Axial double-acting hydraulic impactor

A double-acting impactor technology, which is applied in the drilling driving device, drilling equipment, earthwork drilling and production in the wellbore, can solve the problems of low drilling efficiency, short life of the drill bit, long drilling cycle, etc., to improve drilling efficiency, The effect of reducing drilling cost and improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

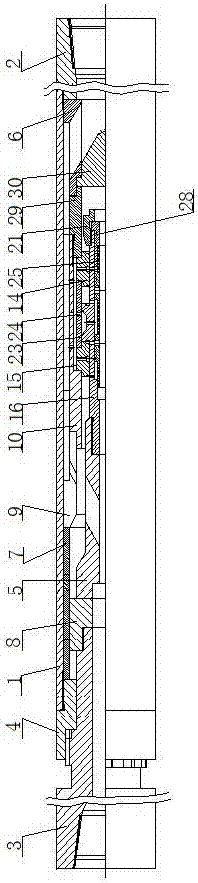

[0031] The axial double-acting hydraulic impactor includes a casing 1 , an upper joint 2 , a lower joint 3 , a spline sleeve 4 , an impact hammer body 5 and a flow guide sleeve 6 . One end of the housing 1 is threaded with an upper joint 2; the other end of the housing 1 is equipped with a lower joint 3 through a spline sleeve 4; one end of the spline sleeve 4 is threaded with the housing 1; the other end of the spline sleeve 4 is connected to the lower joint 3 key connection.

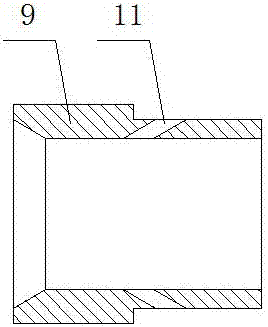

[0032] A hammer seat 8 is installed in the casing 1 through a sleeve 7, and the hammer seat 8 and the lower joint 3 are screwed together. The casing 1 on one side of the sleeve 7 is equipped with a throttling sleeve 9 and a high-pressure shunt barrel 10 , and the throttling sleeve 9 is connected to the high-pressure shunt barrel 10 . The throttle sleeve 9 is provided with a throttle sleeve hole 11; the throttle sleeve hole 11 communicates with the center hole of the throttle sleeve 9; a flange 12 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com