Decorative sheet fixing structure

A technology for fixing structures and decorative panels, which is applied in building construction, covering/lining, construction, etc. It can solve the problems of inconvenient construction, large glue consumption, and large maintenance of the project, so as to achieve convenient installation and replacement, shorten construction hours, The effect of reducing check-in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

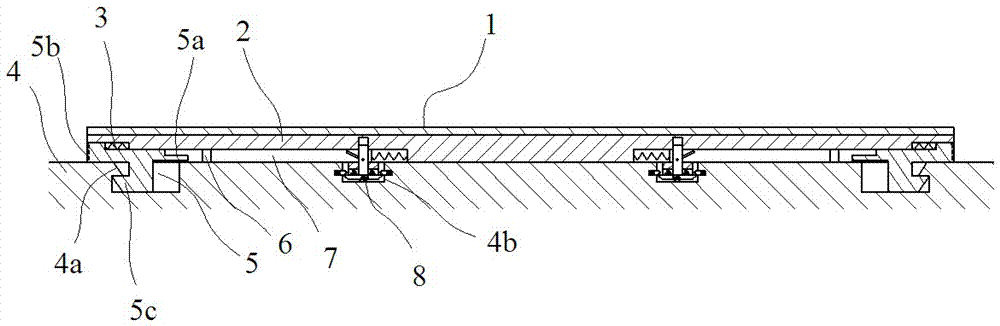

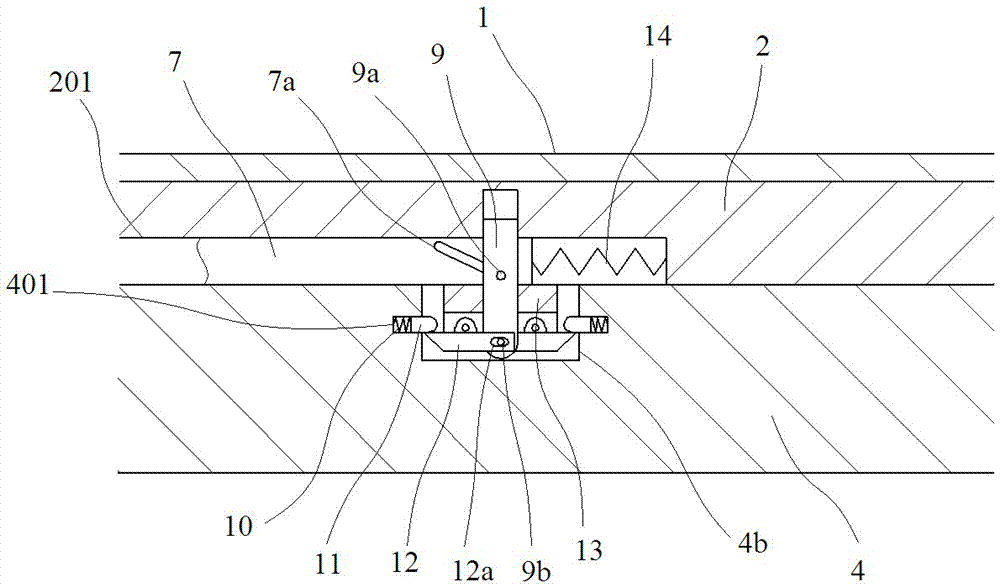

[0019] Such as figure 1 In the shown embodiment, a decorative panel fixing structure includes a panel body 2 and a positioning seat 4, wherein a surface layer 1 is provided on the upper surface of the panel body, and the positioning seat is located below the panel body. A fixing hook 4a is provided on the positioning seat, and the fixing hook corresponds to the edge position of the board body. The edge of the board body is provided with a movable buckle 5 engaged with the fixed hook, and a spring 3 is arranged between the movable buckle and the board body. The movable buckle includes a sliding part and a clamping part 5c located below the sliding part, and a guide groove slidably connected with the sliding part is provided in the plate body. The sliding part is provided with a pressing part at one end close to the edge of the plate body, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com