Outrigger-lifting type bridge deck erecting machine and bridge deck erecting method

A trigger and rear outrigger technology, used in the erection/assembly of bridges, bridge parts, bridge maintenance, etc., can solve the multiple disassembly and assembly of equipment, the limitation of construction space height and width, and the inability to meet the installation requirements of new steel bridge decks, etc. problems, to avoid safety accidents, reduce the weight of the whole machine, and improve the stability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

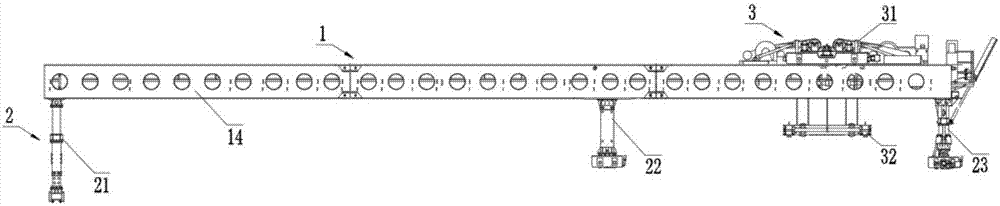

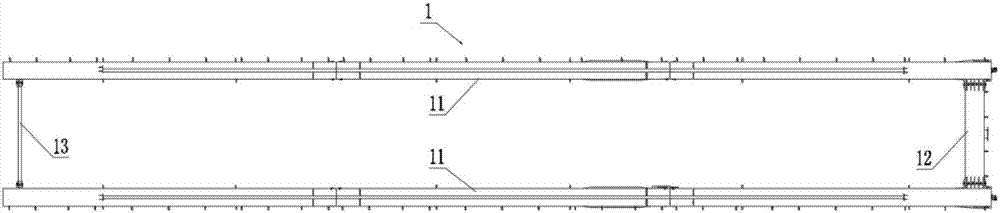

[0051] see figure 1 and figure 2 As shown, the present invention provides a leg lifter, which includes a main structure 1 , a supporting mechanism 2 , and a lifting device 3 .

[0052] The main body structure 1 comprises two opposite main beams 11, the two ends of the two main beams 11 are fixed with the first cross beam 12 and the second cross beam 13 connecting the two main beams 11, in order to prevent the main beam 11 side bending and "eight The "" character is deformed, the main beam 11 adopts a segmented structure, and the joints of two adjacent segments are connected by inner pins, which is easy to dismantle. Wherein the main girder web 14 is set as a hole structure, which reduces the windward area and improves the overall stability.

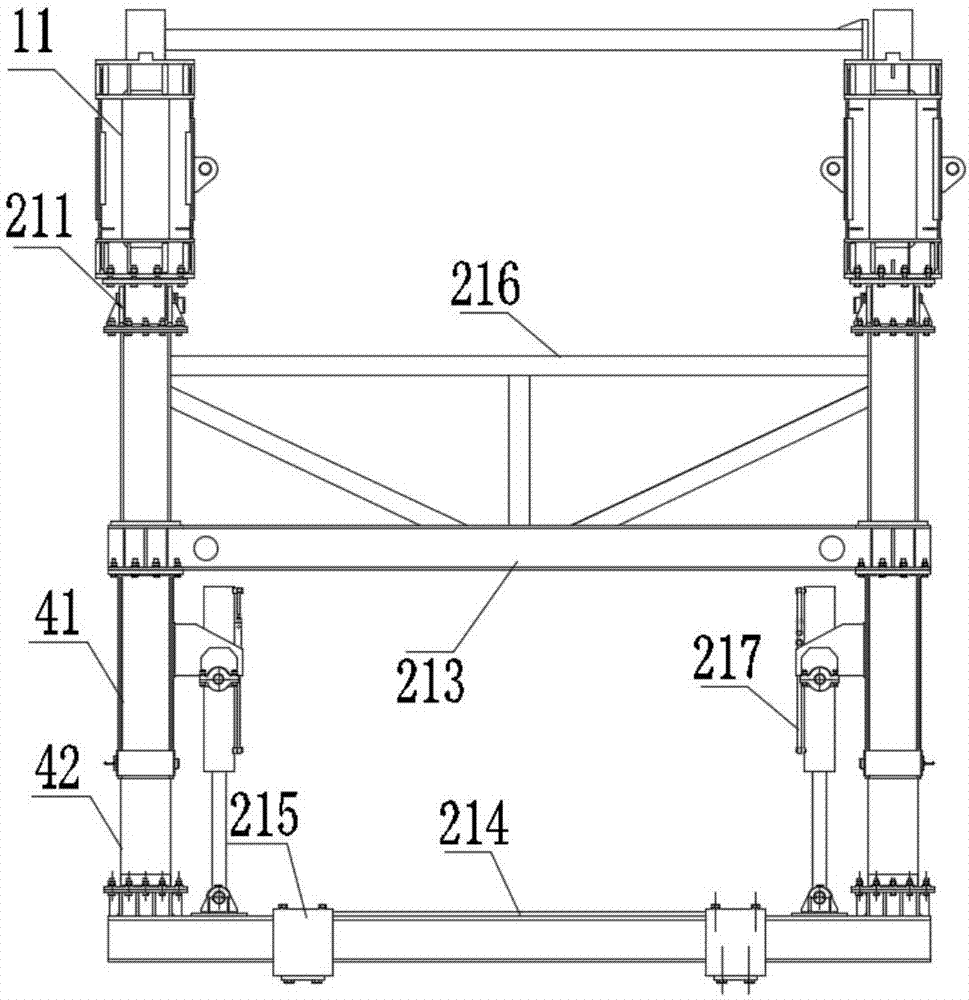

[0053]The supporting mechanism 2 includes a front leg 21 , a middle leg 22 and a rear leg 23 fixed on two main bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com