulum connection part 110 , a neck part 120 , a head part assembly 130 and an angle measurement mechanism 140 .

[0043] Such as figure 1As shown, the pendulum connecting part 110 is installed at the end of the swing arm of the pendulum calibration system for fixing the dummy neck calibration device 100 at the pendulum calibration system. The pendulum connecting part 110 has an opposite upper surface 111 and a lower surface 112 , the upper surface 111 is fixedly connected to the end of the swing arm, and the lower surface 112 is the side opposite to the upper surface 111 . The dumm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com