Powder mixing device and powder mixing method

A mixing device and powder technology, applied in mixers, fluid mixers, chemical instruments and methods, etc., can solve problems such as affecting the quality of laser cladding, large fluctuations in powder feeding rate, affecting work efficiency, etc., to save resources , the effect of increasing the mixing quality and improving the cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams.

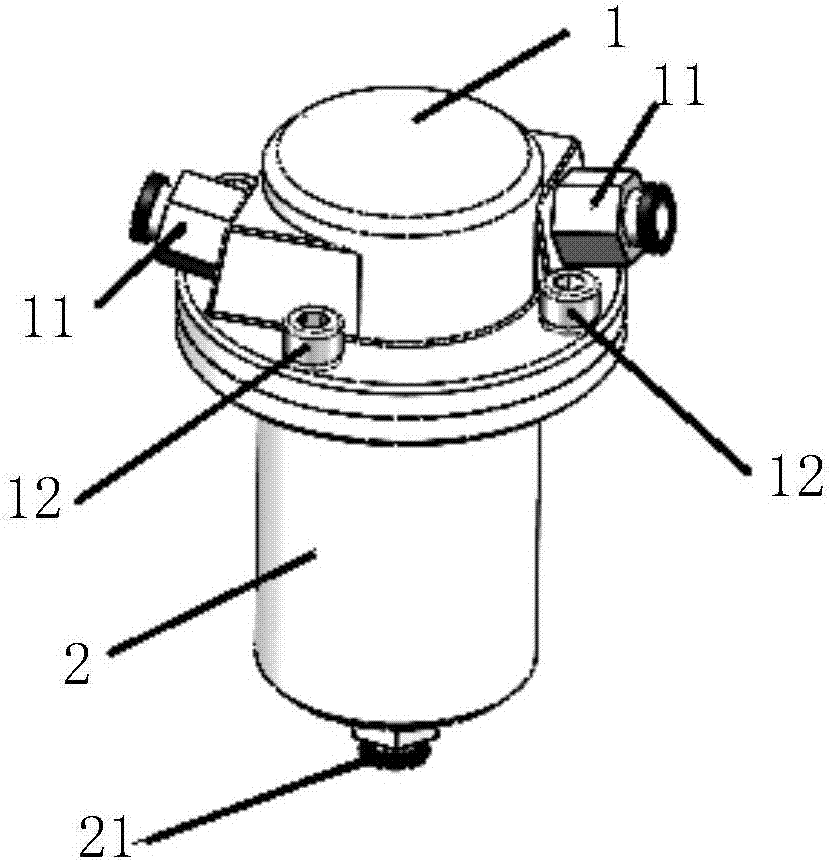

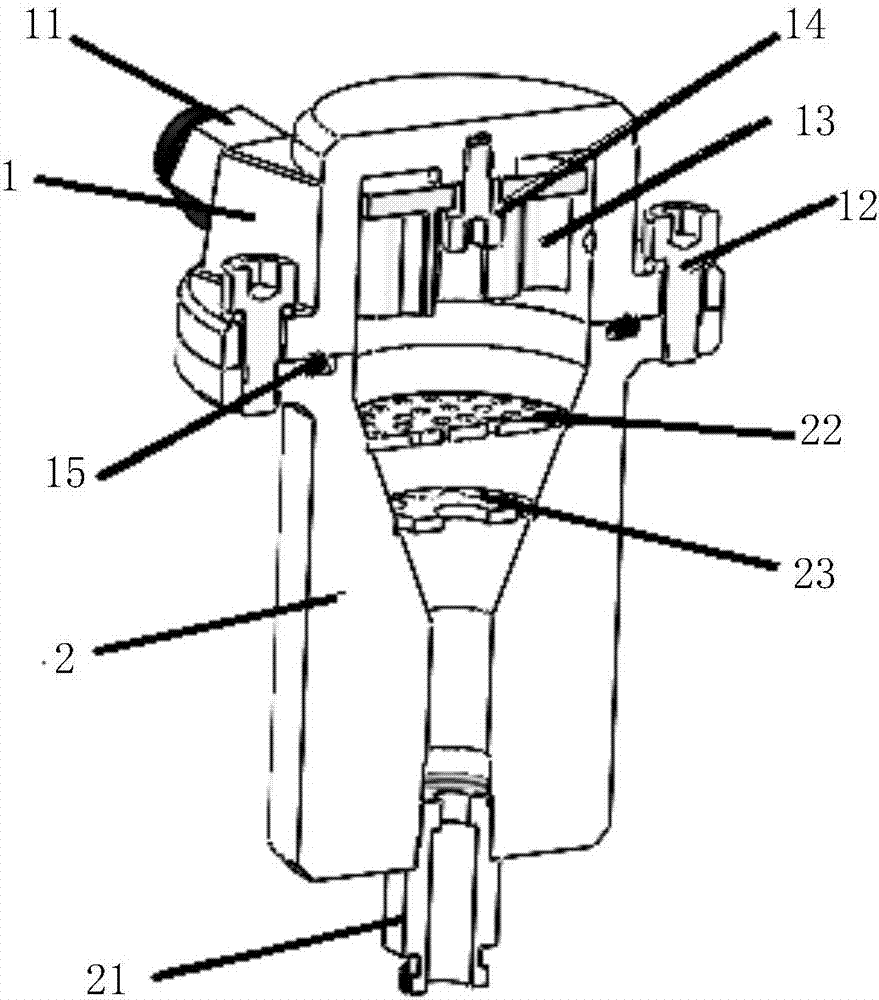

[0030] The present invention proposes a powder mixing device and method for mixing multiple powders to be mixed, wherein the powder mixing device includes: a cover and a detachably connected body, such as figure 1 As shown, specifically, the cover and the body are connected through detachable components, and further, are detachably connected through fastening screws and gaskets 12. The present invention does not impose any restrictions on the detachable connection parts of the cover 1 and the body 2 . In order to increase the sealing performance of the inner cavity of the cover body 1 and the body 2, the powder mixing device in this embodiment also includes a sealing ring 15, and the present invention does not impose any restrictions on its material quantity, material and shape.

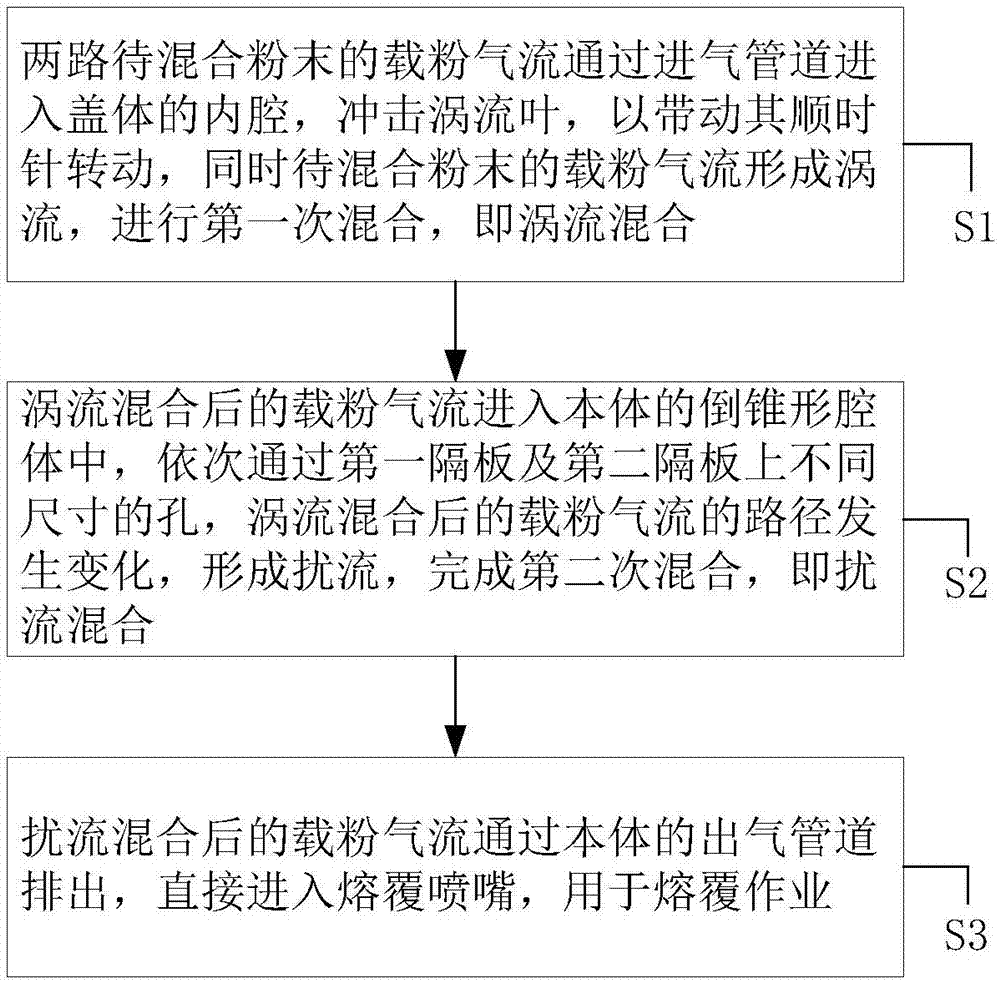

[0031] When the powder-carrying airflow of multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com