Suspension mechanism provided with hub motor

A hub motor and suspension technology, which is applied in the direction of suspension, elastic suspension, steering mechanism, etc., can solve the problems of poor vehicle handling performance, tight wheel arrangement of suspension structure, etc., and achieve compact arrangement of wheel edges, ensure strength and Rigidity, the effect of ensuring handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure of the present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

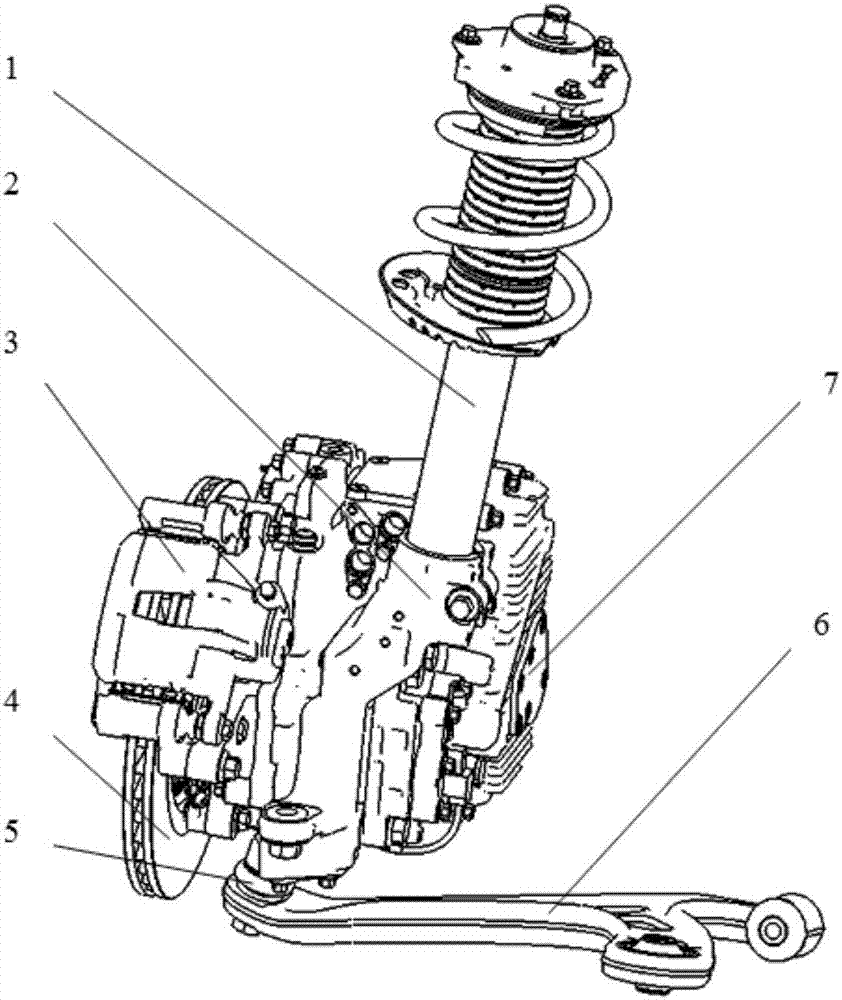

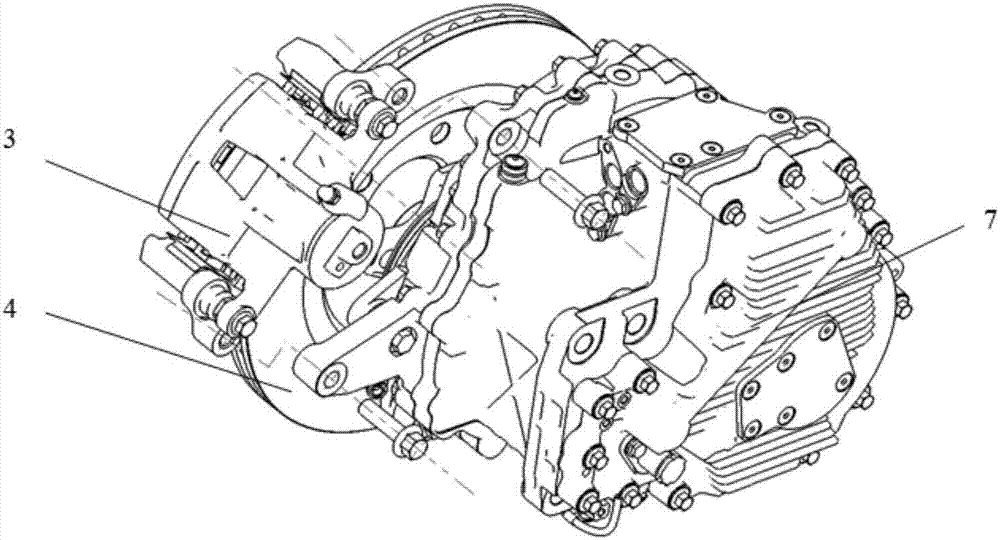

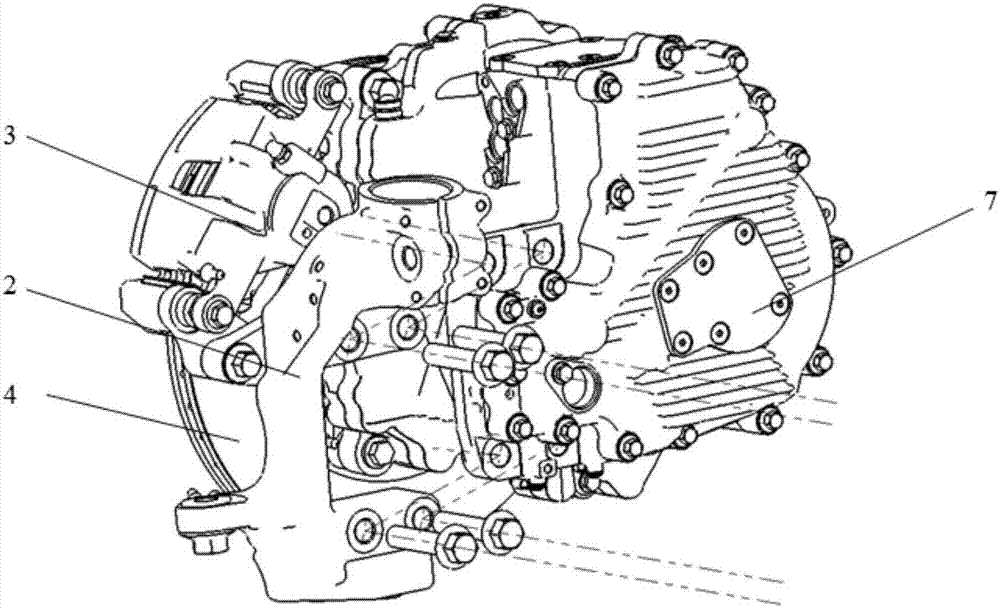

[0015] refer to Figures 1 to 5 , a suspension structure equipped with a hub motor, including a strut 1, a steering knuckle 2, a brake caliper 3, a brake disc 4, a ball joint assembly 5, a control arm 6 and a hub motor 7; the brake caliper 3 is threaded Fixedly connected to the shell of the hub motor 7, the brake disc 4 is set on the bearing unit of the hub motor 7, and the steering knuckle 2 is used as a wheel side bracket in a C-shape. The body is fastened by bolts; the upper end of the steering knuckle 2 is clamped to the sliding column 1 through bolts, and the lower end is fixedly connected with the shell of the ball joint assembly 5 through three-point internal threads, and the ball stud pin of the ball joint assembly 5 passes through the taper surface. It is interference fit with the control arm 6, and the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com