Automobile outer door backplane

A technology for door backs and automobiles, which is applied to doors, vehicle parts, transportation and packaging, etc. It can solve problems such as the impact of workers on assembly, achieve the effect of reducing the weight of the whole vehicle, suitable for popularization and use, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

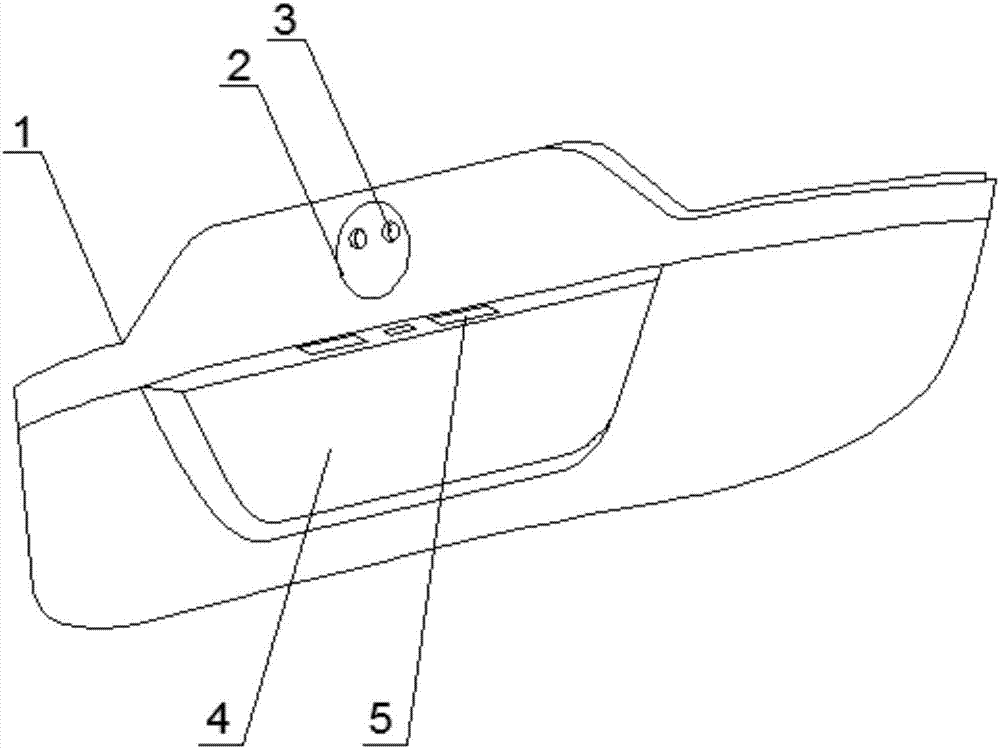

[0016] Such as figure 1 As shown, the present invention provides a back panel of an automobile exterior door, comprising a back panel body 1, a fixing groove 2, a through hole 3, a groove 4 and a cooling hole 5, the surface of the back panel body 1 is provided with a fixing groove 2, and the fixing groove 2 is provided with a through hole 3, the bottom of the fixing groove 2 is provided with a groove 4, and the top surface of the groove 4 is provided with a cooling hole 5. Self-weight, increase the style of the rear part, solve the problem that the existing new energy car body still uses the metal outer door back panel, which causes the overall weight of the car body to increase, and the problem of inconvenient assembly for workers is solved. The structure is simple and suitable for popularization and use.

[0017] The backplane body 1 is integrally formed by injection molding. The injection molding process has the advantages of fast production speed, high efficiency, automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com