A wire winding device between soldering power cord core and enameled wire

A technology for power cords and enameled wires, applied in circuits, electrical components, cable/conductor manufacturing, etc., can solve the problems of affecting the quality of wire winding, soldering quality, not very practical, tremor errors, etc., to achieve simple structure, simple control, avoidance of The effect of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

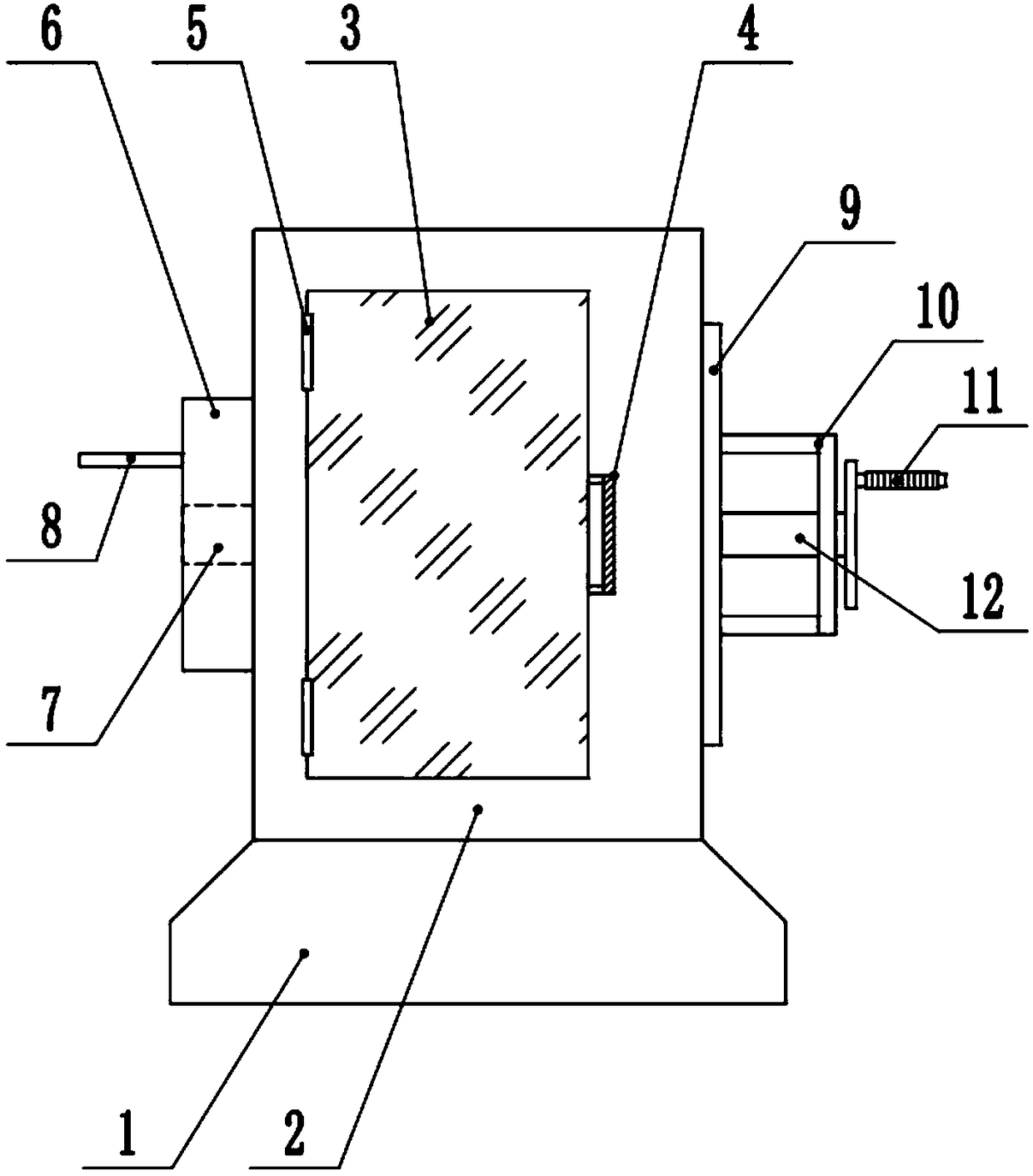

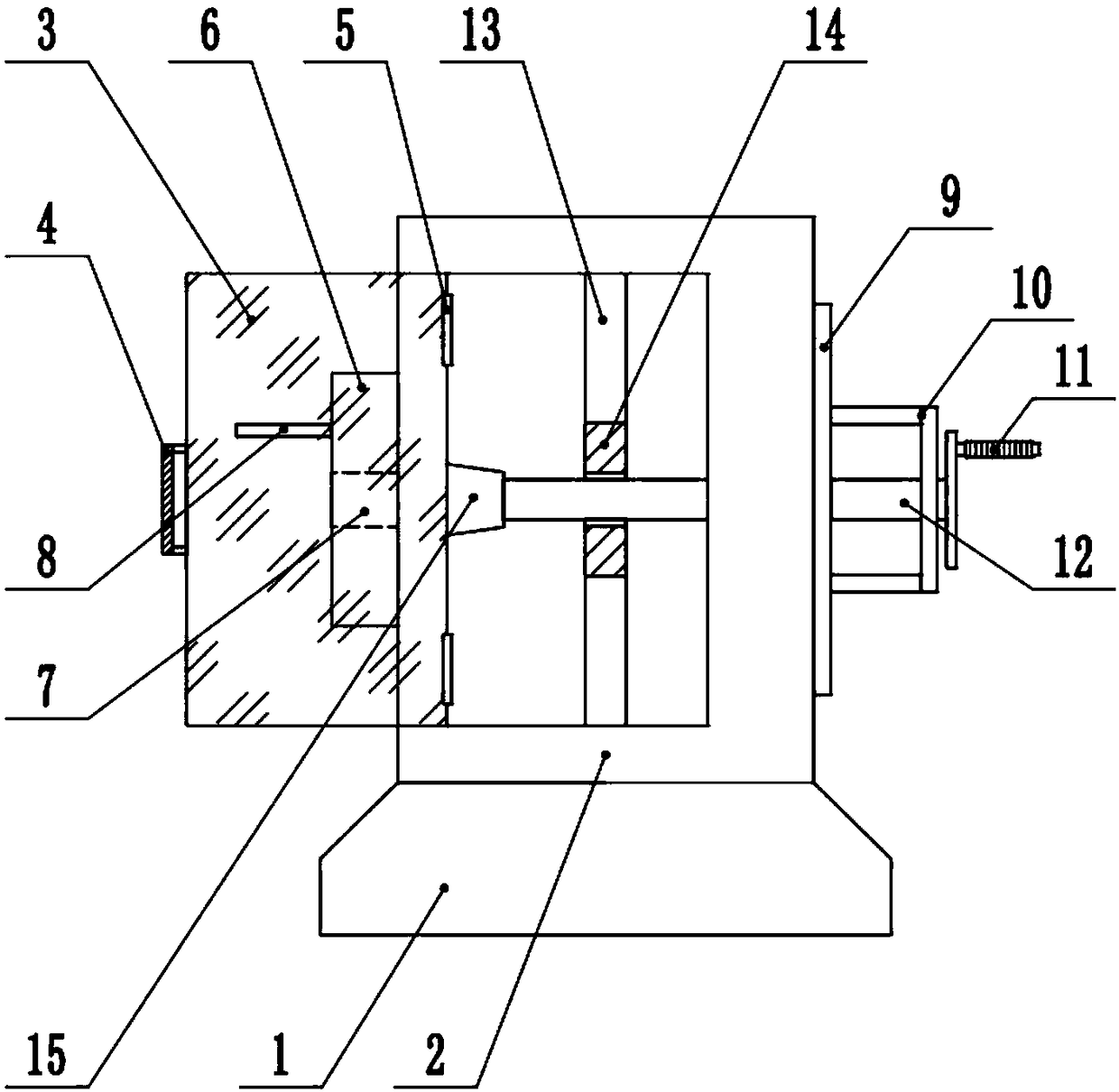

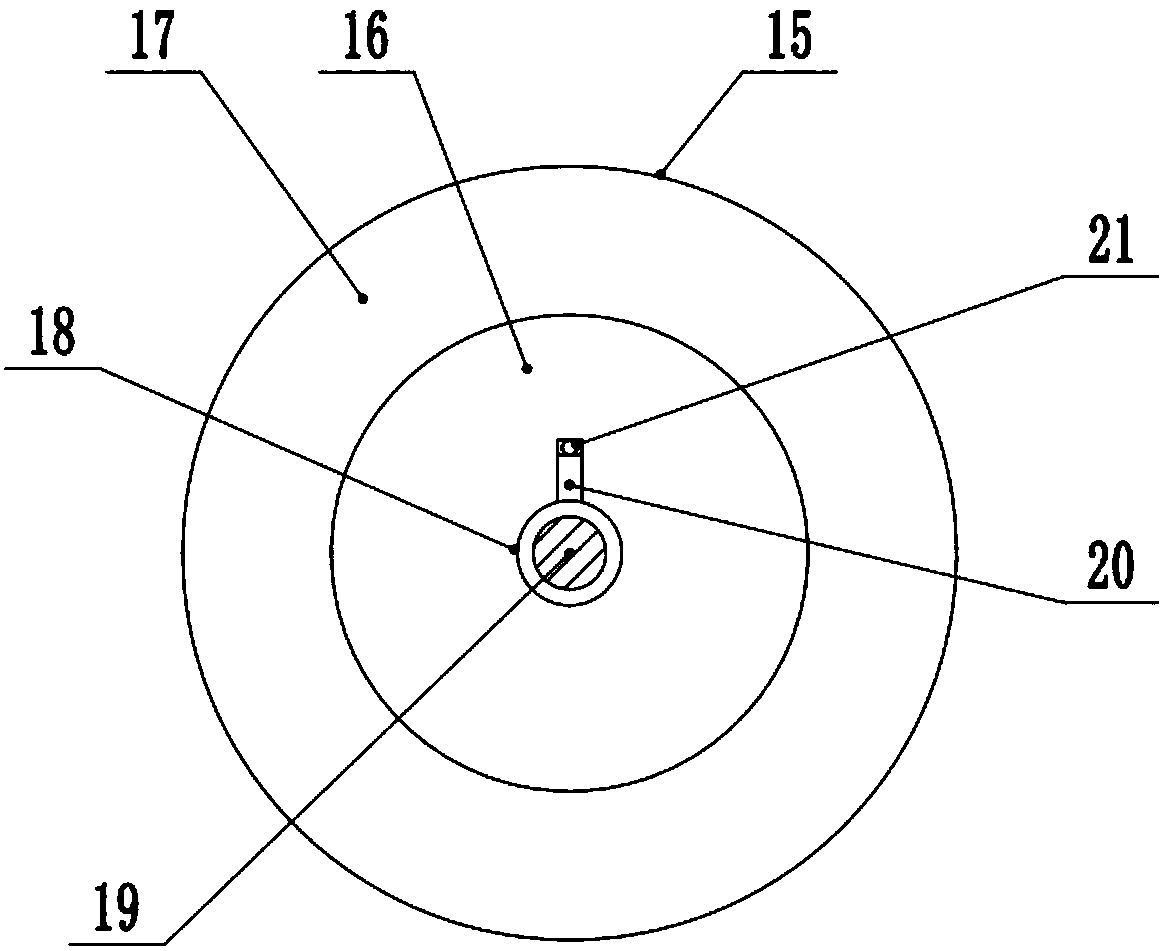

[0017] See Figure 1-3 , A wire winding device between a solder power cord core and an enameled wire, comprising a device body, a base 1 is arranged at the bottom of the device body, and a housing 2 is arranged above the base 1, between the housing 2 and the base 1. The housing 2 is fixedly connected by welding, the housing 2 is a hollow structure, and an observation window 3 is provided on the front of the housing 2, and the observation window 3 and the housing 2 are rotatably connected by the action of a hinge 5. The observation window 3 A handle 4 is provided on the right side of the, and the handle 4 is fixedly connected with the observation window 3 through the action of a fixing screw, and the observation window 3 is connected with the housing 2 through a buckle. The left side of the housing 2 A plug-in positioning plate 6 is provided on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com