Secondary gas-liquid two-phase flow electrostatic nozzle

A two-phase flow and secondary gas technology, which is applied in electrostatic spraying devices, liquid spraying devices, spraying devices, etc., can solve the problems of small fog droplets that are easy to drift away, cannot be changed, and large fog droplets are easy to lose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

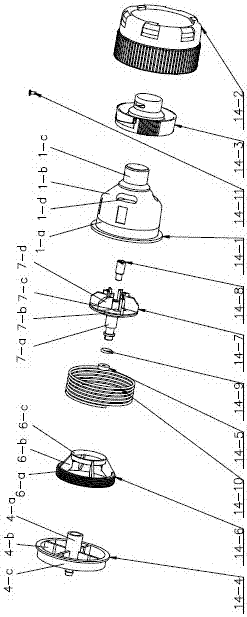

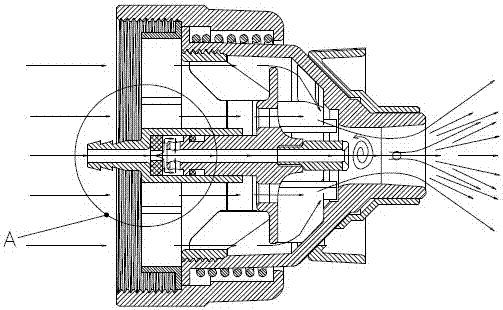

[0024] The secondary gas-liquid two-phase flow electrostatic nozzle of the present embodiment is as follows: figure 1 , 2 As shown, it includes the support 14-4 and the nozzle cap 14-1 that are pressed and pressed at the end of the fluid delivery pipe through the internal thread connection at the inner end of the cap 14-2 during installation. The bracket 14-4 is composed of a central infusion tube 4-a and a ring 4-c connected with the infusion tube 4-a through a group of radial webs 4-b, and one end of the ring 4-c has a radial The extended rib is pressed and fixed on the end of the fluid delivery pipe by the cap. Nozzle cap 14-1 is made of cap tube 1-a and the discharge tube 1-c with diffuser mouth that is connected with cap tube 1-a by contraction cone 1-b, and the inner end of its cap tube 1-a has Radially extend the flanging, and a spring 14-10 is housed between the flanging and the spigot at the outer end of the cap 14-2, so it is held elastically.

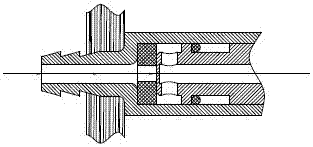

[0025] The screw n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com