Bending and flattening mold and bending and flattening mold assembly

A mold and flat mold technology, applied in the field of bending flat mold and bending flat mold group, can solve the problems of large production cycle and many production processes, and achieve the effect of small production cycle, saving space and reducing production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

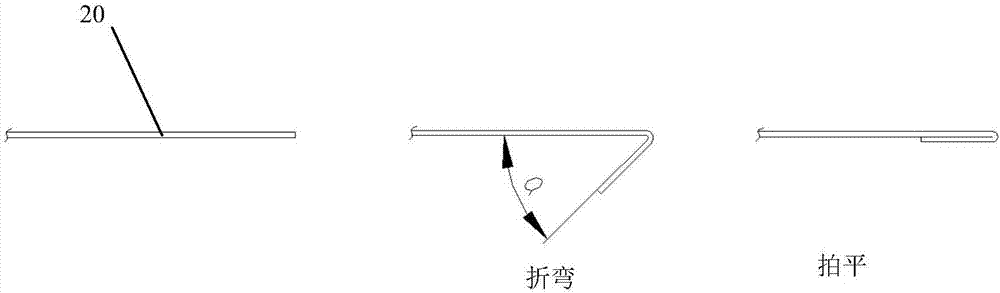

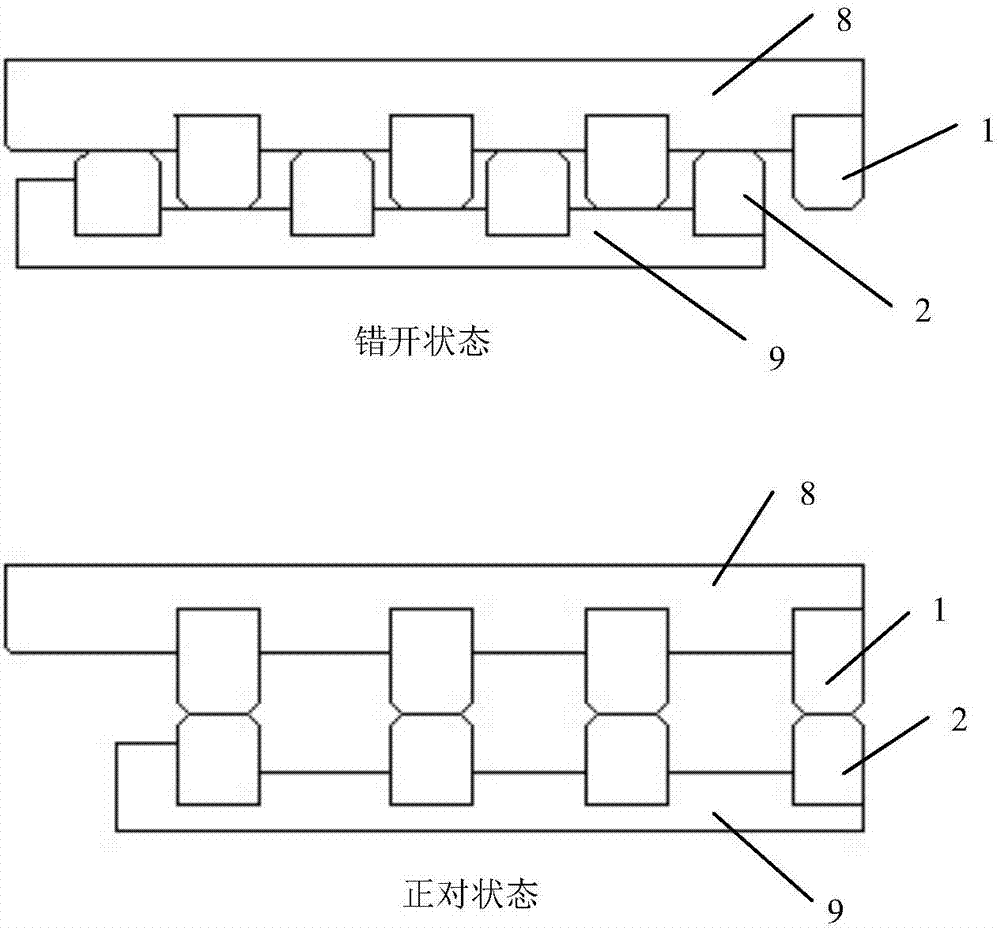

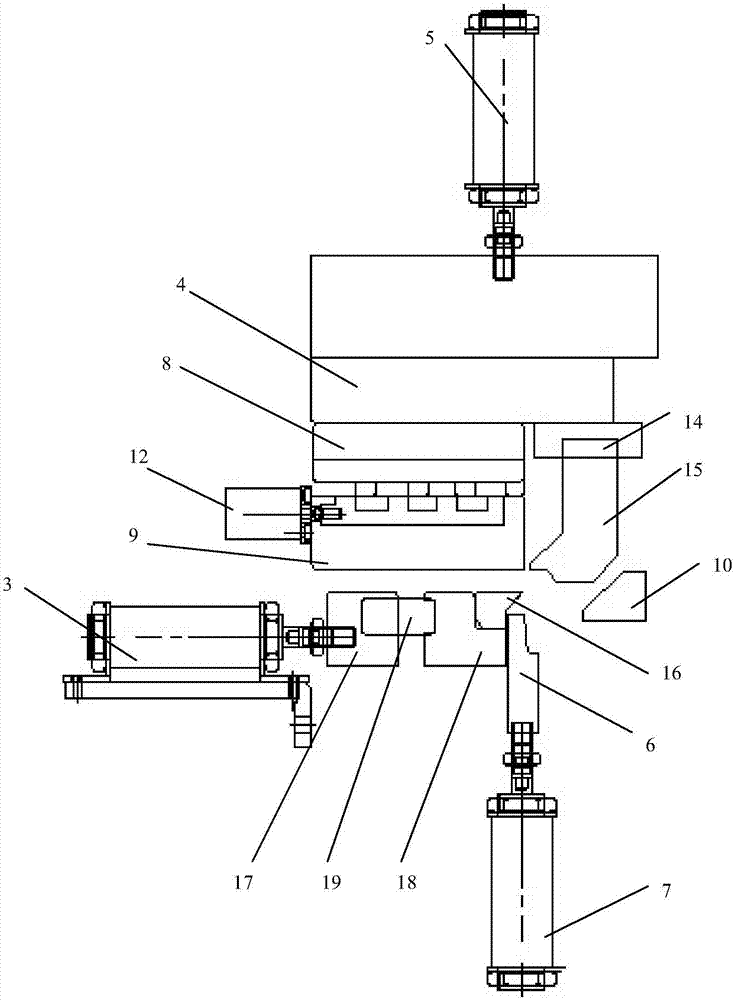

Embodiment 1

[0042] Such as image 3 and Figure 6 As shown, in this embodiment, a kind of bending flat mold is provided, and the bending flat mold includes an upper mold and a lower mold, and the upper mold includes a bending upper mold 15, a compression mold 9 and an upper mold Drive assembly; the lower die includes a bending lower die 16, a flat die 6, a lower die drive assembly and a lower die switching assembly 11; the pressing die 9 is used to compress the upper die and the lower die The sheet material between; the bending upper mold 15 and the bending lower mold 16 cooperate to complete the bending process of the sheet material, and the upper mold driving assembly is used to drive the bending upper mold 15 to move up and down; The flattening die 6 is used to complete the flattening process of the sheet material, and the lower mold driving assembly is used to drive the flattening die 6 to complete the flattening process; 6. When the flattening process is completed, the bending lowe...

Embodiment 2

[0059] Such as image 3 As shown, the bending and flattening mold provided in this embodiment is a further improvement of the bending and flattening mold provided in the first embodiment, and the technical solution described in the first embodiment also belongs to this embodiment. A technical solution that has already been described will not be described again.

[0060] Specifically, in this embodiment, a bending and flattening die is provided, which also includes an upper die switching assembly, and the upper die switching assembly is used to press the pressing die 9 and at the same time make the folding Bending upper mold 15 can avoid described clapping flat mold 6 when finishing clapping flat technology.

[0061] The scheme in the first embodiment is provided with a lower die switching assembly 11, and the lower die switching assembly 11 is used to make the bending lower die 16 avoid the flat die 6 when the flat die 6 completes the flattening process, so that the flat die ...

Embodiment 3

[0073] The bending and flattening mold provided in this embodiment is a further improvement of the bending and flattening mold provided in the first and second examples, and the technical solutions described in the first and second examples also belong to this Embodiments, the technical solutions already described in Embodiment 1 and Embodiment 2 will not be described repeatedly.

[0074] Specifically, as Figure 9 As shown, in this embodiment, a bending and flattening mold is provided, which also includes a bending guide assembly, and the bending guide assembly includes a guide rail 14, and the guide rail 14 is arranged on the upper mold drive assembly, so The end of the bending upper mold 15 away from the bending lower mold 16 is correspondingly provided with a guide groove;

[0075] Such as Figure 9 , in an optional solution of this embodiment, the bending guide assembly further includes a wedge block 10, the wedge block 10 is arranged on the lower die, and the wedge blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com