Portable clamp

A portable fixture technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problem of low coaxiality, achieve the effect of convenient processing, improve coaxiality, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

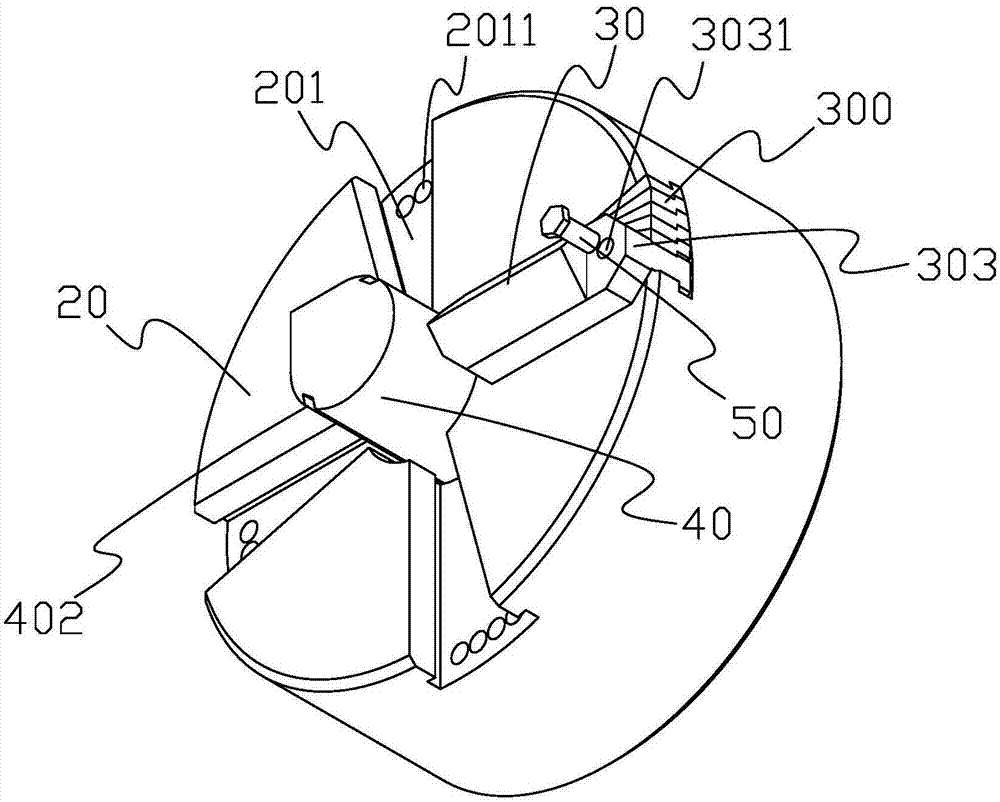

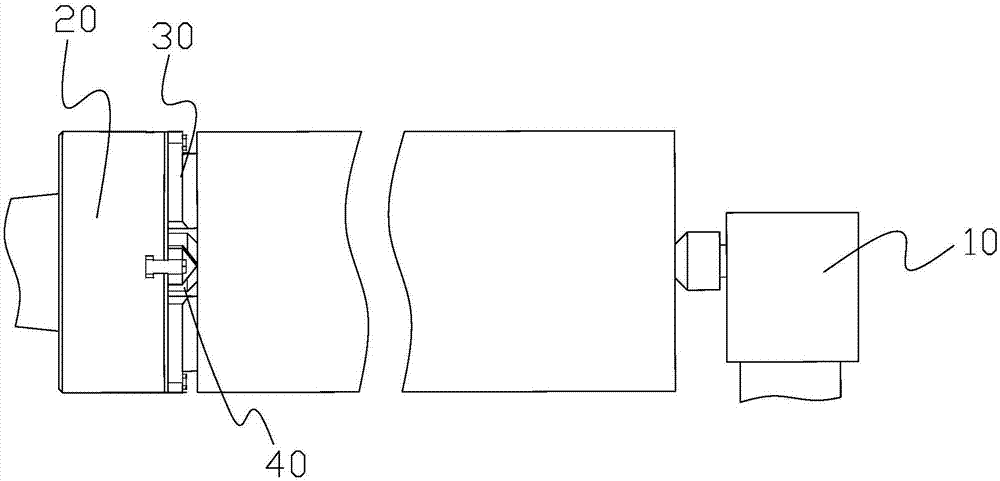

[0044] see figure 1 , figure 2 , image 3 as well as Image 6 , the present invention provides a portable fixture, comprising a tailstock center point 10, the tailstock center point is used to withstand one end of the workpiece when the lathe is clamping the workpiece, and also includes a chuck body 20, a jaw top piece 30, and a centering center point 40 and a fixing member 50; the clamping surface of the chuck body is provided with more than three jaw chutes 201, and more than three jaw chutes are all provided, and a jaw is provided on the jaw chute For the top piece, the center of the chuck body is provided with a central axis hole 202;

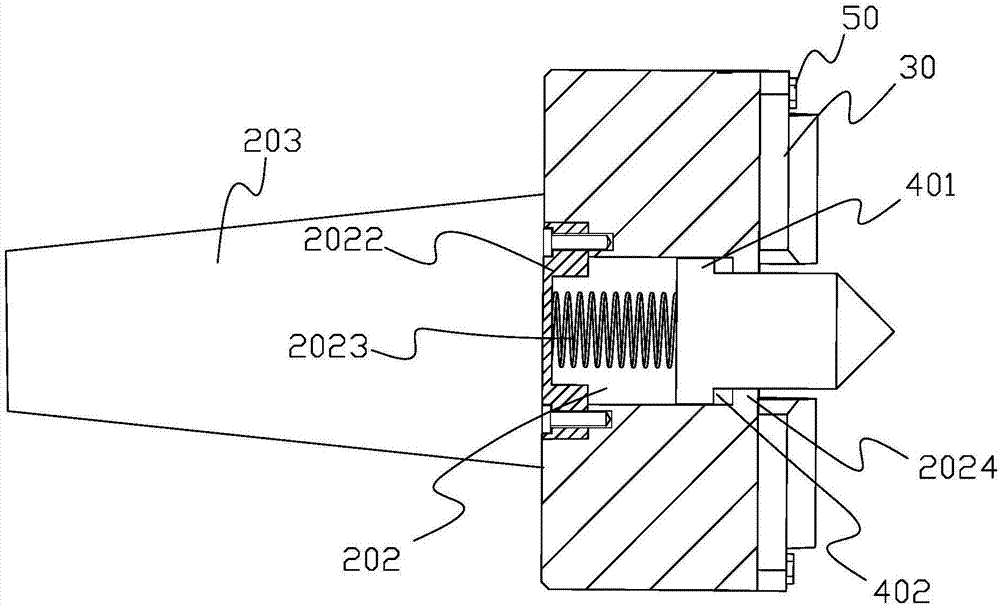

[0045] like Figure 4 and Figure 5 As shown, the jaw top piece includes an inner pad 300, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com