A kind of traditional Chinese medicine fine granule and preparation method thereof

A fine-grained, traditional Chinese medicine technology, which is applied in pharmaceutical formulations, drug combinations, and medical preparations containing active ingredients, etc., can solve the problems of poor solubility, inconvenience in taking traditional Chinese medicine preparations for soothing the liver and relieving depression, and difficult to meet the needs of patients for medication, etc. Easy to take, excellent melting properties, and the effect of improving medication compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

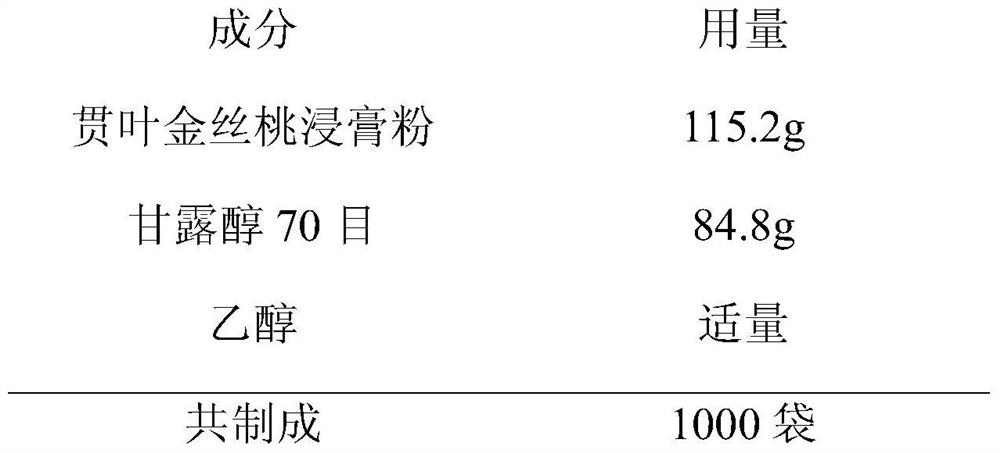

[0074]

[0075] 1. Take Hypericum perforatum extract powder and dissolve it in an appropriate amount of ethanol to obtain extract liquid, pass through an 80-mesh sieve, and set aside.

[0076] 2. Put mannitol into the WBF-3G fluidized bed, and set the air intake to 40-50m 3 / h, the air inlet temperature is 35-45°C, the atomization pressure is 0.8-1.2bar, the material temperature is 35-45°C, and the extract is sprayed at a speed of 5-20g / ml.

[0077] 3. After the liquid spraying is finished, the prepared particles are sieved, and the fine particles that meet the required particle size are screened out.

Embodiment 2

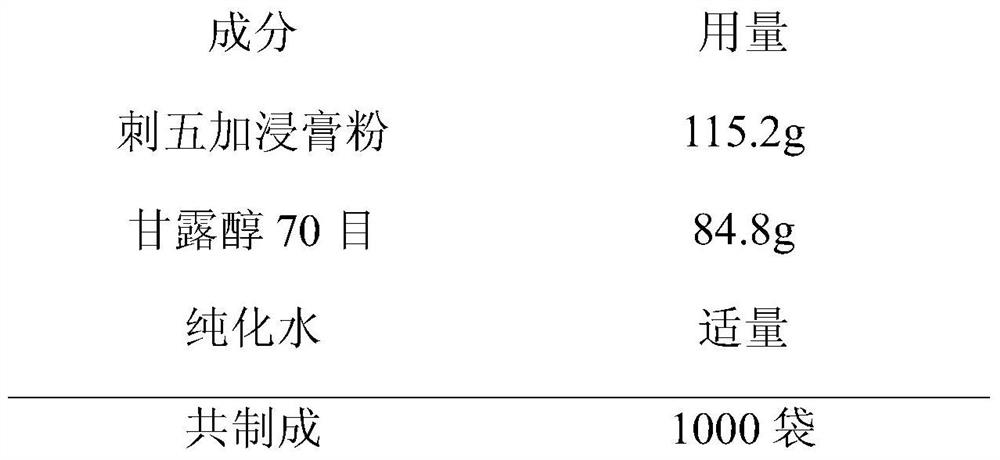

[0079]

[0080] 1. Dissolve Acanthopanax extract powder in an appropriate amount of purified water to obtain an extract liquid, pass through a 80-mesh sieve, and set aside.

[0081] 2. Put mannitol into the WBF-3G fluidized bed, and set the air intake to 40-50m 3 / h, the air inlet temperature is 35-45°C, the atomization pressure is 0.8-1.2bar, the material temperature is 35-45°C, and the extract is sprayed at a speed of 5-20g / ml.

[0082] 3. After the liquid spraying is finished, the prepared particles are sieved, and the fine particles that meet the required particle size are screened out.

Embodiment 3

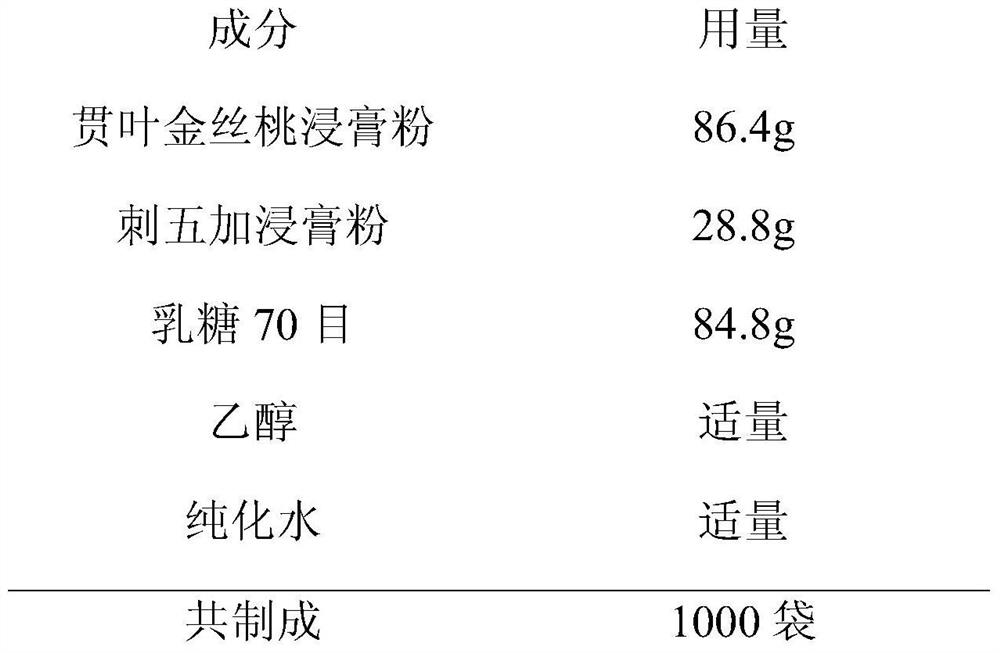

[0084]

[0085] 1. Get hypericum perforatum extract powder and dissolve in appropriate amount of 75% ethanol, get Acanthopanax acanthopanax extract powder and dissolve in appropriate amount of purified water, mix both uniformly to obtain mixed extract solution. Pass through a 80-mesh sieve and set aside.

[0086] 2. Put lactose 70 mesh into the WBF-3G fluidized bed, set the air intake to 40-50m 3 / h, the air inlet temperature is 35-45°C, the atomization pressure is 0.8-1.2bar, the material temperature is 35-45°C, and the mixed extract is sprayed at a speed of 5-20g / ml.

[0087] 3. After the liquid spraying is finished, the prepared particles are sieved, and the fine particles that meet the required particle size are screened out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com