Bladeless impeller for steam turbine, rotor and multi-channel steam turbine

A steam turbine rotor, blade impeller technology, applied in the direction of machine/engine, stator, mechanical equipment, etc., can solve problems such as blade breakage, achieve the effect of eliminating axial force, preventing breakage, reducing difficulty and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

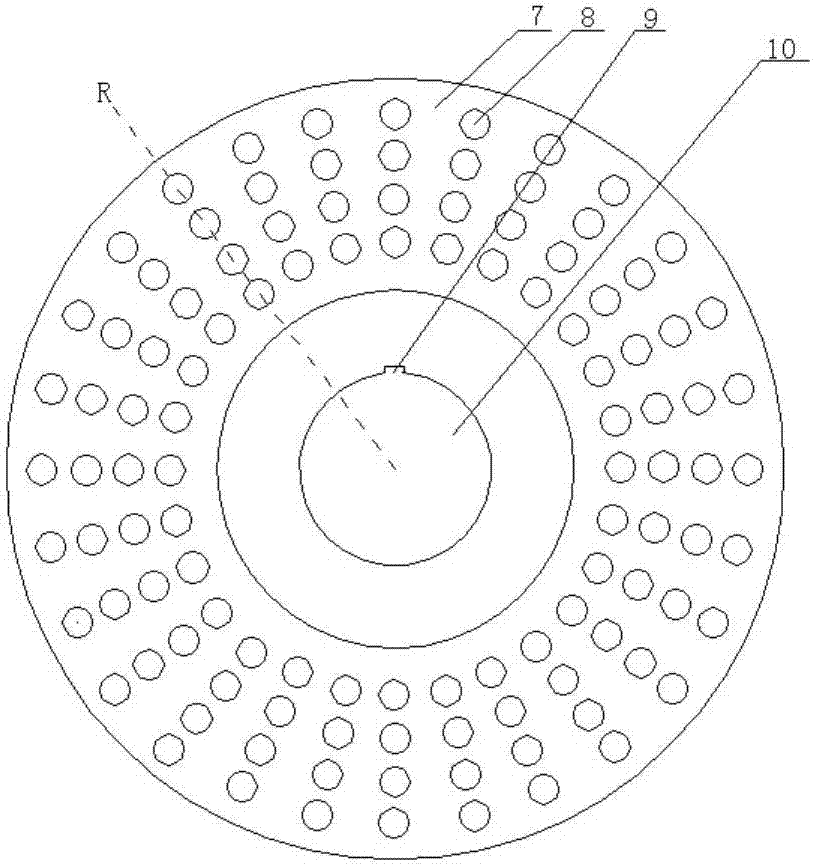

[0059] In the first aspect, the embodiment of the present application provides a bladeless impeller of a steam turbine, which includes a disc 7 provided with several rows of steam holes, and each row of steam holes includes at least one steam hole 8;

[0060] The series of steam holes surround the center of the disk 7 and are arranged circumferentially on the surface of the disk 7;

[0061] The series of steam hole groups are used to obtain energy from steam to make the disc 7 rotate.

[0062] The center of the disc 7 may be provided with a main shaft hole 10 and a keyway 9 communicating with the main shaft hole.

[0063] When each steam hole group includes a plurality of steam holes 8, such as figure 2 As shown, a plurality of steam holes 8 in the same steam hole group can be radially arranged along the radius R of the disk 7 and extend from the center of the disk 7 to the outer edge of the disk 7 . The above content is illustrative, the number of rows of steam hole groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com