Rapid thermal response composite phase change heat storage device and preparation method thereof

A composite phase change and heat storage technology, which is applied in chemical instruments and methods, heat storage equipment, indirect heat exchangers, etc., can solve the problems of long thermal response time of phase change, long thermal response time, and low heat dissipation efficiency. Achieve the effects of short phase change thermal response time, high thermal conductivity, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

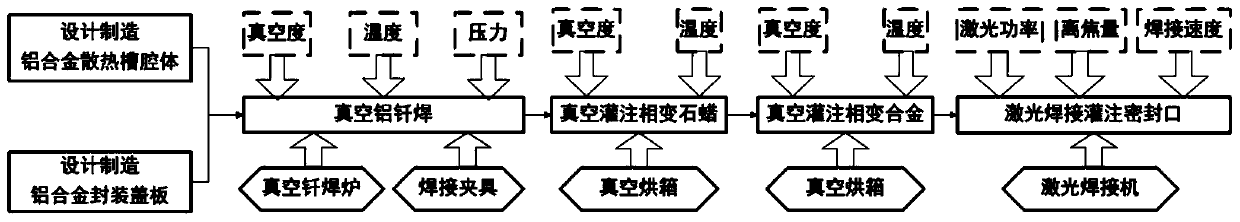

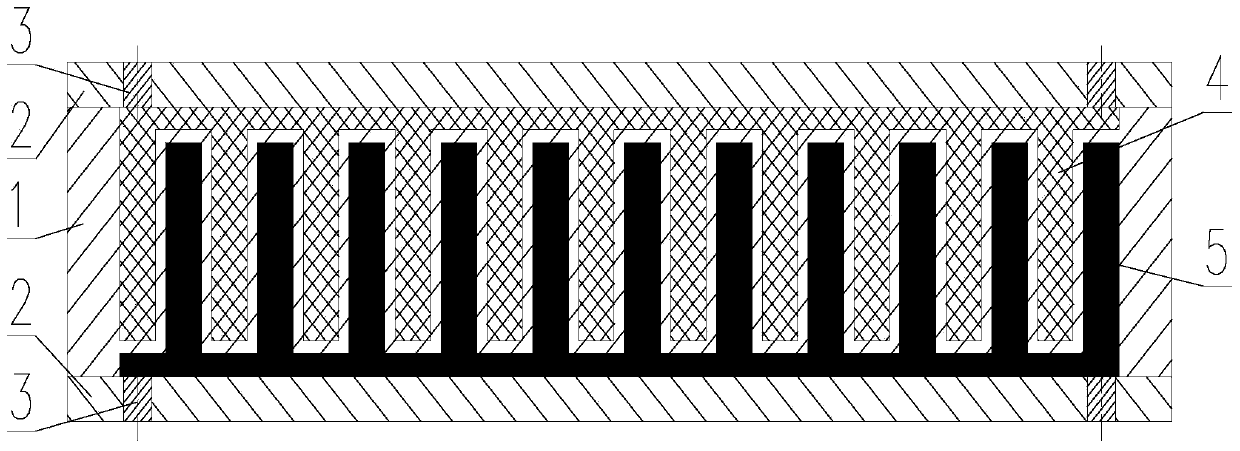

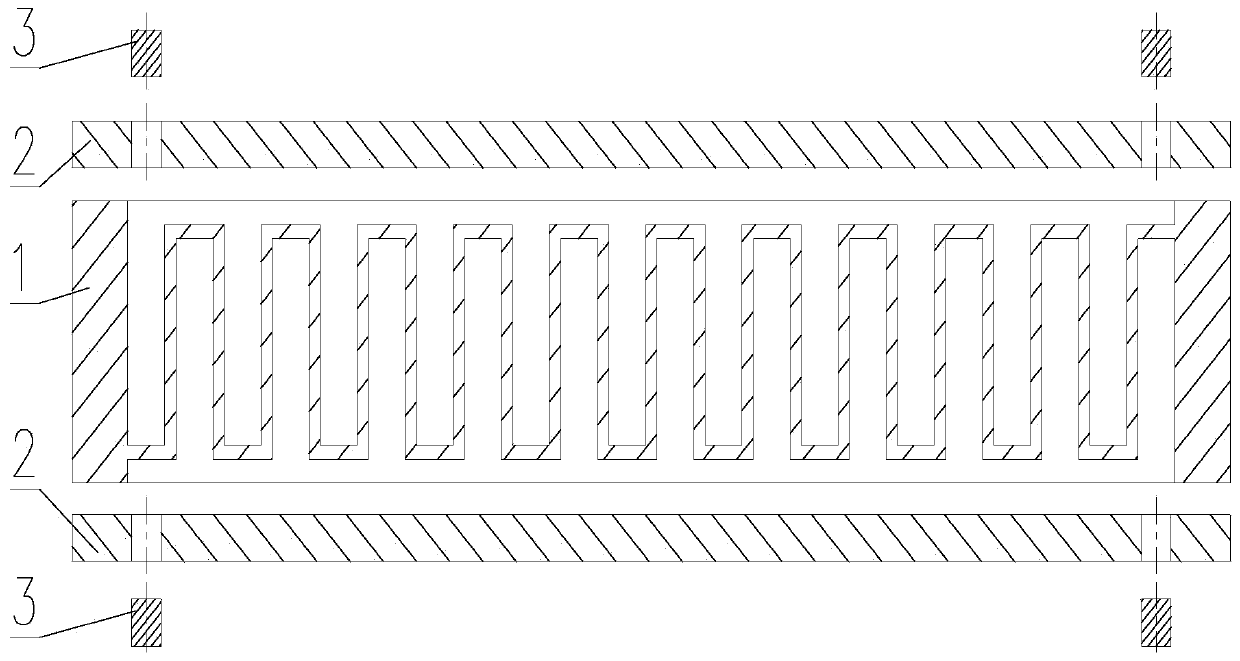

[0024] refer to Figure 1 ~ Figure 3 . In the embodiment described below, a rapid thermal response composite phase change heat storage device is composed of a heat storage container 1, an encapsulation cover plate 2, a sealing column 3, a phase change paraffin wax 4 and a phase change alloy 5. The heat storage container of phase-change paraffin and phase-change alloy, the inner cavity of the heat storage container is made of forward and reverse continuous U-shaped cooling groove cavities formed in series in a linear array sequence, wherein the forward U-shaped cooling cavity is used as a paraffin cavity, The phase-change paraffin wax 4 is poured, and the reverse U-shaped heat dissipation chamber is used as an alloy chamber, and it is filled with a phase-change alloy 5 with a thermal conductivity ≥ 15W / (m K) and a high thermal conductivity, and is sealed by the upper and lower packaging cover plates 2. High thermal conductivity phase change alloy is integrated with high enthal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com